Effect of multi-tree handling and tree-size on harvester performance in small-diameter hardwood thinnings

Erber G., Holzleitner F., Kastner M., Stampfer K. (2015). Effect of multi-tree handling and tree-size on harvester performance in small-diameter hardwood thinnings. Silva Fennica vol. 50 no. 1 article id 1428. https://doi.org/10.14214/sf.1428

Highlights

- Harvesting with the accumulating energy wood head EF28 was studied under small tree dimension (8 dm3) in hardwood thinnings

- Reasonable productivity was achieved

- Maximum achieved cutting diameter in hornbeam stand was 23 cm and 15% lower than in softwood stands

- Head has potential under such conditions.

Abstract

Early thinnings are laborious and costly. Thus forest companies are searching for cost and time efficient ways to carry out this task. The study’s purpose was to determine the productivity of the EF28 accumulating energy wood harvesting head in harvesting small-diameter hornbeam (Carpinus betulus L.) undergrowth trees and evaluate the effect of its multi-tree handling (MTH) capacity on time consumption. The harvester was a wheeled, three-axle Komatsu 911. A time study of 7.1 hours on 19 plots, with a total area of 0.76 ha was conducted. On average, the harvested tree volume was 8 dm³ and the stand density was 2666 trees/ha. The productivity was modelled with MTH conduction, mean diameter at breast height and the number of trees handled per cycle as independent variables. On average, MTH took 27% longer per cycle, increased extracted volume per cycle by 33% and consequently increased productivity with 5.0%. In 71.9% of the cycles more than one tree was handled and if so, dimensions were smaller than in single-tree handling (5.8 cm vs. 12.0 cm). Maximum felling diameter of 23 cm was about 15% smaller than in softwood (according to the manufacturer’s specifications) and the driver didn’t exploit the EF28’s theoretical potential in terms of trees handled per cycle. It can be concluded that the head could significantly improve productivity in small-diameter wood procurement.

Keywords

productivity;

thinning;

energy wood;

motor-manual;

accumulating harvester head;

delimbing

-

Erber,

Addresses University of Natural Resources and Life Sciences Vienna, Department of Forest and Soil Sciences, Institute of Forest Engineering, Peter-Jordan Straße 82/3, A-1190 Vienna, Austria

E-mail

gernot.erber@boku.ac.at

- Holzleitner, Addresses University of Natural Resources and Life Sciences Vienna, Department of Forest and Soil Sciences, Institute of Forest Engineering, Peter-Jordan Straße 82/3, A-1190 Vienna, Austria E-mail franz.holzleitner@boku.ac.at

- Kastner, Addresses University of Natural Resources and Life Sciences Vienna, Department of Forest and Soil Sciences, Institute of Forest Engineering, Peter-Jordan Straße 82/3, A-1190 Vienna, Austria E-mail maximilian.kastner@boku.ac.at

- Stampfer, Addresses University of Natural Resources and Life Sciences Vienna, Department of Forest and Soil Sciences, Institute of Forest Engineering, Peter-Jordan Straße 82/3, A-1190 Vienna, Austria E-mail karl.stampfer@boku.ac.at

Received 29 July 2015 Accepted 10 November 2015 Published 20 November 2015

Views 106263

Available at https://doi.org/10.14214/sf.1428 | Download PDF

Supplementary Files

1 Introduction

In Austrian forests, the standing volume has increased steadily during the last 40 years (BMLFUW 2014). Nevertheless, due to changes in the social and economic framework, the number of people performing laborious early thinnings and undergrowth clearings has declined dramatically. Forest companies are thus searching for new ways to carry out this task efficiently, both in terms of timely execution and economic viability. The increased use of biomass for energy purposes during the last decade (BMLFUW, 2013) has offered new opportunities and boosted the interest in any additional material coming from the forest. Interest in small-diameter material from early thinning and undergrowth clearing operations is still rising. This material, which is usually comprised of wood with no industrial use, now offers new opportunities to be utilized as fuel wood. Low cutting productivity due to the small size of the removed trees is counted among the most serious problems in energy wood harvesting from early thinnings (Oikari et al. 2010). To carry out these operations motor-manually has simply become too costly, or the required number of workers is no longer available. Thus, at the moment, fully mechanized harvesting of small-diameter trees is the only feasible option. Purpose-built harvesting heads have been employed and have undergone constant development, especially in the Nordic countries (Laitila and Asikainen 2006; Eberhardinger 2007; Belbo 2010; Lehtimäki and Nurmi 2011; Rieppo and Mutikainen 2011; Di Fulvio and Bergström 2013; Laitila and Väätäinen 2013; Fernandez-Lacruz et al. 2013; Bergström and Di Fulvio 2014). By enabling efficient energy wood production, these types of heads are considered to offer an opportunity to counteract the decreasing frequency and postponement of early thinnings (Hakkila 2005; Heikkilä et al. 2007).

Energy wood harvesting heads have been studied extensively under Nordic conditions, mostly covering the species of pine (Pinus sylvestris L.), spruce (Picea abies (L.) H. Karst.) and birch (Betula spp.) (Laitila and Asikainen 2006; Eberhardinger 2007; Belbo 2010; Lehtimäki and Nurmi 2011; Rieppo and Mutikainen 2011; Di Fulvio and Bergström 2013; Laitila and Väätäinen 2013; Fernandez-Lacruz et al. 2013; Bergström and Di Fulvio 2014). Conversely, studies of broad leaf trees, especially hardwood species, have not been of major interest this far. Studies by Affenzeller and Stampfer (2007), Spinelli et al. (2007), Rottensteiner et al. (2008), and Schweier et al. (2015) at least partly cover energy wood head harvesting performance under hardwood conditions (beech (Fagus sylvatica L.), chestnut (Castanea spp.), hornbeam (Carpinus betulus L.), oak (Quercus spp.), and black locust (Robinia pseudoacacia L.)).

Currently, a large number of energy wood harvesting heads are available. They can be classified by their cutting elements, which include disk saws, saw bars and shear blades, the latter in either elliptical, guillotine or scissor-like configurations. Due to the absence of a conventional blade and a chain, guillotine cutting devices are advantageous in small-diameter operations, as small trees cannot slip between the bar and chain. Lately, harvesting heads equipped with disc-mounted saw chains have been introduced to counteract this effect (e.g., Bracke C16). A multi-tree handling capacity is a feature typical of up-to-date energy wood harvesting heads (Stampfer and Spinelli 2009). It increases productivity, especially in small tree dimensions (Lehtimäki and Nurmi 2011). Integrating feeding rollers and delimbing knives in recent types of energy wood harvesting heads have increased productivity in general and enabled the combined production of energy wood and industrial roundwood (Rottensteiner et al. 2008; Rieppo and Mutikainen 2011; Di Fulvio and Bergström 2013; Laitila and Väätäinen 2013; Bergström and Di Fulvio 2014). Before that, operators were only able to buck the bundles on the ground (Ovaskainen et al. 2008) or use the top-cutting method. The most sophisticated heads are equipped with a length measurement system (Rieppo and Mutikainen 2011; Laitila and Väätäinen 2013). Thus, specified log lengths and assortments for sawn timber can be produced, and biomass is more concentrated than via the single-tree method, which increases forwarding productivity (Väätäinen et al. 2006; Di Fulvio and Bergström 2013). Energy wood harvesting heads are usually applied either in a one-machine (harwarder) or two-machine (harvester and forwarder) configuration (Stampfer and Spinelli 2009) and can be mounted to a large range of other base machines, such as excavators, tractors and trucks (in roadside clearing operations). Harwarders should be employed on short forwarding distances and in small-dimensioned stands (Kärhä 2006), while the more common two-machine systems are more competitive on longer distances (Laitila 2008).

The Naarva EF28 head has been studied before under Nordic conditions by Rieppo and Mutikainen (2011), where the head was mounted on a wheeled ProSilva 910 harvester base machine and employed in a first thinning operation in a pine stand. If both energy wood and industrial roundwood (average tree volume of 79 dm³) were removed, an average productivity of 11.9 m³ per productive system hour (PSH0) was observed. If only energy wood was harvested (average tree volume of 82 dm³), productivity rose to 15.2 m³ per PSH0. Laitila and Väätäinen (2013) studied the same head mounted on a 15-ton New Holland Kobelco excavator in a first thinning operation of a pine stand. In this operation, both energy wood and industrial roundwood were produced. On average, a productivity of 12.8 m³ per PSH0 was achieved. In both studies, operators made use of the head’s multi-tree handling capacity extensively.

In Austrian hardwood studies, the average tree dimensions have ranged from 46 dm³ to 57 dm³ in volume and 9.23 cm to 9.36 cm in DBH (Affenzeller and Stampfer 2007; Rottensteiner et al. 2008). Further, DBH ranges of 6.5–10.2 cm (Spinelli et al. 2007) and 7–20 cm (Schweier et al. 2015) have been covered by other European studies. Head design is often dedicated to softwood conditions, which leads to a decrease of productivity and maximum felling diameter in hardwood, as reported by Rottensteiner et al. (2008).

Thus far, the EF 28 head has only been evaluated under typical Nordic conditions. There is no experience with harvesting hardwood species common in Central Europe or harvesting trees with volumes below 20 dm³. The objective of the study is to develop productivity models for the EF28 in small-diameter hardwood operations and to analyze the impact of the head’s multi-tree handling (MTH) capacity on the operation. The head’s performance shall be compared to motor-manual work in terms of cost and time consumption.

2 Material and methods

2.1 Study area and stand description

The study site was located in eastern Austria at Moschendorf (47°02´N, 16°27´E), in the south of the Burgenland province, and owned by the Austrian Federal Forests. The terrain was flat and without major obstacles. Due to the stagnogley soil, wet spots occurred here and there but did not hinder soil trafficability. The three studied mature stands, each separated from one another by younger stands, were composed of broadleaf (Fagus sylvatica, Quercus ssp., Carpinus betulus, Tilia cordata Mill. and Castanea sativa Mill.) and coniferous (Pinus sylvestris, Larix decidua Mill. and Picea abies) species. The dominating undergrowth species, scheduled for removal, was hornbeam (Carpinus betulus). The mean undergrowth diameter at breast height (DBH, basal area weighted) was 4.0 cm. The minimum DBH was 1.0 cm, the maximum diameter was 23.0 cm, and the respective heights were 3.8 m and 25.9 m. The mean undergrowth basal area was 262.0 m² ha–1. The mature stand’s basal area was not investigated.

2.2 Studied machinery

For the harvesting operation, a Naarva EF 28, an accumulating energy wood harvesting head (Supplementary file 1), manufactured by Outokummun Metalli Oy / Pentin Paja Oy, with accumulating arms, delimbing knives, and guillotine cutting (Suppl. file 2), as well as driven feed rollers, was employed. The head is designed for multi-tree felling and delimbing of wood from first thinnings for pulp and energy purposes. Length measurement to produce assortments in a cut-to-length manner is solved via a sensor in the feeding rollers. The harvester head weighs 700 kg, and its maximum cutting diameter is 28 cm. In the cutting position, the head’s height is 116 cm, and the maximum grapple opening is 83 cm. Feeding can be carried out within a diameter range from 2 cm to 39 cm with a force of 13 kN and a speed of 4 m s–1. Cutting with the guillotine is done with a force of 240 kN, for which a hydraulic oil flow of 170 l min–1 at a pressure of 240 bars is required. The head can be attached to a variety of base machines, including standard harvesters, 14-tonne to 20-tonne excavators and harwarders. The EF28 can be controlled either by the harvester’s own control system or the Naarva-automatic radio control system (Naarva, 2015).

For the study, the head was attached to a three-axle Komatsu 911 (construction year: 2003) base machine. The maximum boom reach of the machine was 10 m, and its weight was 18 tonnes. Due to favorable terrain conditions, no chains or boogie bands had to be attached.

2.3 Silvicultural prescription and working procedure

At the study site, the dense hornbeam undergrowth should be removed to enable natural regeneration establishment. All mature trees, except manually felled mature hornbeam trees, remained standing. Thus, no fixed, straight skid trails could be assigned; however, the harvester had to move between the mature trees in as straight a manner as possible, always taking into account that the forwarder would have to take the same route afterwards. The undergrowth was removed on both sides of the skid trails, which were located approximately 20 m apart from each other. The trees were felled and accumulated by the head, which was then moved to the skid trail for processing. There, the bunched trees were delimbed and cut to length. Four to five meters long and piled along the skid trail, each pile represented two to three forwarders’ grapples in volume (Suppl. file 3). Tops were left on the skid trail for soil protection. The harvested material was intended to be chipped later and used for energy purposes.

2.4 Time study

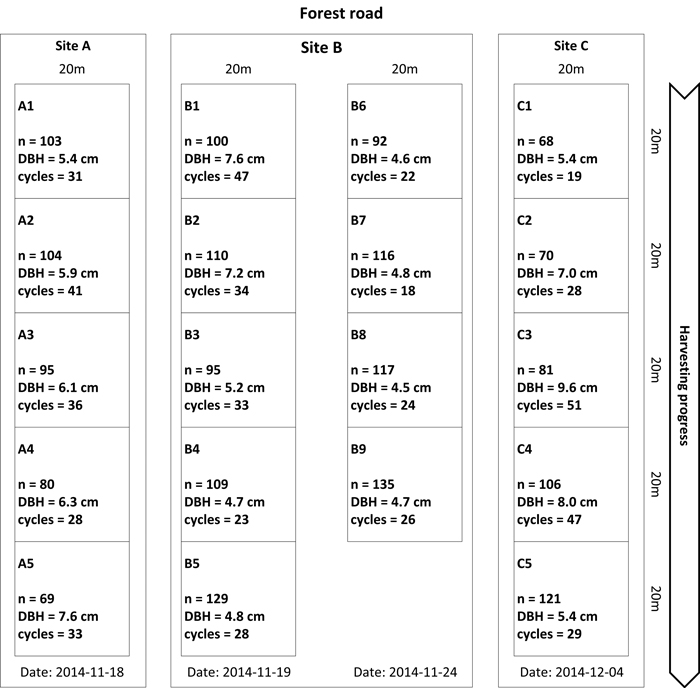

The time study took place on the 18th, 19th and 24th of November and on the 4th of December 2014 under natural light conditions during the daytime. The nineteen time study plots were each 20 m long and approximately 20 m wide (boom reach). The plot area totaled 0.76 ha. Plot boundaries were marked by colored ribbons strapped around the peripheral trees. Within each plot, diameters at breast height (DBH) were measured, recorded and marked on the stem using a pre-defined color and number code (1-cm steps; code for below 10 cm, and figures for larger diameters), facing the estimated location of the skid trail (Suppl. file 4). Thus, the diameter could be allocated exactly during the time study. The nineteen plots were located on four different skid trails in the three different stands (A, B and C) (Fig. 1).

Fig. 1. Study layout of the EF28 time study. Nineteen 400 m² plots were situated in three different stands (A, B and C). The direction of harvesting progress is displayed on the right. Plot information includes the number (n) of trees harvested per plot, the mean diameter at breast height per plot (DBH) and the number of crane cycles required for finishing this plot (cycles).

The machine operator was used to run harvesters and forwarders and had more than one month of work experience with the EF28 head in operations which differed from the study in terms of species (beech with a share of birch) and slope (20%).

The time study was carried out manually on a handheld computer (Algiz 7) and additionally recorded with an onboard video documentation device (Suppl. file 5). Thus, accurate repeatability of all time study activities and especially detailed post-processing of all recorded data is guaranteed. Video data was used for error correction, and at site B, plots 6 to 9, the time study was carried out based solely on the captured video material. The working time was recorded, employing both the continuous timing and snap back timing methods, because the software offers both options in one.

Effective working time phases were defined and priorities assigned. If two time phases overlapped (e.g., moving and felling), the activity with the higher priority (1: highest; 2: lowest) was recorded.

The following effective working time phases were defined and recorded:

Moving – begins when the harvester is moving forward or backward and ends when it stops to perform another activity. Moving only includes moving from one work location to the next without any felling or processing activity. Priority: 2

Felling – starts when the head is tilted into the upright position for felling and ends when the head is tilted into the horizontal position for processing. Priority: 1

Processing – starts when the head is tilted into the horizontal position for processing and ends when the head is tilted into the upright position for felling. Priority: 1

Delay – time not related to effective work (e.g., breaks, repairs, etc.).

In total, 598 working cycles were recorded during 7.1 h of time study. Further, the use of the MTH capacity (more than one tree handled per cycle) was recorded for each cycle.

2.5 Estimation of the harvested volume

A height curve was derived from 112 randomly selected tree’s DBH and height data covering the entire DBH range of the study site. Then, for each tree, the dry mass was estimated according to the Sterba and Nachtmann (2006) method for coppice species in eastern Austria. These functions estimate the dry matter of a tree based on its DBH and height. Time study plot’s average harvesting intensity ranged from 1,900 to 3,375 stems ha–1, and the harvested dry mass ranged from 14.2 tonnes ha–1 to 34.7 tonnes ha–1. In total, 2.031 stems with a total dry mass of 13.6 tonnes were harvested (Fig. 1). The mean dry mass per stem was 6.7 kg. At an average dry density of 820 kg m-³ for hornbeam (Austrian Energy Agency 2009), the mean stem volume was thus 8.2 dm³. The moisture content of 12 wood disks was assessed in accordance with the European standard CEN/TS 14774-2. According to the laboratory, the fresh moisture content varied between 35.9% to 45.9% with a mean moisture content of 41.5%.

2.6 Time consumption analysis

The recorded cycle-wise study data was combined with the tree volumes in a data matrix. All analyses were carried out with the statistical software R (R Core Team 2014). The productivity was calculated as dry matter tonnes per hour of productive work time (t PSH0–1) excluding delay time. The time consumption per unit of output (PSH0 t–1) of the main work elements was formulated through the application of regression analysis, where the mean DBH (DBHmean), the number of trees handled per cycle and the occurrence of MTH were included in statistical models. Two variates were calculated. While the first one comprised three separate models (one for the time consumption of each process), the second one estimated the overall time consumption. T- and F-tests were used to determine differences in the means and variances between MTH and single-tree handling (STH) parameters.

2.7 MTH impact analysis

In addition to the analyses mentioned above, the utilization rate of the MTH capacity in terms of physical limits of the head was studied. This regards the relation between the number of trees with a given DBHmean that have actually been fit into the grapple and how many trees could be fit into the grapple theoretically. For this analysis, the circular area of the thickest tree that could be handled during the studied operation was calculated. Then, for each cycle, the theoretical number of circles with the mean cycle’s DBH that could be fitted within this area was determined as shown by Friedman (2014). Subsequently, the number of trees handled in the observation was compared to the number in the theoretical calculation, and the capacity utilization in percent was calculated as the relation between reality and theory. As there were three options available to determine the utilization rate of the MTH capacity in terms of physical limits of the head, a reasonable reference limit first had to be selected. According to the manufacturer, the head’s maximum feeding diameter is 39 cm and its maximum felling diameter is 28 cm. For the analysis, the maximum achieved cutting diameter was used as a reference limit. Then, the maximum number of equally large circles that could be fit into a circle with the reference limit diameter was calculated for different numbers of trees. For example, for three trees, the maximum DBHmean per cycle was 10.7 cm, and for five it was 8.5 cm. This number was compared to the minimum, average and maximum DBHmean per cycle for each recorded number of trees.

Lastly, the difference in time consumption and cost between a motor-manual and mechanized conduction of the studied operation was calculated. For these calculations, the following assumptions were made: one ha should be cleared from the undergrowth, and the material should be piled along the skidding trail for later forwarder extraction. According to Österreichischer Agrarverlag (2014), 150 PMH15 (productive man hours including delays up to 15 min) have to be estimated for a motor-manual clearing of one ha of operation area, and an additional 100 PMH15 are necessary to manually concentrate the material at the skid trail. While the estimated rate for the motor-manual work was 35 € per PMH15, it was 130 € per hour for the harvester equipped with the EF28.

2.8 Valid range of the models

Models’ valid range for any further use depends on their creation circumstances and should be limited by their 5% and 95% quantile. The developed models should only be used under conditions similar to the study (mean stand DBH between 3.2 cm and 15.0 cm and 1 to 8 trees harvested per cycle).

3 Results

3.1 Time studies

While moving accounted for only 7.1% of the total effective working time, the proportions of cutting and processing were 49.7% and 43.2%, respectively. The mean cycle duration was 0.688 ± 0.292 min. The mean time consumption per plot was 21.650 ± 4.750 min. Delay time accounted for only 3.2% of the total recorded time. Even though the time study trials were rather short, the fast cycle times allowed the recording of 90 to 174 cycles per skidding trail.

3.2 Degree of MTH

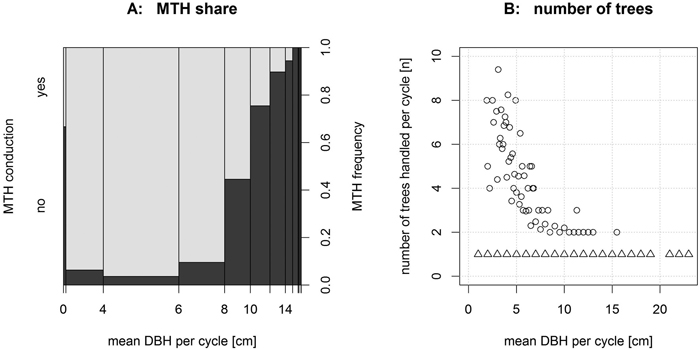

MTH was performed in 71.9% of the cycles; during the rest, only one tree was handled per cycle. The percentage of MTH operations decreased with increasing DBHmean per cycle. The share of MTH operations was more than 90% for DBHmean below 8 cm. From this point on, the share steadily dropped with increasing DBHmean (Fig. 2).

Fig. 2. A: The total share of multi-tree handling operations (MTH) (light grey) decreases with increasing DBHmean of trees harvested per cycle. B: Consequently, the number of trees (circle shaped symbols) handled per cycle decreases with increasing DBH. For a DBHmean of more than 16 cm, only single-tree handling operations (triangle shaped symbols) were recorded.

While the overall average number of trees handled per cycle was 3.2, the number rose to an average of 4.0 during MTH only (Fig. 3). The maximum number of trees handled per cycle was 13, which was achieved three times. STH operations were recorded for each diameter class. During MTH operations, DBHmean ranged from 1.9 cm to 15.5 cm, and between 0.008 t and 0.065 t of dry matter was harvested per cycle (Fig. 2).

Fig. 3. Effect (yes = multi-tree handling conducted, no = single-tree handling conducted) of multi-tree handling on the operation’s parameters.

The DBHmean per cycle during MTH was significantly (p-value ≤ 2×10–16) smaller (5.8 cm) than the DBHmean per cycle during STH (11.9 cm). Except for a small number of cases, the minimum DBHmean per cycle was larger than 3.0 cm. The maximum DBH harvested (as a single tree) was 23.0 cm (Suppl. file 6). If an additional centimeter in diameter at the cut is taken into account, approximately 85.7% of the maximum softwood felling diameter (according to the manufacturer’s specifications) was achieved. The thickest tree in a multi-tree operation had a DBH of 18.0 cm and was handled together with a 3.0-cm and a 2.0-cm tree. The smallest DBHmean in a multi-tree operation was 1.9 cm.

On average, the dry matter sum harvested per cycle was significantly (p-value = 4.3×10–2) larger when carrying out MTH operations (0.028 ± 0.010 t vs. 0.021 ± 0.012 t), while the maximum dry matter sum harvested during MTH (0.065 t) was slightly larger than the maximum dry matter sum harvested during STH (0.064 t). The minimum dry matter sums per cycle were 0.008 t and 0.002 t, respectively (Fig. 3).

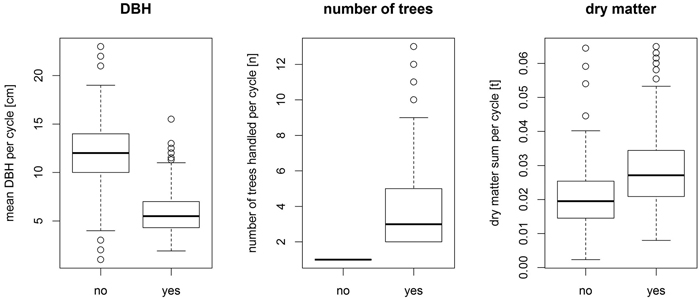

Because moving of the machine frequently occurred in conjunction with the felling process, the impact of multi-tree operations on moving time consumption per cycle cannot be adequately determined. If MTH was performed, felling took significantly (p-value = 2.2×10–16) more time (0.385 ± 0.204 min vs. 0.233 ± 0.119 min) per cycle. The processing time per cycle did not differ significantly (p-value = 0.828) between MTH and STH (0.296 ± 0.135 min vs. 0.300 ± 0.022 min). The overall time consumption (moving, felling and processing) differed significantly per cycle (p-value = 1.1×10–7; 0.732 ± 0.278 min vs. 0.575 ± 0.298 min) between MTH and STH (Fig. 4).

Fig. 4. Effect of multi-tree handling (yes = multi-tree handling conducted, no = single-tree handling conducted) on the time consumption (top) and efficiency (bottom) of the main work elements and in total.

The felling efficiency in MTH (0.23 ± 0.10 PSH0 t–1) was slightly, but not significantly (p-value = 0.542), lower than in STH (0.24 PSH0 t–1 ± 0.20 PSH0 t–1), while the processing efficiency was significantly higher (p-value = 1.1×10–9; 0.19 ± 0.09 PSH0 t–1 vs. 0.26 ± 0.14 PSH0 t–1). The total average efficiency was significantly higher (p-value = 2.2×10–16; 0.45 ± 0.15 PSH0 t–1 vs. 0.55 ± 0.32 PSH0 t–1) in multi-tree operations. Generally, the MTH efficiency varied significantly lesser than the STH efficiency (p-value = 2.2×10–16; Fig. 4).

Productivity differed only slightly and not significantly (p-value = 0.200; 2.43 ± 0.81 t PSH0–1 vs. 2.32 ± 1.05 t PSH0–1) between MTH and STH. The average total cycle volume during MTH was 34 dm³, while it was 26 dm³ during STH.

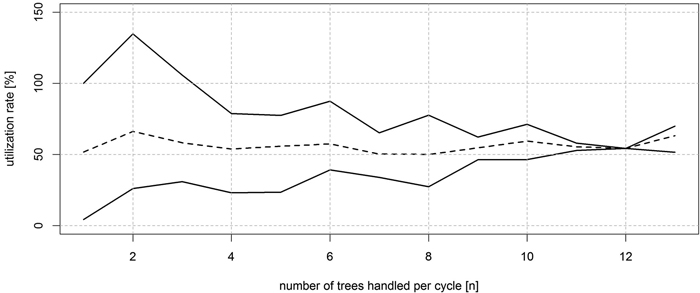

The operator tried to fell larger diameter trees but could not manage to fell trees with a diameter larger than 23 cm. Thus, this diameter was selected as the reference limit for the MTH utilization rate. It showed that, on average, 56.2% of the theoretically available circular area capacity was utilized. As expected, the smallest and largest minimum utilization rates were recorded for processing one tree, each on the opposite end of the diameter distribution (Fig. 5). For small trees of 2 cm in mean diameter, more than the theoretical capacity could be utilized.

Fig. 5. Utilization rate of the theoretical physical multi-tree handling capacity, which is expressed by the relation of the cumulated circular area of the tree’s diameter handled during a cycle to the theoretical maximum circular area that can be handled by the head. Solid lines represent the upper (top) and lower (bottom) limit, while average utilization rate is displayed as dashed line.

3.3 Modeling of time consumption

On a cycle level, time consumption for moving (Eq. 1) could only be related to the conduction of multiple tree handling (MTH), but not the stand density (R²adj = 0.007; p-value = 2.1×10–2). No statistically significant difference could be found between STH and MTH for the time required for moving. For felling time consumption (Eq. 2; R²adj = 0.49; p-value = <2×10–16), significant impacts of the DBHmean (p-value = <2×10–16), the number of trees (ntrees) (p-value = <2×10–16) handled within the cycle and the conduction of MTH (0 = no MTH; 1 = MTH) (p-value = <2×10–16) were detected. Processing time consumption (Eq. 3; R²adj = 0.21; p-value = <2.0×10–16) was influenced by both DBHmean (p-value = 6.2×10–11) and the number of handled trees (p-value = <2.0×10–16), as well as the conduction of MTH (p-value = <4.8×10–5). The sum of these three equations’ results represents the total time consumption (cumulative processes’ time consumption).

As an alternative, a second one-equation model for the total time consumption was calculated (R²adj = 0.42; p-value = <2×10–16). Again, the time consumption could be explained by the DBHmean (p-value = <2×10–16), the number of handled trees (p-value = <2×10–16) and the conduction of MTH (p-value = <2×10–16) (Eq. 4).

Both variates were checked for a possible inter-correlation of MTH conduction and the number of trees handled per cycle, but none of these was found to be significant.

To enhance the estimation of the number of trees handled per cycle, a model (Eq. 5; R²adj = 0.42; p-value = <2×10–16) with the DBHmean (p-value = <2×10–16) as the explanatory variable was developed. All reported correlations were significant at a significance level of 5%.

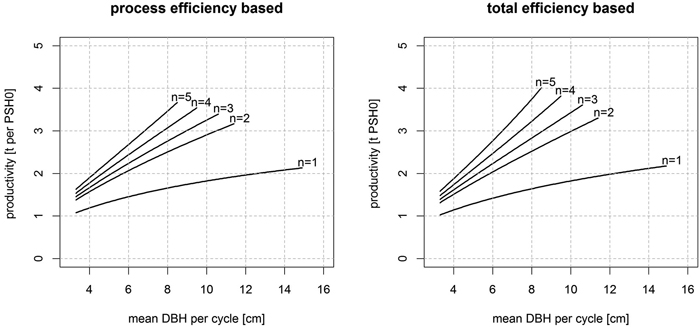

Overall productivity was either estimated as displayed in Eq. 6 (based on cumulative processes’ time consumption; Prodproc time) or Eq. 7 (based on total time consumption; Prodtot time). The mean deviances of the estimated productivity from the observation were –0.18 ± 0.74 t PSH0–1 and –0.16 ± 0.75 t PSH0–1, respectively.

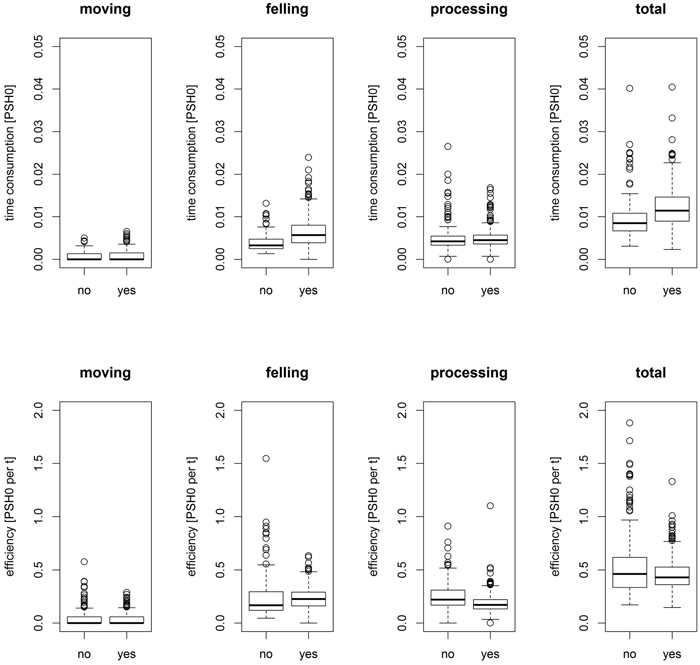

In Fig. 6, model estimates are displayed within the models’ valid range and truncated either where the valid range of the model was exceeded or where the cumulated circular area at the cycle’s DBHmean exceeded the theoretical physical limit of the head’s processing capacity. If five trees were harvested, the DBHmean of these trees could not exceed 8 cm, while with two trees the limit was 11 cm DBHmean.

Fig. 6: The productivity of the EF28 for different numbers (n) of trees per cycle and mean diameter at breast height (DBH) per cycle.

where

Effmoving = Time consumption for moving per unit of output

Efffelling = Time consumption for felling per unit of output

Effprocessing = Time consumption for processing per unit of output

Efftot = Total time consumption per unit of output

ntrees = Number of trees harvested per cycle

Prodproc time = Productivity in units of output per time consumption based on process efficiency

Prodtot time = Productivity in units of output per time consumption based on total efficiency

MTH = Conduction of multi tree handling, where 1 = multi-tree handling conducted and 0= single-tree handling conducted

DBHmean = Harvested tree’s mean diameter at breast height

3.4 Productivity

The average productivity was 2.40 ± 0.88 t PSH0–1 (2.93 m³ at an average dry density of 820 kg m–³ for hornbeam) or 277 trees. The minimum and maximum productivity were 0.53 t PSH0–1 and 6.84 t PSH0–1, respectively. On a plot level, the mean productivity ranged from 2.07 t PSH0–1 (2.52 m³ PSH0–1) to 2.61 t PSH0–1 (3.18 m³ PSH0–1). The number of trees harvested per plot ranged from 68 to 135 and averaged 100.

3.5 Cost

With a harvester equipped with the EF28, 11.8 PSH15 (9.1 PSH0 per ha converted to PSH15 by a factor of 1.3; assumption based on previous harvester studies, e.g., Stampfer (2001)) are necessary to clear one ha and concentrate the material at the skidding trail. Thus, the total costs per ha were 8750 € for the motor-manual and 1534 € for the harvester work.

4 Discussion

The purpose of this study was to evaluate the performance of the Naarva EF28 accumulating energy wood harvesting head mounted on a harvester in small-diameter hardwood harvesting operation and to assess the impact of the head’s MTH capacity. The results show that a machine equipped with the EF28 is able to harvest small-diameter hardwood efficiently, both in terms of productivity and costs.

The head’s maximum felling diameter of 28 cm (according to the manufacturer’s specifications for softwood) was never reached. The operator tried several times to fell trees of that dimension but never succeeded. Even when harvesting trees of approximately 20 cm DBH, the operator had to cut the trees repeatedly from different directions. Thus, it can be concluded that the head’s maximum felling diameter in hardwood is at least 15% smaller than in softwood (the manufacturer recommends a reduction of 30% for hardwood species). These findings correspond with those of Spinelli et al. (2007), Rottensteiner et al. (2008) and Schweier et al. (2015). Lastly, it has to be taken into account that hornbeam is one of the hardest hardwoods in Central Europe.

The EF28’s capability to produce delimbed, cut-to-length multi-stem piles is an advantage in terms of forwarding productivity. Biomass is concentrated in forwarding – ready piles at the skid trail, and thus forwarding can be carried out much faster (Väätäinen et al. 2006; Spinelli and Magagnotti 2010) and, due to delimbing, with increased bulk density compared to whole trees (Heikkilä et al. 2006; Bergström et al. 2010; Laitila and Väätäinen 2012). In former motor-manual operations, the material would have either been scattered all across the stand or would have been concentrated by hand at the strip road. While, in the first case, it would take more time for the forwarder to collect the material, in the second case, it would take more time to concentrate the material at the skid trail by hand. In both cases, whole trees of various lengths would have to be forwarded, which would have been the same with felling-only heads. Single-grip harvesting heads would also be able to concentrate the material at the skid trail, but, without the accumulating arms, trees would have to be processed one at a time, which would most likely result in lower productivity during harvesting. Bergström and Di Fulvio (2014) note that, by delimbing and bucking, less biomass is extracted from the forest. In Austria, at least a significant share, especially in small branches, shall remain in the stand to prevent nutrient loss. In this respect, this decrease in extracted biomass is no point of concern.

The physical utilization rate of the MTH capacity is a difficult and insufficiently studied topic. The most difficult decision is which diameter to use for referencing. For this study, the maximum achieved cutting diameter was concluded to be the most reasonable, even though the theoretical capacity was exploited by more than 100% for trees of 2 cm in mean diameter. Here, compaction could play a role. A probable reason for regularly not exploiting the theoretical potential in full is that, firstly, there are not necessarily enough trees within the boom’s reach to fill the head during one cycle. Belbo (2011) observed a larger degree of accumulation in a stand of larger density. Further, the boom movement could have been hindered by the remaining mature stand, thus inducing the operator to complete a cycle, move the machine to a new position and start a new cycle, even though the capacity of the head was not exploited fully. In classic thinning operations, methods such as “boom-corridor-thinning” could counteract this effect (Bergström et al. 2010; Sängstuvall et al. 2012). Secondly, trees are usually not perfectly circular-shaped and therefore do not fit together as perfect circles would. Thirdly, especially small trees can be bent and bulky and thus make full utilization impossible.

Contrary to Di Fulvio and Bergström (2013) and Laitila and Väätäinen (2013), no effect of the stand density on the productivity could be observed. Because the models in the present study were calculated on a cycle level, it is not likely that this parameter had an effect. For comparison reasons, models were also calculated on a plot level. Again, no significant effect of stand density could be observed. Apart from that, the explaining variable set is in line with the sets of Bergström and Di Fulvio (2014) and Laitila and Väätäinen (2013) and very similar to that of Spinelli et al. (2007).

The observed average productivity (2.9 m³ PSH0–1) is significantly lower in terms of volume than in the EF28 studies by Rieppo and Mutikainen (2011) (11.9 m³ PSH0–1) and Laitila and Väätäinen (2013) (15.2 m³ PSH0–1). If the functions of the later study are used to calculate the expected productivity, the result is 3.8 m³ PSH0–1. In this respect, one has to take into account that these functions were developed for a range of 23–89 dm³ in average tree volume. Reverse calculation of the present study’s functions was not possible, since Laitila and Väätäinen (2013) do not give any figures for the average diameter of the removed trees.

Spinelli et al. (2007) carried out a study on hornbeam coppice harvesting with Timberjack 720 and 730 shear heads in France. With an average tree volume of 24 dm³, the mean productivity was 4.1 t (green) PSH0–1. If the present study’s data is put into this study’s functions, the estimated productivity is 2.98 t (green) PSH0–1 and, at the observed moisture content of 41.5%, 1.74 t PSH0–1 in dry matter. Thus, harvesting with the EF28 was more productive than it would have been with the equipment in the cited study. Differently from the present study, no bucking, unless trees were taller than 10 m, was conducted.

Results presented in this study are based on the output of one harvester operator. If the same machine is operated by another operator, results may differ. Differences could be explained by human factors (driver’s motoric skills, work planning and decision-making process) during the operation (Ovaskainen et al. 2004). Purfürst (2009) concluded that under favorable conditions and in easy terrain the effect of the operator on the overall performance amounts to 37%. The wide range in observed productivity of 0.53 t PSH0–1 to 6.84 t PSH0–1 further indicates a large potential for variation. Due to the fact that the time study has been conducted during several days and at different daytimes, the effect of daily form is incorporated to at least some degree. On the other hand, the operator had only some weeks of experience with the head. Thus his performance would likely improve if he gained more experience with the head. However, steering and handling procedures of the head didn’t differ from a normal harvesting head to a large degree.

In comparison with STH, the average volume handled per cycle was 30% larger in MTH, but the increased time consumption (+30%) during MTH compensated for this effect. The average time per tree was 59% shorter for MTH, which corresponds to the difference in average tree volume (62%). If similar tree dimensions are compared, MTH had a significant effect on the average productivity (c.f. Belbo 2011). For example, for a DBHmean of 8 cm, the productivity rose from 1.7 t PSH0–1 (one tree) to 2.5 t PSH0–1 (two trees; +50%). A further increase in the number of trees resulted in a productivity of 3.5 t PSH0–1 (five trees; +110%). Ovaskainen et al. (2008) and Lehtimäki and Nurmi (2011) investigated a productivity increase of up to 35% for MTH. MTH frequency on a plot level ranged between 47% and 95%, which corresponds with the findings of Ovaskainen et al. (2008).

From a cost point of view, the work with the EF28 clearly outperformed the motor-manual work. If the hourly rate for the motor-manual work had been 20 €, it would still have been more than three times the cost of the mechanized work. Even if one included a reduction in stand value due to repeated runs of heavy machines on the same skid trails, it is not likely that the mechanized operation would end up more expensive. To the contrary, Schweier et al. 2015 indicated the positive effect of the mechanized harvesting of biomass on work safety compared to motor-manual operations. Nevertheless, it must be noted that this comparison is a hypothetical desk comparison and therefore only a general approximation.

Detailed process analysis using on-board video capturing offered the opportunity to repeat faulty parts of the time study recordings in the field and to carry out a part of the process analysis based solely on the captured video material. This procedure enhances transparency in work studies in general, as anyone who has doubts about the results can repeat the analysis based on this material.

Nevertheless, the study’s results could have been enhanced by some improvements in the study design. Firstly, the test was limited to a clearing operation, which is similar to a thinning operation in tree properties but not in working method. Even though the remaining mature stand made it necessary to work similarly to how one would in a thinning operation, a much smaller number of hindering trees was present. Therefore, damage to the remaining stand could not be assessed. Due to the fact that the total duration of the time studies was rather short (between 1.2 h and 2.0 h), delay time surely was underestimated. Long-term studies point at an incidence of delays between 20% and 70%, with an average of 30% (Spinelli and Visser 2008). At least two times during the operation, but not during the time studies, work was delayed by several hours for repairs. Longer time study duration, either based on machine data or long-term data recorded by the entrepreneur, could enhance the results in determining the delay share. Unfortunately, the subsequent forwarding operation could not be studied, as the stand remained impassable due to a high groundwater level after winter. This would have been of interest in terms of probably increased productivity due to better material concentration. It could have further been determined how much of the harvested material remains in the stand after extraction.

In line with the results of Ovaskainen et al. (2008), Rottensteiner et al. (2008), Laitila et al. (2010), and Lehtimäki and Nurmi (2011), the MTH capacity of the EF28 can be concluded to significantly improve the productivity of operations in small-diameter hardwood stands. Compared to former motor-manual operations, the EF28 and any similar head are particularly advantageous in terms of operation cost, forwarding enhancement and work safety. In terms of productivity, it can be assumed that accumulating and feed-roller-equipped harvesting heads are more productive than single-grip and felling-only harvesting heads (c.f. Laitila and Väätäinen 2013) and that forwarding operations are enhanced by concentrating the material at the skid road. Therefore, this type of head can be a promising answer to the issues in small-diameter wood procurement reported by Oikari et al. (2010) and a feasible option for economically viable operations in small-diameter hardwood operations in Central Europe.

Acknowledgments

This work was funded by the INFRES- project (European Union Seventh Framework Programme (FP7/2012–2015) under grant agreement n°311881). The authors want to thank the Austrian Federal Forests for providing the studied operation and the entrepreneur Holz Schwarz GmbH for supporting the study.

References

Affenzeller G., Stampfer K. (2007). Energieholzbereitstellung mit Traktor und Krananhänger mit Fallbeilklingenaggregat. [Tractor and trailer based fuel wood harvesting with a guillotine equipped fuel wood harvesting head]. Project report - Institut für Forsttechnik (FT), BOKU-Universität für Bodenkultur. 33 p. [In German].

Austrian Energy Agency (2009). Empfohlene Umrechnungsfaktoren für Energieholzsortimente bei Holz- bzw. Energiebilanzberechnungen. [Recommended conversion factors for energy wood assortments for wood- and energy balance calculations]. http://www.klimaaktiv.at/erneuerbare/energieholz/werkzeuge-und-hilfsmittel/umrechnungsfaktoren.html. [In German]. [Cited 6th July 2015].

Austrian Federal Ministry of Agriculture, Forestry, Environment and Water Management (BMLFUW) (2014). Österreichischer Waldbericht 2015. [Austrian forest report 2015]. http://www.bmlfuw.gv.at/dms/lmat/publikationen/forst/waldbericht/waldbericht2015/Waldbericht-2015/Waldbericht%202015.pdf?1=1. [In German]. [Cited 30th June 2015].

Austrian Federal Ministry of Agriculture, Forestry, Environment and Water Management (BMLFUW) (2014). Datensammlung zum Österreichischen Waldbericht 2015. [Austrian forest report 2015 data collection]. http://www.bmlfuw.gv.at/dms/lmat/forst/oesterreich-wald/waldzustand/datensammlung2015/Datensammlung_Waldbericht-2015_Uploadend/Datensammlung_Waldbericht%202015_Uploadend.pdf?1=1. [In German]. [Cited 30th June 2015].

Belbo H. (2010). Comparison of two working methods for small tree harvesting with a multi tree felling head mounted on farm tractor. Silva Fennica 44(3): 453–464. http://dx.doi.org/10.14214/sf.1280.

Belbo H. (2011). A simulation approach to determine the potential efficiency in multi-tree felling and processing. Proceedings of the 44th international symposium on forestry mechanisation: pushing the boundaries with research and innovation in forest engineering, October 9–13, 2011, Graz, Austria.

Bergström D., Di Fulvio F. (2014). Evaluation of a novel prototype harvester head in early fuel-wood thinnings. International Journal of Forest Engineering 25(2): 156–170. http://dx.doi.org/10.1080/14942119.2014.945697.

Bergström D., Bergsten U., Nordfjell T. (2010). Comparison of boom-corridor thinning and thinning from below harvesting methods in young dense Scots pine stands. Silva Fennica 44(4): 669–679. http://dx.doi.org/10.14214/sf.134.

Eberhardinger A. (2007). Schwarze Zahlen in der Schwachholzernte? [Black figures in small diameter wood harvesting?] Forst & Technik 5: 2–6. [In German].

Fernandez-Lacruz R., Di Fulvio F., Bergström D. (2013). Productivity and profitability of harvesting power line corridors for bioenergy. Silva Fennica 47(1) article 904. http://dx.doi.org/10.14214/sf.904.

Di Fulvio F., Bergström D. (2013). Analyses of a single-machine system for harvesting pulpwood and/or energy-wood in early thinnings. International Journal of Forest Engineering 24(1). http://dx.doi.org/10.1080/14942119.2013.798935.

Friedman E. (2014). Circles in circles. http://www2.stetson.edu/~efriedma/cirincir/. [Cited 6 Jul 2015].

Hakkila P. (2005). Fuel from early thinnings. International Journal of Forest Engineering 16(1): 11–14.

Heikilä J., Laitila J., Tanttu V., Siren M., Asikainen A. (2006). Harvesting alternatives and cost factors of delimbed energy wood. Forestry studies / Metsanduslikud Uurimused 45: 49–56.

Heikilä J., Siren M., Ärjälä J.O. (2007). Management alternatives of energywood thinning stands. Biomass and Bioenergy 31(5): 255–266. http://dx.doi.org/10.1016/j.biombioe.2007.01.013.

Kärhä K. (2006). Whole-tree harvesting in young stands in Finland. Forestry Studies / Metsanduslikud Uurimused 45: 118–134.

Laitila J. (2008). Harvesting technology and the cost of fuel chips from early thinnings. Silva Fennica 42(2): 267–283. http://dx.doi.org/10.14214/sf.256.

Laitila J., Asikainen A. (2006). Energy wood logging from early thinnings by harwarder method. Baltic Forestry 12(1): 94–102.

Laitila J., Väätäinen K. (2012). Truck transportation and chipping productivity of whole trees and delimbed energy wood in Finland. Croatian Journal of Forest Engineering 33(2): 199–210.

Laitila J., Väätäinen K. (2013). The cutting productivity of the excavator-based harvester in integrated harvesting of pulpwood and energy wood. Baltic Forestry 19(2): 289–300.

Lehtimäki J., Nurmi J. (2011). Energy wood harvesting productivity of three harvesting methods in first thinning of scots pine (Pinus sylvestris L.). Biomass and Bioenergy 35(8): 3383–3388. http://dx.doi.org/10.1016/j.biombioe.2010.09.012.

Naarva (2015). Technical specifications of the Naarva EF28 head. http://www.pentinpaja.fi/app/product/view/-/id/2/cat_id/7/set_language/en.

Oikari M., Kärhä K., Palander T., Pajuoja H., Ovaskainen H. (2010). Analyzing the views of wood harvesting professionals related to the approaches for increasing the cost-efficiency of wood harvesting from young stands. Silva Fennica 44(3): 481–495. http://dx.doi.org/10.14214/sf.144.

Österreichischer Agrarverlag (2014). Forst Jahrbuch 2014. [Forestry yearbook 2014]. Österreichischer Agrarverlag, Vienna, Austria. 342 p. [In German].

Ovaskainen H., Uusitalo J., Väätäinen K. (2004). Characteristics and significance of a harvester operators’ working technique in thinnings. International Journal of Forest Engineering 15(2): 67–77.

Ovaskainen H., Palander T., Jauhiainen M., Lehtimäki J., Tikkanen L., Nurmi J. (2008). Productivity of energywood harvesting chain in different stand conditions of early thinnings. Baltic Forestry 14(2): 149–154.

Purfürst F.T. (2009). Der Einfluss des Menschen auf die Leistung von Harvestersystemen. [The operator’s influence on harvester productivity]. PhD-thesis. Institut für Forstnutzung und Forsttechnik, Technische Universität Dresden, Germany. 307 p.

R Core Team (2014). R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. http://www.R-project.org/.

Rieppo K., Mutikainen A. (2011). Naarva EF28 integroidussa ja energiapuun hakkuussa. TTS:n tiedote: metsätyö, -energia ja yrittäjyys 8/2011 (753) 6 p. [In Finnish].

Rottensteiner C., Affenzeller G., Stampfer K. (2008). Evaluation of the feller-buncher moipu 400E for energy wood harvesting. Croatian Journal of Forest Engineering 29(2): 117–128.

Sängstuvall L., Bergström D., Lämås T., Nordfjell T. (2012). Simulation of harvester productivity in selective and boom-corridor thinning of young forests. Scandinavian Journal of Forest Research, 27(1): 56–73. http://dx.doi.org/10.1080/02827581.2011.628335.

Schweier J., Spinelli R., Magagnotti N., Becker G. (2015). Mechanized coppice harvesting with new small-scale feller-bunchers: results from harvesting trials with newly manufactured felling heads in Italy. Biomass and Bioenergy 72: 85–94. http://dx.doi.org/10.1016/j.biombioe.2014.11.013.

Spinelli R., Magagnotti N. (2010). Comparison of two harvesting systems for the production of forest biomass from the thinning of Picea abies plantations. Scandinavian Journal of Forest Research 25(1): 69–77. http://dx.doi.org/10.1080/02827580903505194.

Spinelli R., Visser R. (2008). Analyzing and estimating delays in harvester operations. International Journal of Forest Engineering 19(1): 36–41.

Spinelli R., Cuchet E., Roux P. (2007). A new feller-buncher for harvesting energy wood: Results from a European test programme. Biomass and Bioenergy 31(4): 205–210. http://dx.doi.org/10.1016/j.biombioe.2006.08.002.

Stampfer K., Spinelli R. (2009). Fäller-Bündler im Kommen. [Feller-Bunchers on the advance]. Wald und Holz 4: 32–34. [In German].

Stampfer K., Steinmüller T. (2001). A new approach to derive a productivity model for the harvester Valmet 911 Snake. In: Schiess & Krogstad (eds.). Proc., international mountain logging and 11th Pacific Northwest skyline symposium – a forest engineering odyssey. December 10–12, 2001, Seattle, Washington, USA. p. 254–262.

Sterba H., Nachtmann G. (2006). Biomassefunktionen für Ausschlagwaldbaumarten im Osten Österreichs. [Biomass functions for coppice forest tree species in eastern Austria]. In: Nagel J. (ed.). Sektion Ertragskunde: Beiträge zur Jahrestagung 2006, 29–31.05.2006, Staufen.Deutscher Verband forstlicher Forschungsanstalten, Göttingen. ISSN 1432-2609. p. 184–189. [In German].

Väätäinen K., Ala-Fossi A., Nuutinen Y., Röser D. (2006). The effect of single grip harvester’s log bunching on forwarder efficiency. Baltic Forestry 12(1): 64–69.

Total of 39 references.