| Table 1. Overview of method applied based on the different parts of the purpose. | |||

| Purpose | Data collection method | Validation method | Analysis method |

| Purpose part 1; identifying work order information components in harvesting | Semi-structured interviews with logging contractors | Focus group with national trade association | Qualitative data analysis; open coding |

| Purpose part 2; identifying order information quality dimensions in harvesting | Literature study, structured interviews with experts (academic and professional) | Structured interviews with logging industry experts | Qualitative data analysis; selective coding |

| Purpose part 3; assessing work order information quality in harvesting | Survey with logging contractors | Structured interviews with logging industry representative | Quantitative data analysis; frequencies, mean, st. dev., ANOVA and factor analysis using SPSS |

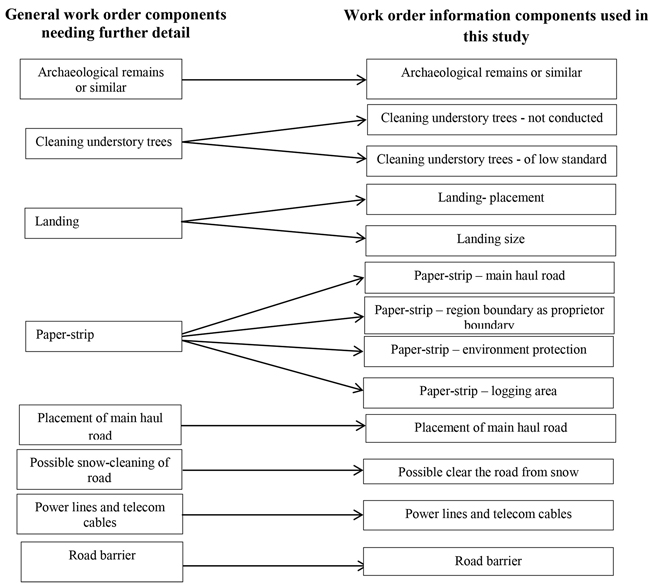

Fig. 1. Forest harvesting work order components and their origins (general work order components).

| Table 2. Information regarding respondents. | |

| Total number of certified logging contractors | 958 |

| Sample size | 100 |

| Shouldn’t have been on the list (for instance, gone out of business or changed focus area) | 3 |

| Respondents not willing to participate | 5 |

| Respondents not answering despite three calls | 10 |

| Number of answers | 82 |

| Response rate | 82% from the sample, 8.5% from the complete list |

| Table 3. Frequencies observed for each individual work order information component in harvesting. | |

| Work order information coponent | Frequencies observed |

| Archaeological remains or similar* | 6 |

| Cleaning understory trees – not conducted | 6 |

| Cleaning understory trees – of low standard | 6 |

| Landing – placement | 6 |

| Landing – size | 6 |

| Paper-strip – main haul road | 6 |

| Paper-strip – region boundary asproprietor boundary | 2 |

| Paper-strip – environment protection | 4 |

| Paper-strip – logging area | 5 |

| Placement of main haul road* | 6 |

| Possible clear the road from snow* | 6 |

| Power lines and telecom cables* | 6 |

| Road barrier* | 6 |

| * = General work order information components identified in the harvesting work order. | |

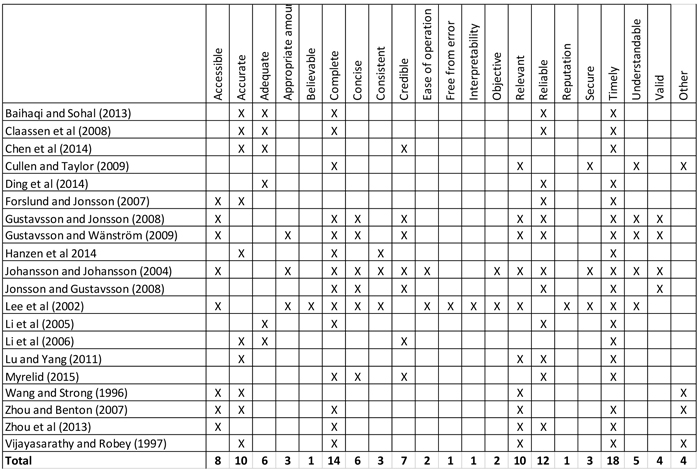

| Table 4. Overview of empirical studies including applied information quality dimensions. |

| Table 5. Descriptive statistics for the time information quality dimension. | |||

| No of days | No of respondents – Ordinary circumstances | No of respondents – In the best of cases | No of respondents – In the worst of cases |

| 0 | 25 | ||

| 1 | 23 | ||

| 2 | 3 | 3 | 11 |

| 3 | 1 | ||

| 4 | 1 | ||

| 5 | 5 | 3 | 5 |

| 6 | 1 | ||

| 7 | 2 | 3 | 16 |

| 8 | 3 | ||

| 9 | |||

| 10 | 10 | 3 | |

| 11 | |||

| 12 | |||

| 13 | |||

| 14 | 35 | 8 | 1 |

| 15 | 2 | 7 | |

| 16 | |||

| 17 | |||

| 18 | 2 | ||

| 19 | |||

| 20 | 2 | 3 | |

| 21 | 11 | 27 | |

| 22 | |||

| 23 | |||

| 24 | |||

| 25 | 2 | ||

| 26 | |||

| 27 | |||

| 28 | 5 | 19 | |

| 29 | |||

| 30 | 4 | ||

| Total | 82 | 82 | 82 |

| Min | 2 | 2 | 0 |

| Max | 28 | 30 | 14 |

| Average | 14 | 20 | 2 |

| SD | 6.1 | 7.5 | 3.1 |

| SD = standard deviation | |||

| Table 6. Descriptive statistics for the accuracy information quality dimension with regard to each specific work order information component. | ||

| Work order information component | Mean | SD |

| Paper-strip – environment protection | 6.50 | .878 |

| Paper-strip – region boundary as proprietor boundary | 6.40 | 1.132 |

| Road barrier | 6.37 | 1.319 |

| Paper-strip – logging area | 6.18 | 1.353 |

| Possible snow-clearing of road | 6.10 | 1.682 |

| Power lines and telecom cables | 5.93 | 1.858 |

| Archaeological remains or similar | 5.88 | 1.927 |

| Placement of main haul road | 5.63 | 1.836 |

| Paper-strip – main haul road | 5.67 | 1.925 |

| Landing – placement | 5.05 | 1.930 |

| Cleaning understory trees – not conducted | 4.93 | 2.193 |

| Cleaning understory trees – of low standard | 3.77 | 2.145 |

| Landing – size | 2.78 | 1.693 |

| SD = standard deviation. | ||

| Table 7. Identification of significant different means using ANOVA (Bonferroni’s pair wise comparison), in alphabetical order. | |

| Work order information component | Significant different with variable |

| Archaeological remains or similar | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Cleaning understory trees - not conducted | Archaeological remains or similar Landing – size Paper-strip – environment protection Paper-strip – logging area Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Cleaning understory trees - of low standard | Archaeological remains or similar Landing – size Paper-strip – environment protection Paper-strip – logging area Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Landing – placement | Landing – size Paper-strip – environment protection Paper-strip – logging area Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Landing – size | Archaeological remains or similar Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Paper-strip – environment protection Paper-strip – logging area Paper-strip – main haul road Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Paper-strip – environment protection | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Paper-strip – logging area | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Paper-strip – main haul road | Landing – size |

| Paper-strip – region boundary as proprietor boundary | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Placement main haul road | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Possible snow-clearing of road | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Power lines and telecom cables | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Road barrier | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Table 8. Rotated factor matrix. | |||||

| Component | |||||

| 1 | 2 | 3 | 4 | 5 | |

| Paper-strip – region boundary as proprietor boundary | .873 | ||||

| Paper-strip – logging area | .831 | ||||

| Paper-strip – main haul road | .656 | ||||

| Power lines and telecom cables | .873 | ||||

| Archaeological remains or similar | .834 | ||||

| Cleaning under story trees (not conducted) | .649 | ||||

| Cleaning under story trees (of low standard) | .854 | ||||

| Landing – size | .729 | ||||

| Landing – placement | .400 | ||||

| Paper-strip – environment protection | .794 | ||||

| Placement of main haul road | .706 | ||||

| Road barrier | .791 | ||||

| Possible snow-clearing of road | .753 | ||||

| Extraction method: Principal Component Analysis; Rotation method: Varimax with Kaiser Normalization. | |||||

| Table 9. Mean of work order information components for each factor and internal ranking of the of the respective factor (starting with highest mean value). | ||

| Original factor name | Mean | Internal ranking |

| Factor 1 | 6.083 | 2 |

| Factor 2 | 5.905 | 4 |

| Factor 3 | 4.132 | 5 |

| Factor 4 | 6.065 | 3 |

| Factor 5 | 6.250 | 1 |

| Table 10. Application in the harvesting industry of five identified information quality dimensions, based on interviews with experts. | |||||

| IQ dimension | Definition | Source | Related to harvesting industry | ||

| Accurate | Free from obvious mistakes | Forslund and Jonsson (2007) | The information should be accordance with reality. Even if the work order is downloaded from the web portal, it needs to reflect the current situation. | ||

| Complete | The extent to which the information is comprehensive | Gustavsson and Jonsson (2008) | The work order and instructions should be understandable for the person conducting the harvesting. The work order contains predefined fields and these are to be comprehensible for the logging contractor. The information quality regarding the completeness of the separate work orders is considered to be rather high; therefore, completeness with regard to information quality will not be assessed further in this study. | ||

| Relevant | The extent to which the information is appropriate for the task and application | Gustavsson and Jonsson (2008) | The work order and attached information should be designed so all needed information is included. It is not possible for the sender to load the work order on the web portal if all fields are not filled in. The information quality regarding the relevance of the separate work orders is considered to be rather high; therefore, relevance with regard to information will not be assessed further in this study. | ||

| Reliable | The probability that the forecast remains unchanged | Gustavsson and Jonsson (2008) | When logging contractors and timber buyers close annual agreements, they do not have discussions regarding the specific work orders. The information quality regarding the reliability of the separate work orders is considered to be rather high; therefore, reliability with regard to information will not be assessed further in this study. | ||

| Timely | Arrives in agreed time | Gustavsson and Jonsson (2008) | The logging contractor and the timber buyer close an agreement on when the work order should be sent to the contractor, normally 2 weeks in advance. Information regarding each work order information component is received together. If the logging contractor has not received the work order, it is impossible to conduct the logging work. The relevance of timeliness is with regard to the work order and not the individual work order components. | ||

| Table 11. Tentative factor characteristics. | |||

| Original factor name | Nature | Type of work preparatory*/ necessity** | Value when conducting work for the logging contractor |

| Factor 1 | Administrative | Preparatory | Prerequisite |

| Factor 2 | Administrative | Preparatory | N.A. |

| Factor 3 | Administrative | Preparatory | Prerequisite |

| Factor 4 | Administrative | Preparatory | Facilitation Prerequisite |

| Factor 5 | Practical | Necessity | N.A. |

| * = preparations the timber buyer is expected to have done before harvesting. ** = necessity in order for the logging contractor to access the area to be harvested. | |||

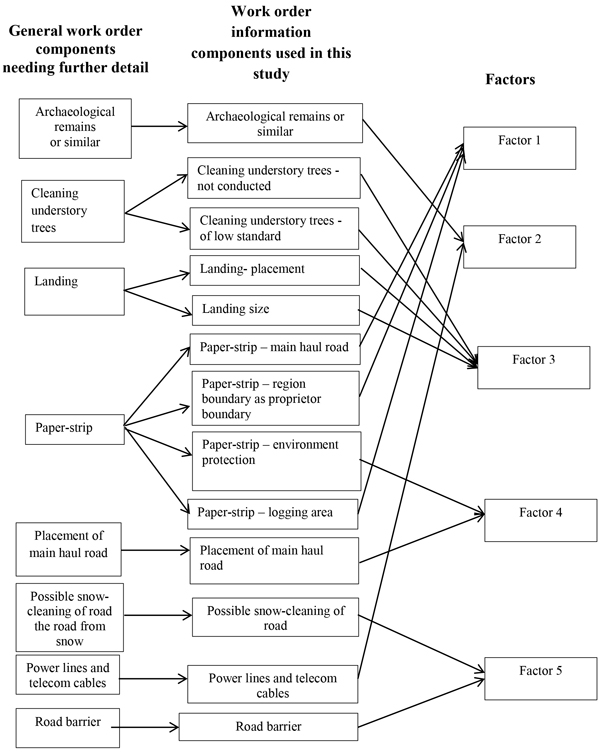

Fig. 2. Overview of result of the study.