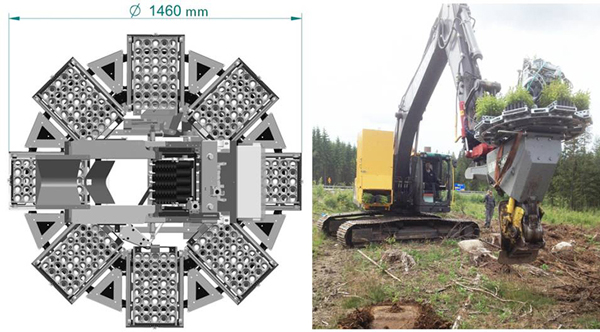

Fig. 1. Top view drawing of the MagMat tray carousel (left) and the test-rig mounted on a Bracke Planter during the field testing (right). Note that the test-rig lacks a protective barrier around the carousel. Photo and drawing: Rikard Wennberg.

Fig. 2. Loading a Hiko cultivation tray onto one of MagMat’s eight frames. Photo: Rikard Wennberg.

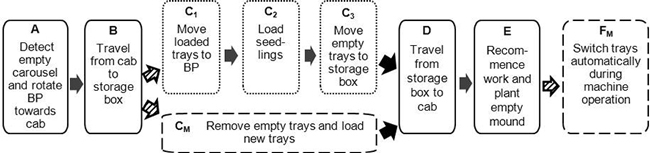

Fig. 3. Flowchart of the work elements involved in reloading the Bracke Planter (BP) with seedlings. Dotted- and dashed-border boxes represent work elements exclusive to the 70Car and MagMat carousels respectively, while elements common to both carousels have a solid border.

| Table 1. Baseline cost factors for the base machine and Bracke Planter planting device. | ||

| Factor | Unit a) | Value |

| Mid-sized tracked excavator | ||

| Purchase price including seedling storage box | Euro | 172 200 |

| Full labour costs including operator travel costs | Euro SMh–1 | 32 |

| Insurance and administration | Euro SMh–1 | 2 |

| Maintenance, lubrication and fuel costs | Euro PWh–1 | 18.5 |

| Scheduled time | SMh yr–1 | 1600 |

| Bracke Planter planting device | ||

| Purchase price | Euro | 55 560 |

| Maintenance costs | Euro PWh–1 | 2.1 |

| Scheduled time | SMh yr–1 | 1200 |

| a) SMh = Scheduled Machine hour; PWh = Productive Work hour; yr = year | ||

| Table 2. Parameter values for the Bracke Planter and M-Planter used in the baseline and sensitivity analysis. | |||||

| Parameter | Unit a) | Baseline value | Sensitivity analysis | ||

| Bracke Planter | M-Planter | Minimum | Maximum | ||

| Mean planting time excluding seedling reloading | s pl–1 | 14.9 b) | 13.0 c) | –40% | +30% |

| Fixed costs (including full labour costs) | Euro SMh–1 | 58.0 | 61.0 | –10% | +40% |

| Variable costs | Euro PWh–1 | 20.5 | 20.8 | –10% | +40% |

| Interest rate | % | 5 | 5 | 3 | 10 |

| Opening/closing protective barrier on MagMat | s reload–1 | 10 | 10 | 0 | 60 |

| Automatic tray switching time | s tray–1 | 25 | 25 | 0 | 60 |

| Mechanical availability (MA) of MagMat | % | 100 | 100 | 80 | 100 |

| a) pl = seedling; SMh = Scheduled Machine hour; PWh = Productive Work hour b) from Ersson et al. (2011) c) based on values from Rantala et al. (2009) | |||||

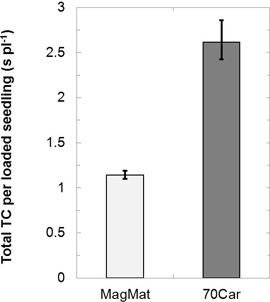

Fig. 4. The mean total time consumption (TC) per loaded seedling for the standard Bracke Planter seedling carousel (70Car) and MagMat tray carousel. MagMat’s TC includes an assumed 10 s per reload for opening/closing a protective barrier. Vertical bars delineate the range of means for the landing time study’s three operators.

| Table 3. Average time consumption (TC) values and ranges per work element when three different operators reloaded seedlings during the time study. | |||

| Work element abbreviation in Fig. 3 | Work element | Mean TC per reload (s) | Range of TC per reload (s) |

| Common elements for both carousels | |||

| A | Detect empty carousel and rotate planting device | 13 | 8–15 |

| B + D | Travelling to and from cab – seedling storage box | 36 | 27–46 |

| E | Recommence work and plant in empty mound | 15 | 14–20 |

| 70Car (70 seedlings per reload) | |||

| C1 + C3 | Moving trays between storage box and carousel | 14 | 9–20 |

| C2 | Seedling reloading | 105 | 94–115 |

| Total for 70Car | 183 | 170–200 | |

| MagMat (320 seedlings per reload) | |||

| CM | Reloading trays including moving trays between storage box and carousel and removing empty trays | 90 a) | 83–99 a) |

| FM | Automatic tray switching during machine operation | 200 | 192–264 |

| Total for MagMat | 354 a) | 303–410 a) | |

| a) Not including an assumed 10 s per reload for opening/closing protective barrier | |||

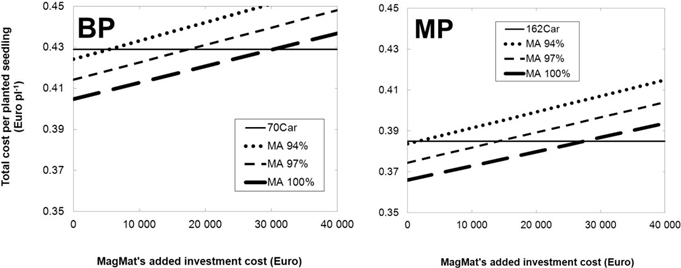

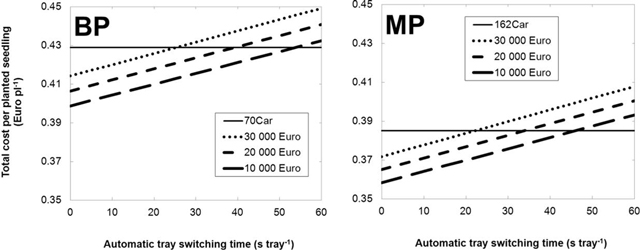

Fig. 5. Total cost per planted seedling of the Bracke Planter (BP) and M-Planter (MP) as a function of the added investment cost for MagMat and its mechanical availability (MA). 70Car and 162Car are the current seedling carousels for the Bracke Planter and M-Planter respectively. Note: the y-axes have been truncated.

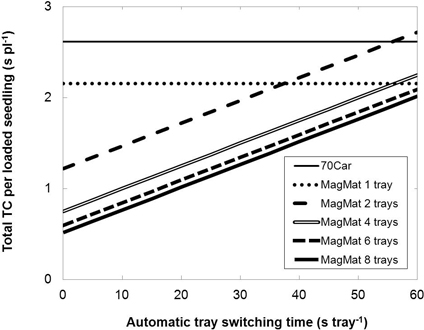

Fig. 6. Total cost per planted seedling of the Bracke Planter (BP) and M-Planter (MP) as a function of how quickly seedling trays can be switched automatically on the MagMat tray carousel and its added investment cost (assuming 100% MA). 70Car and 162Car are the current seedling carousels for the Bracke Planter and M-Planter respectively. Note: the y-axes have been truncated.

Fig. 7. The time consumption (TC) of various MagMat capacities as a function of how quickly seedling trays can be switched automatically for configurations with more than one tray. Mechanical availability (MA) is assumed to be 100% and that the TC for applicable work elements equal the mean values presented in Table 3.