Retrofitting urban areas with wood: the origin of new projects in an emerging business ecosystem

Viljanen A., Kurttila M., Toppinen A. (2024). Retrofitting urban areas with wood: the origin of new projects in an emerging business ecosystem. Silva Fennica vol. 58 no. 4 article id 23068. https://doi.org/10.14214/sf.23068

Highlights

- Decarbonizing building stock requires businesses to create new solutions for markets

- Wood-material based retrofits offer new possibilities but are yet rare in urban context

- The city-owned housing companies are found to be most aware of seizing opportunities of climate-benefits and facelifts in the less appealing suburban areas

- Actors use dynamic capabilities in niche-level projects, yet the reconfiguring stage of business models is not visible.

Abstract

Nurturing a low-carbon residential building stock requires businesses to create new solutions for markets. Wood material-based retrofits would be one solution but have remained rare in the urban context. Our study explores the structure and dynamics of an emerging business ecosystem (BE) of wooden retrofits in Finland. We study wooden retrofit projects, from the perspective of the initial steps of local-level development. By applying the concepts of BE and dynamic capabilities, we aim to shed light on the role of actors and their early-stage decision-making and use actor mapping and qualitative analysis of 27 thematic interviews with retrofit businesses and municipal actors. Results show that project initiation has relied on individual champions seizing opportunities as a main base in building dynamic capabilities. Builders and customers are key actors of wooden retrofit projects in local BEs in Finland. The identified actors are further involved with future plans for wooden retrofits, some with ambitious deep renovation with wood. Motivations for projects are driven from urban densification strategies, improvement of suburban neighborhood attractiveness and from the efficiency of space utilization. Results further elaborate a certain degree of difficulty in the early-stage decision-making. This study contributes to the scientific knowledge of both the BE and the dynamic capability perspective by exploring a path to material-driven sustainable construction in the Finnish context. We provide new information on this emerging retrofit construction business with potentially significant international implications if scaled up more widely.

Keywords

decision-making;

business ecosystem;

dynamic capabilities;

project initiation;

vertical building;

wooden retrofits

-

Viljanen,

University of Helsinki, Faculty of Agriculture and Forestry, Latokartanonkaari 7, 00014 Helsingin yliopisto, Finland

https://orcid.org/0000-0001-7166-8022

E-mail

anne.viljanen@helsinki.fi

https://orcid.org/0000-0001-7166-8022

E-mail

anne.viljanen@helsinki.fi

-

Kurttila,

Natural Resources Institute Finland (Luke), Research and Customer Relationships, Yliopistokatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0000-0001-5290-4771

E-mail

mikko.kurttila@luke.fi

https://orcid.org/0000-0001-5290-4771

E-mail

mikko.kurttila@luke.fi

-

Toppinen,

University of Helsinki, Faculty of Agriculture and Forestry, Latokartanonkaari 7, 00014 Helsingin yliopisto, Finland

https://orcid.org/0000-0003-0910-1505

E-mail

anne.toppinen@helsinki.fi

https://orcid.org/0000-0003-0910-1505

E-mail

anne.toppinen@helsinki.fi

Received 3 November 2023 Accepted 3 September 2024 Published 25 September 2024

Views 40531

Available at https://doi.org/10.14214/sf.23068 | Download PDF

Supplementary Files

1 Introduction

“Management must be entrepreneurial, sensing if not creating new opportunities before others do, and executing swiftly and expertly and collaboratively where the situation allows and requires.” (Teece 2009, xi)

The World Green Building Council (2021) is strongly fostering the decarbonization of the construction and building sector by 2050, including the transition of both operational and embodied carbon across the building life cycle (WorldGBC 2021). This is a significant undertaking, as the construction and building sector currently accounts for nearly 40% of energy- and process-related carbon dioxide emissions (GlobalABC et al. 2019). According to the estimate by WorldGBC (2021), over half of the carbon emissions of buildings constructed between 2020 and 2025 will stem from upfront emissions. Hence, there is a global need for new climate-smart building solutions, for example in the form of building retrofits (The White House 2021). In Europe, the estimated share of current buildings that will still be standing in 2050 is very high, 85–95% (EEA 2022). The European Commission (EC) supports a shift to more sustainable buildings with various initiatives suggested in the European Green Deal (EC 2019), the Circular Economy Action Plan (EC 2020a), and the Climate-Neutral Renovation Wave (EC 2020b). However, the building industry remains stagnant in its material use and is characterized by strong path-dependencies (Hurmekoski et al. 2015; Gosselin et al. 2017; Hemström et al. 2017; Toppinen et al. 2019a). Hence, there is a scope for building industry businesses to sense new business opportunities in decarbonization.

With continuing urbanization, urban residential construction is particularly in turmoil. Northern Europe is seeing a significant opportunity for implementing energy efficiency measures in the large body of suburban houses built during the 1960s and 1970s. Consequently, there is a call for comprehensive residential retrofits as novel business models, for example in energy efficiency-improving retrofits (Karvonen 2013; Brown 2018; Killip et al. 2020). In the emerging new solutions in a project-based building industry, focus is placed on the networks of organizational actors in a wider sense.

Wooden retrofits of multistory buildings are a rare phenomenon. In Finland, wood is being used or piloted in retrofits of existing multistory buildings mainly in two main ways, namely in the form of rooftop stackings of vertical buildings (Karjalainen et al. 2021; Viljanen et al. 2023) or in the form of facade replacements (Capener et al. 2014). Wooden retrofits of regular multistory buildings have been tested in recent years. For instance, wooden rooftop stackings have been studied and executed in the “Timber on top” -project in Sweden (Svensson 2022; Holström et al. 2024), while prefabricated wooden elements in insulating building facades have been piloted in Estonia, for instance (D’Oca et al. 2018).

Notably, concerning wooden retrofits of multistory buildings, the business logics has so far been neglected in research. For example, a meta-analysis of sustainable retrofits by Dauda and Ajayji (2022) shows that the majority of the analyzed articles focused on energy. Moreover, studies have shown that the perspective of retrofitting materials is considered less in the literature (Pomponi et al. 2017; Lima et al. 2020). In addition, social science studies of wooden retrofits in multistory buildings are rare, with the few exceptions including Karjalainen et al. (2021) and Pihelo et al. (2017, 2020). There are studies to draw from concerning the project-based dynamics of new residential wooden construction (Toppinen et al. 2019; Viholainen et al. 2021), but none that are connected to wooden retrofits of multistory buildings.

In this study, we explicitly connect the novel phenomenon of wooden retrofits in multistory buildings with the dynamic capabilities of companies at the project level. We apply the business ecosystem (BE) concept from Moore (1993), as means for analyzing the key actors in the wooden retrofits’ context. Specifically, we focus on how the project-based construction industry introduces this specific form of retrofits into their activities interrelated with other network participants. Pulkka et al. (2016) first established the applicability of the BE concept in the construction industry setting with positive impacts on value creation and capture for related business. To our knowledge, the linkage of BE to dynamic capabilities has not been studied earlier, with the exception of Stehn et al. (2021) and Holtström et al. (2024).

To fill this gap, our aim is to investigate wooden retrofits in residential multistory buildings in the Finnish context by posing the following research questions:

RQ1: Who are the key actors in the emerging project-based wooden retrofit business ecosystem?

RQ2: What kind of contextual and decision-making -related factors and dynamic capabilities can be identified among wooden retrofit projects?

2 Previous literature

Business ecosystems portray high order actor-networks reaching beyond the traditional ones. The main purposes are innovations and value created by the business ecosystem members, for instance producers, suppliers, customers, and financiers (Moore 1998, 2003, 2006; Aarikka-Stenroos and Ritala 2017). Drawing from complexity theory, systems theory, and evolutionary biology the business ecosystem highlights the complementary, dynamic, and interrelated nature of the actors within (Iansiti and Levien 2004; Aarikka-Stenroos and Ritala 2017; Senyo et al. 2019), and ecosystem orchestration into value creation (Shen et al. 2024).

Recently, the ecosystem concept has been used to examine the constructions sector by Pulkka et al. (2016), and further, the new concept of wooden multistory construction (WMC) (Toppinen et al. 2019, 2022; Viholainen et al. 2021). The BE concept has been suggested to offer a mindset shift in the construction industry, as it highlights interorganizational collaboration and learning to aid companies innovate and adapt to future change together, supported by increased interdependency and developing actor capabilities (Pulkka et al. 2016). The establishment of a BE helps in bringing complementary knowledge together and enables co-learning, in contrast to the traditional procurement methods in the construction industry (Blayse and Manley 2004). Based on Table 1, which presents relevant literature on new residential WMC and wooden retrofits (also borrowing from the more general field of construction innovation and management), a research gap is identifiable in the literature on retrofitting residential multistory buildings with wood. First, building a retrofit project business has been studied more seldomly than new construction businesses (Vainio 2011; Lima et al. 2021; Rajala et al. 2022). Second, there is a research gap in the retrofit literature that emphasizes, first and foremost, the considerations for using building materials more sustainably.

However, we see from Table 1 that the focus of many existing retrofit studies has been on real estate development in general, combined with ecosystem thinking and aligning business models (Rajakallio et al. 2017, 2018). Alternatively, the focus has been on energy efficient residential retrofits and the related business models (Brown 2018; Killip et al. 2020) but with the exception of Holtström et al. (2024) having no explicit focus on material solutions, such as building with wood. Decision-making process of fostering retrofits has been studied from the perspective of optimizing retrofit lifecycle costs and homeowners’ economic benefits in energy retrofits (Jafari and Valentin 2017) or by setting up key criteria and indicators for holistic sustainability and a value-based decision-making support framework for renovation (Kamari et al. 2017). Instead, the premises of our research stem from focusing on wooden materials as a starting point and aim to build new insight on this phenomenon from the perspective of early-stage decision-making at a project scale.

| Table 1. Key concepts and examples of literature concerning the business ecosystem (BE) and dynamic capability theories, with linkages to some existing studies on wooden multistory construction (WMC) and retrofits. | ||

| Key concepts of the business ecosystem (BE) and embedded dynamic capabilities | Earlier literature on new residential wooden multistory construction (WMC) focus | Earlier literature on (wooden) retrofits |

| Value co-creation (Kandiah and Gossain 1998; Aarikka-Stenroos and Ritala 2017; Senyo et al. 2019) Niche creation (Iansiti and Levien 2004) Knowledge sharing and collaborative partnerships (Wulf and Butel 2017) Complementary capabilities (Teece 2009, p. 15) Symbiotic collaborative relationships (Kandiah and Gossain 1998; Senyo et al. 2019) Network management (Aarikka-Stenroos and Ritala 2017) Dynamic capabilities and strategic management and change (Helfat et al. 2007; Teece 2009; Teece et al. 2016) | Value creation in construction networks (Pulkka et al. 2016) Shared logic in WMC projects (Toppinen et al. 2019a) Collaboration, knowledge transfer, and end-user involvement in BE (Brege et al. 2014; Stehn et al. 2021; Viholainen et al. 2021) Benefits, barriers, and opportunities of WMC (Riala and Ilola 2014; Gosselin 2017; Franzini et al. 2018; Toppinen et al. 2019b; Vihemäki et al. 2019; Lazarevic et al. 2020; Stehn et al. 2021; Mark-Herbert et al. 2023) Internal and external competitiveness factors (Toppinen et al. 2019b) | Real estate development; need for complementarity & integrated solutions and mutual alignment of business models (Rajakallio et al. 2017, 2018) Energy efficiency: Business models in residential retrofits (Brown 2018; Killip et al. 2020) Renovations lacking standards or green certificates (Mahapatra et al. 2013) Decision-making and collaboration in retrofits (Jafari and Valentin 2017; Kamari et al. 2017; Holtsröm et al. 2024) Wooden retrofits: Technical studies from civil engineering (Larsen et al. 2011; Cronhjort and le Roux 2014; Jaksch et al. 2016; Pomponi and D’Amico 2017) User-orientation perspective (Soikkeli and Sorri 2014) |

Many barriers hinder the emergence of new residential WMC according to the literature and these also apply to the wooden retrofits in multistory buildings. These include technical factors, such as slow technology transfer; issues of material durability and availability; legal barriers, such as building code implementation and inefficient policy measures. Costs, in relation to capital, materials, construction, and long-term maintenance are considered hinderances to WMC, as, for example, the processes are not seen to be developed to the level of prevalent materials, such as concrete (Riala and Ilola 2014; Gosselin et al. 2017.) However, costs are controversial in the literature, as acknowledged by Gosselin et al. (2017) and Toppinen et al. (2019). This also applies to reduced costs due to a higher construction rate enabled by prefabrication as a motivation for WMC. Also, Mahapatra et al. (2013) noted that energy standards, audit reports, and certificates of renovated buildings appear to be missing in renovation markets dominated by handicraft-based individual solutions.

Nonetheless, the literature also recognizes benefits from or opportunities for WMC, which could also apply to the use of wood as a retrofitting material. Both Franzini et al. (2018) and Gosselin et al. (2017) mention, as key benefits for WMC, the technical qualities of engineered wood products; the sustainability or environmentally friendly quality of wooden materials; the speedy construction practices; and intangible values, such as esthetics or quality of living. In Brege et al. (2014), along with gains in lower carbon footprint, key strategic aspects in the WMC business model are related to maintaining cost competitiveness and increasing construction speed with prefabrication.

Opportunities for WMC include public sector strategies fostering industrial wood construction (Vihemäki et al. 2019), and the WMC business itself creates new opportunities. For example, use of hybrid solutions, namely concrete and steel with wood, and adding to wood use in construction along with new forms of collaborations between actors formerly disconnected from each other (Brege et al. 2014; Toppinen et al. 2019).

The roles and responsibilities of different actors in the project-based construction ecosýstem are an important aspect. In Killip et al. (2020) on the UK energy retrofit market, six roles were identified in the construction value network, combining aspects of manufacturing, distribution, on-site construction, and end-of-life product disposal. The study also found that merchants and manufacturers were beginning to take a keener interest in the end-of life disposal of products, which supports circular economy aspirations (Killip et al. 2020). According to Killip et al. (2020), the influence of installers and on-site builders over detailed specification and choice of materials was emphasized on the UK renovation market. In addition, a new kind of collaboration in decision-making, namely engagement with current residents and housing company boards and the new kind of wooden element solution providers differentiate retrofit building projects clearly from the regular WMC projects (Holtröm et al. 2024).

The new knowledge when moving from new construction to wooden retrofit projects requires a capacity among involved actors to learn and implement new building techniques and innovations in the form of dynamic capabilities (Teece et al. 2016), which requires a change in mentality for companies to enable higher-order learning. Dynamic capabilities are vital for firm survival in turbulent times of market or regulatory uncertainty (Helfat et al. 2007; Teece et al. 2016; Santa-Maria et al. 2021). These capabilities differ from the ordinary capabilities of firms, which, according to Teece (2014), are operational, administrative, and governance capabilities and are more concerned with sustaining current products and services and are suitable for stable times. Industrialized house construction has only rarely been viewed through the lens of dynamic capabilities (Brege et al. 2014; Stehn et al. 2021) and only very recently in the context of retrofit extension projects (Holtström et al. 2024). The three main categories of dynamic capabilities are 1) sensing of opportunities and threats; 2) seizing opportunities, and 3) transforming, renewing, or reconfiguring the intangible and tangible assets of businesses (Teece et al. 2016; Stehn et al. 2021).

The case of wooden retrofitting, as highlighted earlier, calls for changing decision new type of actor groups like current residents and housing company boards. The processes and capitalization of early building techniques enable engagement of new type of actor groups like current residents and housing company boards to learn and experiment with these novel building techniques. These are adaptable to the conditions of the existing buildings, in order to add value to the already built environment (Holtström et al. 2024.)

3 Data and methods

The study began by quantitative mapping of WMC and wooden retrofit projects and their affiliated actors in Finland. Information was searched from various reports, news articles, and Google searches and by attending webinars on wooden construction. The mapping included the projects, timing, location, actors, and type of actor (e.g., construction company, architect) and which organizations have collaborated. The original interest was whether the actors in both new WMC and wooden retrofits are the same and are there linkages in the actors between the two spheres of business.

During the mapping, finding information on wooden retrofits in multistory buildings proved extremely difficult, whereas more information was available on WMC and affiliated actors. This indicates the new WMC to be more established activity in the Finnish context. Thereby, knowledge of wooden retrofit projects in Finland was supplemented from other data sources and thematic interviews. However, this initial search painted a clear picture of the actors that are active in the wooden retrofits’ field. These active actors had been involved in relatively recent projects or planned wooden retrofits projects. Some had also been involved in new residential WMC projects. This mapping of the actors and estimating their topical relevance to the study led to the interviewee selection.

Interviewees were contacted by e-mail and phone. Almost all contacted experts agreed to interview except for two experts that declined due to time constraints and four other people did not reply. The non-responses are in some cases connected to changes in personnel at organizations, as in some cases several years have passed since the implementation of some of the projects. Nonetheless, from the tracked 22 wooden retrofits, we interviewed one or more actors that represented in total 18 projects. Interviewees represented 15 companies, 5 cities, and two intermediary organizations (see Table 2.)

As our focus of the study was to understand a topical phenomenon, in its formative phase and heavily relying on narratives, our main empirical data collection and analysis relied of qualitative research (Silvermann 2000). Thereby, the empirical analysis of the phenomenon included the gathering of qualitative interview material, which was the main original data source of the study with its rich and detailed expert views. This qualitative content analysis consisted of thematization of interview data with a total of 27 actors. The chosen qualitative content analysis enabled us to devise carefully constructed categories on the newly collected interview data set, and throughout the analysis process interactively revise and clarify these categories for reliability (Drisko and Maschi 2015).

The interview data were collected during fall 2021 and spring 2022 (see details of the selected interviewees in Table 2). At the time of the interviews, the COVID-19 restrictions were still largely in place, and therefore only one interview was conducted face-to-face, others were conducted online via Teams. The length of the interviews ranged from approximately 30 to 120 minutes. The special focus of the interview discussions for this study related to the wooden retrofit projects: narratives (what happened and why did the informant become involved with such projects); the strengths of wood in retrofits; and the perceived benefits that the wooden retrofit projects had brought to the informants to determine the motivation behind these.

Also, we inquired who were the project leaders to determine the key actors of wooden retrofit projects, which consequently brought up many discussions on decision-making behind the projects. Several interview guides (see Supplementary file S1) were used, and the common overall themes were adjusted for various actor groups, to enable gathering specific information that each actor group was an expert of. These actor groups consisted of a) producing companies with involvement on both WMC and wooden retrofits; b) companies with involvement solely with wooden retrofits; c) owners and investors, d) municipalities; and e) intermediary organizations.

Initially, the interview data were coded and categorized simultaneously in Atlas.ti and Excel, first by marking down observations and as the observations grew the upper themes and categories were attached to the themes and keywords of the BE literature. For instance, as the interviewee represented a housing company and was discussing their decision-making and sometimes simultaneously discussed for instance the key actors, that transcribed piece of text (e.g., a sentence or a paragraph) would be coded in Atlas.ti: ”decision-making”, ”decision-making housing company”, “key actor” and sometimes “narrative”. Thereby, our analysis was an evolving process with several analytical layers on top of each other, to better grasp the essence of the messages of our interviewees.

| Table 2. Description of the interviewees linked with emerging wooden retrofit business ecosystems (BEs), including affiliations, professions, and transcription codes. | |||

| Code | BE actor type or branch of city | Profession of interviewee | Wooden retrofit project(s) (no in total) |

| C-01 | Material manufacturers and suppliers | Project sales manager | 8 |

| C-02 | Design engineers | Wood technology manager | 2 |

| C-03 | Design engineers | Retrofit head of division | 2 |

| C-04 | Design engineers | Technology manager | 2 |

| C-05 | Design engineers | Wood structural design development manager | 1 |

| C-06 | Architecture | Architect | 2 |

| C-07 | Construction company | Property managing director | 3 |

| C-08 | Energy efficiency product and service provider | Managing director | 1 |

| C-09 | Design engineers | Managing director | 2 |

| C-10 | Construction company | Managing director | 10 |

| C-11 | Architecture | Architect | 2 |

| C-12 | Design engineers | Executive planner, head of unit | 1 |

| C-13 | Energy efficiency product and service provider | Sustainability consultant | 2 |

| M-01 | City environment | City environmental director | Not applicable |

| M-02 | Living and environment | Director of environmental protection | Not applicable |

| M-03 | City environment | Project manager | Not applicable |

| M-04 | Strategic land use, mobility, and housing politics | Specialist adviser | Not applicable |

| M-05 | Real estate development | Head of real estate development | Not applicable |

| M-06 | City environment | Head of environmental protection | Not applicable |

| M-07 | Urban planning office | Head of unit, city plan coordination | Not applicable |

| M-08 | Housing project development unit | Contracted architect | Not applicable |

| M-09 | City environment | Head of project | Not applicable |

| M-10 | Climate and environmental policy unit | Development manager | Not applicable |

| O-01 | Rental housing company | Managing director | 2 |

| O-02 | Housing company | Chair of housing company | 1 |

| I-01 | Knowledge broker | Associate professor | Not applicable |

| I-02 | Knowledge broker | Project manager | Not applicable |

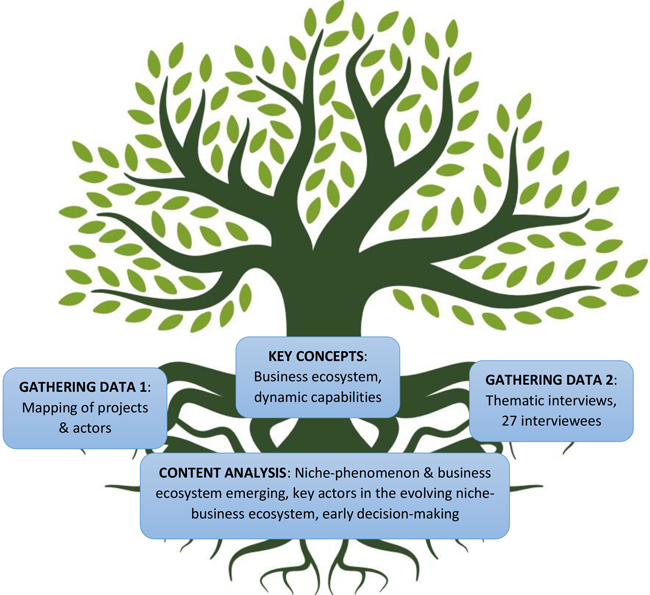

In our research process (see Fig. 1), we applied triangulation of the data and methods (Flick 2018) in various forms. First, we used two interlinked concepts of the BE and dynamic capabilities to outline the agility of businesses creating value in changing business environments. Second, we used multiple data sources in our study. We combined the initial actor mapping data collected via the Internet and a media search of the WMC and wooden retrofit projects and actors with large qualitative thematic interview data for convergence, complementarity, and divergence between datasets (e.g., we could check between the datasets the information on wooden retrofit project actors, who seem to be the key actors in terms of recent activity, number of projects and collaborations). Third, the interview guides were jointly developed by several researchers, and the interviews were conducted by two individuals to ensure impartiality and objectivity. Fourth, the recorded interviewed data were transcribed in Finnish by a third-party company for uniformity and precision. Fifth, the interview data were triangulated, as they consisted of the producers of these exceptional projects, the wooden retrofits solutions of consumers, and two knowledgeable outside informants, yet with project instigation capabilities to strengthen the analysis with multiple viewpoints (see Table 2 for interviewee details). Sixth, at least three researchers cross-checked that the used data and the created themes, categories, and codes were in line with the main study concepts as a supportive tool for reliable data interpretation.

Fig. 1. Illustration of research design consisting of multiple data sources (mod. background picture ©[artKaisen] via Canva.com).

We aimed to enhance the validity and reliability of our research findings and to gain in-depth understanding of our research question by viewing the interview material from various angles and through the lens of different observers. Fig. 1 illustrates the research design, rooted in iterative and interlinked research phases. We often absorbed information simultaneously and cross-checked between the key concepts and data sources while conducting the content analysis (along the lines of reflection and design thinking in Jungmeister (2016)).

4 Results

4.1 Wooden retrofit actors

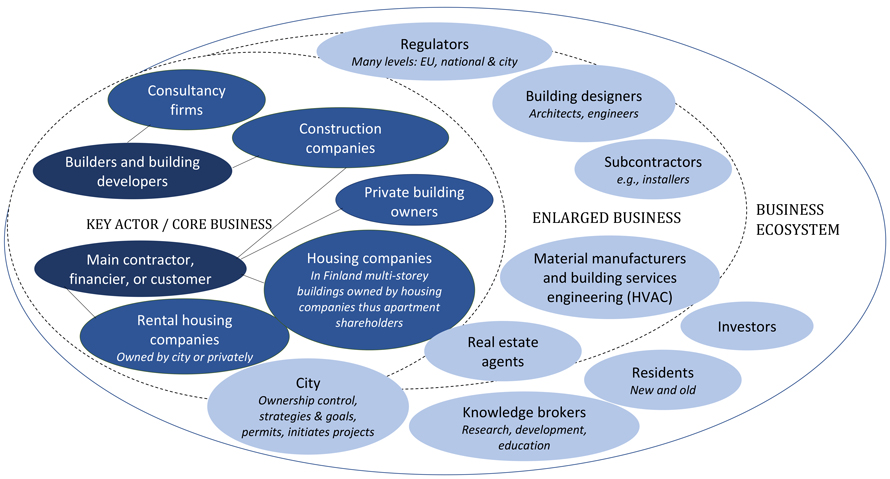

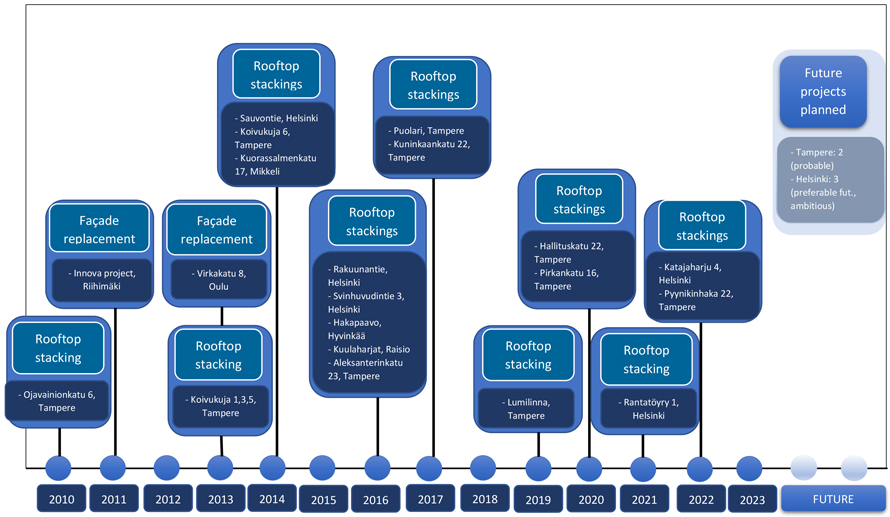

We mapped organizational actors of wooden retrofits and related project-based business networks. This information gathering resulted in approximately 70 WMC or wooden retrofit projects (built or planned for the near future) from 2003 onwards, including a total of 243 affiliated actors. Of these 70 projects, 22 were detected to be wooden retrofit projects in housing and residential buildings, either in the planning phase, under construction, or already built. Eighteen of the projects were completed in 2022. Two of these were facade replacements and 16 were rooftop stackings. The analysis of these projects reveals multiple actors in various layers of the BEs of wooden retrofits in multistory buildings (Fig. 2).

Fig. 2. Range of actors in the wooden retrofits in multistory buildings and their position in the business ecosystem (BE).

In addition to the key actors of the wooden retrofit BE (marked in the darkest color), the other actors are also significant. Regulators and knowledge brokers are found to create the windows of opportunity for the key actors by setting the rules of the game (laws, strategies), frameworks of economic possibilities (project funding, economic incentives) and informing (e.g., by marketing, researching, and piloting). The full entity of an enlarged business complemented with various building design actors, material manufactures, and building services engineers (HVAC) ensures the practical realization with architectural, technical, and material-related properties. Actors of the enlarged business may also enhance sustainability-related attributes, such as low-carbon building design, if so desired by the key actors.

4.2 Origin and evolution of wooden retrofit projects

Among the wooden retrofit actors, the projects of this area were explored in more detail (see Fig. 3), to understand the dynamics that have enabled the emergence of the 22 identified wooden retrofit projects. The collected project narratives reflected the evolution of one large Finnish city and the city-owned rental apartments, in which a producer (a wooden material manufacturer) ended up being a part of multiple projects, both in new WMC and in retrofits with wooden rooftop stackings. Historically, the city-owned rental apartments manage “a large part of the historically protected wooden buildings and residential buildings in [the city in question]” (Managing director, code: O-01) that were built already in the early 1900s. In the 2010s, they have also ventured into building a few new wooden multistory buildings. More recently, they have contributed to the planning of wooden retrofits in two regular, suburban multistory buildings that they own, as described by the actor: “It [the process] is actually quite varied and [we have] all kinds of activities in which wood is being used.” (Managing director, code: O-01).

Fig. 3. The identified 22 examples of wooden retrofit projects in Finland. View larger in new window/tab.

The most active actor with multiple projects both in new WMC and in retrofits with wooden rooftop stackings is a particular wooden element producer operating in multiple locations in Finland. The company representative describes how he became aware of an Innova-project which focused on replacing concrete facade elements with wooden elements. He visited the project, to become familiarized with the construction site conditions and to understand how this aspect of the project functioned. Due to another ongoing WMC project, the wooden element producer did not have the capacity to participate in it, yet awareness of it affected the company’s later decisions to broaden their business model towards wooden retrofits.

In such project initiation, the motivation to broaden construction to wooden retrofits was based on the following reasoning:

“These wooden multistory constructions, which we have now made more than a dozen of, have been one of my main tasks, to get them moving [into production]. And [I must also] be in the background, to influence their direction [they are headed in], [to] develop the projects, so that wooden multistory buildings would be in our production regularly. But of course, [this is] not enough for our production, we must sell a lot of other things [as well]. And very quickly, in these same circles of architects and other [actors], and [in the] project reports, [the idea] of retrofits and additional building was brought up.” (Project sales manager, code: C-01)

Thereby, the origins of novel innovations of retrofitting with wood can be traced back to traditions of organizations and experiences of the individual actors that can be activated as the opportune moment arises in the current settings.

4.3 Early decision-making models for wooden retrofit projects

Next, we will describe the five alternative decision-making models for project initiation based on our data (see Table 3). In the mid-2010s, a few wooden rooftop stacking projects were carried out in Helsinki. First, a wooden rooftop stacking was carried out on Kulosaaren Svinhufvudintie 3 (project finished in 2016), which led to another project in Rantatöyry (finished in 2021), with more or less the same network of actors: the customer, contractor, and wood element manufacturer. Second, there was another rooftop stacking project (finished in 2016), which began at the opposite side of the same city (see Table 3).

The background of the second project, called Rakuunantie (code A, see Table 3 for the use of capital letter coding), was elaborated by the architect. Both external and internal factors contributed to the initiation of the project. Externally, the Finnish building code on fire safety had just changed, allowing multistory buildings to be rooftop-stacked with lightweight structures, including wooden materials. Also, the city’s strategy had changed to favor condensing of the city fabric. An active real estate agent was an internal factor behind the project, as described by the architect:

“We were contacted by a real estate agent (…), who was very excited of rooftop stackings in particular. He saw in them the future of city fabric condensing, in new layers to be built on top of the roofs. . He saw that there is a huge potential in Helsinki, [with] so many roofs, especially flat roofs. And his idea was that the foundations [for rooftop stackings] would be easier to establish on flat roofs. (…) And this particular housing company’s real estate manager had attended the Real Estate Manager Days [an event for real estate managers], |and] became excited about the topic. And he needed a partner, an architectural firm.” (Architect, code: C-06)

The wood element manufacturer mentions that Rakuunantie was the first rooftop stacking project that they accomplished. However, while the contracts for this first site were being signed, the wood part manufacturer concurrently “opened negotiations and execution for another site, a stone’s through away” (Project sales manager, code: C-01), a site called Sauvontie. This indicated that a new business segment, wooden rooftop stacking, was opening for the wooden element manufacturer.

Several wooden rooftop stacking projects were simultaneously initiated in another city (Tampere, Finland). In one chain of events, one construction company has been actively producing rooftop stackings in the city area and has worked on a total of 15 projects (code B, see Table 3). However, not all of these have been produced using wood to a substantial degree, nor has wood use been favored in the projects, as the following quote elaborates:

“If the structures can bear [the weight], we will quite often make the structures from concrete as there are issues such as sound proofing [to consider]. But (…) it is quite case specific [how much wood can be used], but these rooftop stacking projects have used significant amounts of wood, each of them has used some.” (Managing director, code: C-10)

Thus, this construction company used hybrid materials and their use of wood varies, as they have typically used wood in the roofs and intermediate floors of their rooftop stacking projects. However, wood was also used in the facades and intermediate floors of certain projects.

The customers of these rooftop stackings have mainly been private owners or housing companies (code B, see Table 3), apart from one contract that was made for the city-owned rental apartments (code C, see Table 3). All housing company projects were located in the city center. Conversely, the retrofit project for the city-owned rental apartments was in a suburb. Behind these projects lies the city’s positive attitude toward condensing of the city fabric. This has been an incentive for the companies and builders to study projects that allow additional construction, either by rooftop stacking or by adding buildings to the same plot/property: “[This] is [the route through which] we have gotten them [the projects], and then [we have been in] contact and begun [a project], made an agreement with a [housing] company and then made [the construction]” (Managing director, code: C-10). But this path, chosen for constructing a dozen wooden or hybrid rooftop stackings, has not been easy, as the actor describes: “no one else has been crazy enough to make these in our city, sometimes it doesn’t make any sense, [as] they are financially such tight [projects]” (Managing director, code: C-10).

Despite the opinion of the previous construction company, another construction company was already planning and executing two consecutive wooden rooftop stacking projects, with a new project in mind for the future. The wooden rooftop stacking process in this second chain of events began through the initiative of a private building owner that held significant power in the construction company itself. The project initiation (code D, see Table 3) began as narrated: “The history [of the building] is that the company’s contemporary chair of the board of directors and owner (..) had previously bought the whole property. And (…) it was a seven-story building and [had] an eighth floor, which was cold attic space. And then a land zoning change was made, in which a permit was applied to add two floors to this project. And in practice, the project proceeded so (…) that an old, cold attic floor was torn down and two new floors of rooftop stacking were constructed. [Consisting] purely of apartments, 24 apartments” (Property managing director, code: C-07).

The construction company representative described how the project’s decision process had been easy: “(…) there is only one property owner now that remains, and [therefore] it was kind of an easier project from the standpoints of design, building, and corporate management than a traditional rooftop stacking project, where, to begin a project, you [need] a unanimous decision from the board, the share… or owners. There was only one person, who basically decided that the project will proceed. In that regard it was easy to move things forward” (Property managing director, code: C-07).

The project was a success according to the construction company representative, as they received an award from the city, which favors rooftop stacking. This then led to another rooftop stacking project, in which wood was used to an even more significant degree. The second rooftop stacking (code E, see Table 3) was built on top of an old factory building, which was converted into residential use. For building technical reasons, concrete could not be used, as the existing structures would not have borne the weight. A light material was therefore needed, and wood was used “nearly everywhere” (Property managing director, code: C-07) in this second rooftop stacking project.

This project was extensive, as it involved 130 new apartments and three housing companies that were grounded by the construction company. According to the construction company, the decision-making process was easy, as it was “in our own hands” (Property managing director, code: C-07) and “a great learning experience (…) foremost [experience] in such change of use projects, where some old factory building is transformed into residential [living]. [This] has not really been done here before (..) [so] a bit of a first step into what all it entails” (Property managing director, code: C-07). A third rooftop stacking project is being planned in the future by this construction company, this time together with a housing company. At the time of the interview, the project was in the land zone development phase (code F, see Table 3). Thus, the decision-making model will be slightly more challenging, as the construction company must deal with the housing company and the shareholders’ meeting process, which requires “quite close cooperation, dialogue, and perusing through the matters for the project to proceed” (Property managing director, code: C-07).

Yet another type of rooftop stacking process (code G, see Table 3) originated in a favorable land zoning decision around 2004 in the same city (Tampere), to be completed in 2020, through an event that occurred on the neighboring property of a particular housing company’s property:

“There was this old movie theater on our neighboring property, which, through a plan provision, ended up being bought by a construction company. And [they] applied for a plan provision for the old building to be torn down and to build a new one. So, in the same context, [we saw] that it would be possible to also alter our housing company’s plan, and this would enable rooftop stacking (..). We kind of seized the opportunity, and it was later reasonable to execute the rooftop stacking.” (Chair of housing company, code: O-02)

This third process was later carried out in a group self-building (Heffernan and Wilde 2020) format, which is quite exceptional, yet is perceived as a more economical alternative than involving a construction company for such a small-scale project. Thus, the housing company involved a joint building consultant instead of a construction company and then led the process and involved a real estate agent to find suitable new residents for the apartments built using group self-building (see Table 3 for the different operational and decision-making models of wooden rooftop stackings/retrofits). This project also has a continuation, as the group self-building consultant at the time of the interview had already begun a rooftop stacking construction project with another housing company in the same city (code H, see Table 3).

| Table 3. Dynamic capabilities and the five early decision-making model forms and associated difficulty, applied by the key actors of a niche business ecosystem of wooden retrofit projects. | |||

| Key actors and decision-making process forms | Difficulty level of decision-making | Location in city | Dynamic capabilities |

| 1) Private building owner decides, involves a construction company Project code: D | Low | City center | Private building owner senses and seizes the opportunity to make a profit in the more expensively rented city center with new apartments through rooftop stacking |

| 2) City rental housing company decides, decision-making has positive synergies with city strategies and goals, involves a construction company Project codes: C, I, J | Low | Suburban | Both the city rental company and the city itself are sensing opportunities with awareness concerning climate, environmental, and low-carbon needs, seizing the opportunity for social facelifts in suburban areas |

| 3) Construction company decides and executes, grounds housing companies Project codes: E, F | Low | City center | Construction company senses and seizes new business opportunities to make a profit if it is technically optimal, location is in expensive area |

| 4) Housing company shareholders decide and involve a builder, e.g., construction company, developer, real estate agent, steward, or architect Project codes A, B | High | City center | Housing company senses and seizes the opportunity to finance other types of necessary renovations with rooftop stackings by selling the building rights and by acquiring new apartments, also through new shareholders to the housing company paying maintenance charges. The builder, building developer, or some key interested individual(s) senses and seizes the opportunity as well |

| 5) Group self-build housing model: Housing company shareholders decide and involve a consultant, who either directly finds new residents for joint building or involves a real estate agent Project codes: G, H | High | City center | Housing company senses and seizes the opportunity to finance other types of necessary renovations with rooftop stacking by selling the building rights and by acquiring new apartments and also through new shareholders to the housing company paying maintenance charges |

In another location, in southwest Finland, a rooftop stacking was being planned onto a multistory building from the 1970s, located in a mid-sized Finnish municipality. Wood use was not, however, an obvious choice for the project (code I, see Table 3):

“The city had this property, Asunto Oy Kuulaharjat, and two multistory buildings are connected to it. (…) and new solutions were searched for these [buildings]. The Turku shipyard industry was in bad shape at the time, a lot of people from the shipyard [were] unemployed and [searching] for new jobs. And the idea was to use the shipyard [and] ship-building field solutions in a retrofit project. (…) So, we began planning it, and the shipping field was ambitiously involved, but then the shipping field began to export really well again (…) and all the shipping field actors disappeared (…). Thus, the decision was [made] to build rooftop stackings onto both buildings; wood structured [stackings] because they had foundations, pilings, that had been sized quite tightly on the existing building, and there was not possibility to [increase] their weight.” (Managing director, code: C-08)

These buildings were retrofitted quite extensively. In addition to the wooden rooftop stackings, the building retrofits included, for instance, the construction of new elevators, surface renewals, and installing new apartment-specific exhaust air heat pumps and solar panels. During this project, the wood part manufacturer and the provider of the energy efficient building services engineering were not involved very much with each other’s practical work, excluding some of the designing phase. But both actors separately envisioned that they could be involved more, as the wooden part manufacturer imagined technical solutions that could be integrated into their wooden elements and the building services engineer envisioned a concept consisting of a product package that would be marketed together to municipalities, rental apartments, and student apartments. However, this would require getting the actors around the same table and openly searching for low-carbon solutions.

Returning to the first case city (Helsinki), the most ambitious retrofit plans were found (code J, see Table 3). The city itself had organized an architectural competition for retrofitting a city rental housing company owned residential multistory building with wooden structures.

“[It] is not typical at all to [hold] an architectural competition on a residential site or on a retrofit site, but this [site] did.” (Managing director, code: O-01)

Both Finland’s and the city’s carbon neutrality goals were at the base of the project. Also, the city wanted to perform a facelift on the suburban area in which the pilot multistory building was located in. An excited young architect noticed the architectural competition, and the architectural firm decided to take part in the competition and form a team: another architectural firm and a design engineer. These were easily found, as the other companies gathered for the team were located in the same building and there was a lot of existing cooperation among the companies. This became the winning team:

“And we won it [the competition]. There were many reasons, of which the interesting structural solution was not the least important (…) through the structural solution we were able to save the base floor, [to keep] the building’s base floor intact, so it didn’t need to be torn down.” (Architect, code: C-06)

In addition to saving part of the existing building structures, the plan was to retrofit the building facades with wood and to construct wooden rooftop stackings.

After the competition, the continuation of the project was left open and several open questions on costs efficiency remained. Thus, the winning team, together with the city’s residential construction office, decided to apply for funding from the Ministry of the Environment to advance and cultivate the planning further. They received the financing, and further development was ongoing at the time of the interviews, including cost calculations in relation to publicly available funding and carbon footprints. As construction is expensive in general, the project planners are making an effort to ensure that various calculations lead to a model that would fit in with the financing frame of ARA – the Housing Finance and Development Centre of Finland, to enable this new retrofitting concept and financing model becoming mainstream.

We were able to detect five models that sum up the dynamic capabilities and the five early decision-making models applied by the key actors of niche BEs of wooden retrofit projects (portrayed in Table 3). Within the rare and exemplary cases of wooden retrofits implemented and planned so far, the sensing and seizing of opportunities are apparent dynamic capabilities applied by the key actors. On the other hand, the higher-order dynamic capability of reconfiguring the business activities based on wood use seems to be lacking, even among these forefront actors. City-owned housing companies stand out as being the customer key actors that are most aware of seizing opportunities for climate benefits and for facelifts in less appealing suburban areas. On the other hand, producing actors state that they will realize the wishes of customers, also in cases where a customer is willing to pay for climate benefits and requires wood use.

5 Discussion

This study performed a real-life project-level analysis on wooden retrofits and studied their emerging actor networks and their interplay in the local BEs in Finland. Beyond Finland, wooden retrofit projects have been identified in a few other European countries such as Estonia and Sweden (Pihelo et al. 2017, 2020; Svensson 2022; Holtström et al. 2024). Nonetheless, the use of prefabricated wooden elements in multistory building retrofits has remained a niche even internationally, with an overall focus on energy efficiency improvements (Pihelo et al. 2017, 2020) or a wider front on improving social and environmental sustainability (Svensson 2022).

Regarding our first research question on the emerging ecosystem of actors, the key actors in project-based wooden retrofits were found to be scarce as we could only identify 22 projects. Nonetheless, a small group of ca. a dozen devoted actors have continued being active around vertical building with wooden rooftop stackings. Builders, namely the construction companies; joint building consultants; and the main contractors, financiers, or customers, namely city-owned housing companies, housing companies, and private building owners were key actors found at the core of the local BEs in Finland (see also Fig. 1). By mapping the business network actors and their roles, we were able to detect some early-stage issues in the project initiation of wooden retrofits, pinpointing certain barriers to change and identifying potential “agents of change”. Furthermore, we found that there is certain coincidental nature inherent in the realized retrofit projects available for the earlier years of 2010–2016.

Interestingly, in a few cases, an opportune moment has presented itself to the actors involved, and five models of early decision-making could be identified (see Table 3). All collected evidence shows a certain degree of difficulty, inertia, and lack of harmonization in early-stage decision-making processes. Our findings confirm the importance of cost calculations as a basis for decision-making presented by Jafari and Valenti (2017), as most of the identified Finnish key actors of builders and customers in our study stated that they based their decision-making on economic reasoning. However, of the identified key actors, city-owned housing companies seemed to be more motivated also by wider sustainability goals, linked to their interests in uplifting and transforming aging suburban areas. This decision-making model by city-owned housing companies most aligns with the value-based, holistic, and systemic decision-making model described by Kamari et al. (2017).

Hence, external factors, such as favorable changes in building codes, new city strategies for urban densification, or a neighboring property undergoing city plan provision, were found to enable the housing company to introduce rooftop stacking projects. However, the incidental nature of these projects is visible, mainly relying on active and enlightened individuals such as the chair of a housing company (with experience in chairing boards of many housing companies) or a young and excited architect inspired by something new.

Motivations for project development among actors were found to be driven from urban densification strategies, through the improvement of suburban neighborhood attractiveness, or through the efficiency gains of space utilization available from vertical building. Based on this analysis, even the occasional frontrunner actors who had ventured to the side of wooden retrofits admit that sustainability aspects were seldom at the core of project initiation in the past projects (as also indicated in Table 3).

Over time, the identified niche ecosystem of the actors has moved toward more ambitious plans for deep renovation with wood, including rooftop stacking, insulation with wooden facades, and apartment-specific exhaust air heat pumps and solar panels. This resembles the development in Sweden, where the research and development agenda is more focused on the possibilities of wooden retrofits in multistory buildings (Svensson 2022).

Our results are in line with Holtström et al. (2024) who identified financial benefits from higher income through additional square meters in the extension building, cost savings from energy in the entire building after completion, and better indoor climate from the use of wood beams. Furthermore, the choice of wooden material in rooftop stackings has often been based on attributes such as lightness, availability, and cost-effectiveness. Typically, technical, and financial realities have guided the material choice. This is in line with previous research on wooden retrofits in multistory buildings, which technical feasibility studies have focused on (Larsen et al. 2011; Cronhjort and le Roux 2014; Jaksch et al. 2016; Pomponi and D’Amico 2017). Our results are also interesting in light of Toppinen et al. (2022), who found that a higher degree of prefabrication associated with new residential WMC is seen to influence the reorganization of logistics, enabling faster building processes and lean material use.

Regarding our second research question, we see that the phenomenon is still largely a niche innovation, with certain barriers in the very early phases of decision-making hindering project initiation. Also, a certain degree of difficulty in early-stage decision-making process is related to ownership and to the slowness of the decision-making among housing companies (see Table 3, especially models 3–5). In contrast to building ownership-related slowness or difficulties in decision-making, the producing side could more swiftly execute retrofit projects with wood, if so desired and commissioned by the building owner(s).

Also, based on Table 3, the initial phase in a decision-making process for starting a wooden retrofit project seems to be faster with private building owners, rental housing companies, and construction companies. Conversely, the democratic decision-making process among private housing company shareholders seems substantially more time-consuming because of the required majority decision. This decision-making process may be even slower if the housing company does not own building rights for rooftop stacking, as it will need to apply for building rights. The involvement of city officials and acquiring plan provisions for new building rights or building permits may take a very long time, as the permits must follow the landscaping rules of the city, and this may require involving city museums in the planning process.

Regarding the dynamic capabilities involved (Helfat et al. 2007; Teece et al. 2016) among the key actors, the city-owned housing companies seem to be most aware of seizing opportunities for climate benefits and the potential for conducting facelifts in less appealing suburban areas. However, the reconfiguration stage of their business models is yet hardly visible in the emerging retrofit BE. Among the actors engaged with the few existing wooden retrofits, some had also synergies with new residential WMC. This could, cautiously, be interpreted as a very early sign of business model reconfiguration through the development of new strategies, goal setting, or through building deeper knowhow in wooden construction and retrofitting. Gaining sufficient learning benefits from project to project is still very limited. Examples of more systemic solutions can be found from city-owned rental housing companies, and as Finland and the other Nordic countries have large levels of aging rental housing stock, there is market demand in transferring these systemic solutions.

Comparing our results with earlier literature on dynamic capabilities (Helfat et al. 2007; Teece et al. 2016; Stehn et al. 2021), the actors of these niche BEs of wooden retrofit projects had typically applied the first-order dynamic capabilities when sensing an opportunity by assessing and identifying it. Some second-order dynamic capabilities of seizing or utilizing an opportunity in practice were also identified in these projects, including decision-making skills based on either existing or new knowledge and technologies. However, reconfiguring the company’s intangible and tangible asset base by re-organizing and redesigning business models by adding flexibility to standard operational models was not yet visible. Hence, the collective set of companies in the wooden retrofit BE is not yet strong enough to advance this building solution in its most ambitious form.

Previous research from the UK retrofit market by Killip et al. (2020) highlighted industry practices, skills and knowledge, roles and responsibilities, innovation, engagement with installers, and the role of policy to be key sources of capabilities. In contrast, our study remained at a more meta-level in terms of seizing the new business opportunities, which clearly calls for building capabilities such as new practices for prefabrication and off-site construction, initiating new collaboration networks, and developing their coordination skills. Essentially, this development would help to meet city-level densification and low-carbon strategies locally. Service businesses, such as installers, were only rarely mentioned by the interviewees and in the media sources.

Compared with the study by Viholainen et al. (2021) from the context of new residential WMC, the required mindset shift, emphasizing an end-user perspective, is needed. This is due to the housing company owners being a highly significant actor group in the niche retrofit business. In retrofits, the building always has a pre-existing owner, and the ownership type determines the decision-making mechanisms and influences the speed of decision-making. Our results contribute to the BE literature underlining that in order to realize benefits to the more functioning business ecosystem, all three categories of dynamic capabilities would need to be present. However, we observe that in case of wooden retrofits in Finland there is still unused potential especially around reconfiguring capabilities when shifting from new WMC to retrofit construction business. Early involvement of the new partners, such as current residents appear as a key factor in order to contribute to a retrofit based value proposition. This is underlining the linkage between two concepts of BE and dynamic capabilities originally brought together in Teece (2009) in consequent applications in the field of urban development and construction (Linde et al. 2021; Holtström et al. 2024).

There are clear limitations to the generalizability of the study findings due to the mainly qualitative approach and the purposive sampling during data collection in a narrow, single-country context of Finland. Nevertheless, our results importantly increase the understanding of the applicability of the BE and dynamic capability approach in the wooden retrofit setting and the forms of early decision-making processes on the project scale. As the retrofit phenomenon is only building momentum, and yet timely in light of the European Renovation Wave (EC 2020b), charting this unknown territory at its initiation phase through qualitative approach and in a single-country context was, therefore, a justified choice.

6 Conclusions

A need for scaling up good practices from these projects involving wooden retrofits is apparent. By concentrating on the early-stage decision-making process, we were able to shed some light on the key actors of a local niche BE. In addition, by identifying the nature of dynamic capabilities, the difficulty level of the decision-making process and the motivations behind the wooden retrofit projects could be demonstrated. However, only time will tell whether we are looking at wooden retrofits as mainstreaming innovation in construction toward material-driven sustainability aspirations and value creation in the already built environment. Nonetheless, as the “rules of the game” change, the legal requirements for monitoring, calculating, and implementing low-carbon new and retrofit construction are inevitably tightening (Bionova Oy 2017; Ministry of the Environment 2019). With this new market, possibilities arise for actors sensing and seizing these novel opportunities to in the long term reconfigure their business activities.

There are many paths that future research may take on this topic, for instance building longitudinal setting for comparative assessments of more diverse geographical locations in project development. Also, new insight could be drawn by focusing on various actor groups, as the roles of residents and housing company boards were missing from this dataset. As a future-oriented phenomenon was examined, methodologically drawing from futures studies could be beneficial for determining the degree of shared stakeholder visions and for identifying pathways to a desirable future, as well as for identifying radical innovations in construction business models.

Authors’ contributions

A. Viljanen - Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Validation, Visualization, Writing – original draft, Writing – review & editing.

M. Kurttila - Conceptualization, Writing – review & editing, Validation, Supervision.

A. Toppinen - Conceptualization, Writing – review & editing, Validation, Supervision.

Funding

“The research was conducted with funding from Strategic Research Council affiliated with Academy of Finland [grant numbers 335241; 335245 and 1358343] for the project “Citizens as agents of change in decarbonizing suburban and rural housing” (DECARBON-HOME) ongoing in 2020–2026 and with the funding of Business Finland [grant number 8348/31/2022] for the project “Resilient urban building and housing solutions from Finnish Frontrunner Firms – Pathways for Global Exports” (FoREfront) ongoing in 2023–2025.

Data availability

Data will be made available on request by contacting the corresponding author.

References

Aarikka-Stenroos L, Ritala P (2017) Network management in the era of ecosystems: systematic review and management framework. Ind Mark Manag 67: 23–36. https://doi.org/10.1016/j.indmarman.2017.08.010.

Amer M, Reiter S, Attia S (2018) Urban densification through roof stacking: case study. In Hartig T (ed) European Network for Housing Research (ENHR 2018). https://hdl.handle.net/2268/226538.

Asdrubali F, Ferracuti B, Lombardi L, Guattari C, Evangelisti L, Grazieschi G (2017) A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build Environ 114: 307–332. https://doi.org/10.1016/j.buildenv.2016.12.033.

Blayse AM, Manley K (2004) Key influences on construction innovation. Constr Innov 4: 143–154. https://doi.org/10.1108/14714170410815060.

Brege S, Stehn L, Nord T (2014) Business models in industrialized building of multi-storey houses. Constr Manag Econ 32: 208–226. https://doi.org/10.1080/01446193.2013.840734.

Bionova Oy (2017) Tiekartta rakennuksen elinkaaren hiilijalanjäljen huomioimiseksi rakentamisen ohjauksessa. [Roadmap to taking the buildings whole lifecycle carbon footprint into account in construction guidance]. https://ym.fi/documents/1410903/38439968/Tiekartta-rakennuksen-elinkaaren-hiilijalanjaljen-huomioonottamiseksi-rakentamisen-ohjauksessa-4B3172BC_4F20_43AB_AA62_A09DA890AE6D-129197.pdf. Accessed 10 March 2023.

Brown D (2018) Business models for residential retrofit in the UK: a critical assessment of five key archetypes. Energy Effic 11: 1497–1517. https://doi.org/10.1007/s12053-018-9629-5.

Capener C, Burke S, Le Roux S, Ott S (2014) Hygrothermal performance of TES energy façade at two European residential building demonstrations – comparison between field measurements and simulations. In: Arfvidsson J, Harderup L-E, Kumlin A, Rosencrantz B (eds) NSB 2014 10th Nordic Symposium on Building Physics, pp 1244–1251. ISBN 978-91-88722-53-9.

Cronhjort Y, le Roux S (2014) Holistic retrofit and follow-up through monitoring: case Virkakatu, Oulu, Finland. In: Arfvidsson J, Harderup L-E, Kumlin A, Rosencrantz B (eds) NSB 2014 10th Nordic Symposium on Building Physics, pp 1171–1179. ISBN 978-91-88722-53-9.

Dauda J, Ajayji S (2022) Understanding the impediments to sustainable structural retrofit of existing buildings in the UK. J Build Eng 60, article id 105168. https://doi.org/10.1016/j.jobe.2022.105168.

D’Oca S, Ferrante A, Ferrer C, Pernetti R, Gralka A, Sebastian R, Veld P (2018) Technical, financial, and social barriers and challenges in deep building renovation: integration of lessons learned from the H2020 cluster projects. Buildings 8, article id 174. https://doi.org/10.3390/buildings8120174.

Drisko J, Maschi T (2015) Content analysis. Oxford University Press, New York. https://doi.org/10.1093/acprof:oso/9780190215491.001.0001.

EC (2019) The European Green Deal. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. COM/2019/640 final. https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1576150542719&uri=COM%3A2019%3A640%3AFIN. Accessed 1 September 2022

EC (2020a) A new circular economy action plan for a cleaner and more competitive Europe. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. COM/2020/98 final. https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN. Accessed 1 September 2022.

EC (2020b) A renovation wave for Europe – greening our buildings, creating jobs, improving lives. COM(2020) 662 final. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0662. Accessed 1 September 2022.

European Environment Agency (EEA) (2022) Modelling the renovation of buildings in Europe from a circular economy and climate perspective. Background Technical Report. https://www.eea.europa.eu/publications/building-renovation-where-circular-economy/modelling-the-renovation-of-buildings/view. Accessed 8 February 2023.

Flick U (2018) Doing triangulation and mixed methods. SAGE Publications Ltd. https://doi.org/10.4135/9781529716634.

Franzini F, Toivonen R, Toppinen A (2018) Why not wood? Benefits and barriers of wood as a multistory construction material: perceptions of municipal civil servants from Finland. Buildings 8, article id 159. https://doi.org/10.3390/buildings8110159.

Global Alliance for Buildings and Construction, International Energy Agency, and the United Nations Environment Programme (GlobalABC, IEA & UNEP) (2019) 2019 Global status report for buildings and construction: towards a zero-emission, efficient and resilient buildings and construction sector. https://iea.blob.core.windows.net/assets/3da9daf9-ef75-4a37-b3da-a09224e299dc/2019_Global_Status_Report_for_Buildings_and_Construction.pdf. Accessed 1 September 2022.

Gosselin A, Blanchet P, Lehoux N, Cimon Y (2017) Main motivations and barriers for using wood in multi-story and non-residential construction projects. BioResourc 12: 546–570. https://doi.org/10.15376/biores.12.1.546-570.

Heffernan E, de Wilde P (2020) Group self-build housing: a bottom-up approach to environmentally and socially sustainable housing. J Clean Prod 243, article id 118657. https://doi.org/10.1016/j.jclepro.2019.118657.

Helfat C, Finkelstein S, Mitchell W, Peteraf M, Singh H, Teece D, Winter S (2007) Dynamic capabilities. Understanding strategic change in organizations. Blackwell Publishing Ltd., Malden, USA, Oxford, UK & Carlton, Australia.

Hemström K, Gustavsson L, Mahapatra K (2017) The sociotechnical regime and Swedish contractor perceptions of structural frames. Constr Manag Econ 35: 184–195. https://doi.org/10.1080/01446193.2016.1245428.

Hurmekoski E, Jonsson R, Nord T (2015) Context, drivers, and future potential for wood-frame multi-story construction in Europe. Technol Forecast Soc Change 99: 181–196. https://doi.org/10.1016/j.techfore.2015.07.002.

Iansiti M, Levien R (2004) Keystones and dominators: framing operating and technology strategy in a business ecosystem. Harvard Business School, Working Paper, pp 3–61.

Jafari A, Valentin V (2017) An optimization framework for building energy retrofits decision-making. Build Environ 115: 118–129. https://doi.org/10.1016/j.buildenv.2017.01.020.

Jaksch S, Franke A, Österreicher D, Treberspurg M (2016) A systematic approach to sustainable urban densification using prefabricated timber-based attic extension modules. Enrgy Proced 96: 638–649. https://doi.org/10.1016/j.egypro.2016.09.121.

Jungmeister A (2016) Innovation and reflectivity in the research process. Cambridge Scholars Publishing. EBSCOhost Academic Collection. ISBN 978-1-4438-0003-7.

Kamari A, Corrao R, Kirkegaard P (2017) Sustainability focused decision-making in building renovation. Int J Sustain Built Environ 6: 330–350. https://doi.org/10.1016/j.ijsbe.2017.05.001.

Kandiah G, Gossain S (1998) Reinventing value: the new business ecosystem. Strateg Leaders 26: 28–33. https://doi.org/10.1108/eb054622.

Karjalainen M, Ilgın HE, Somelar D (2021) Wooden additional floors in old apartment buildings: perspectives of housing and real estate companies from Finland. Buildings 11, article id 316. https://doi.org/10.3390/buildings11080316.

Karvonen A (2013) Towards systemic domestic retrofit: a social practices approach. Build Res Inf 41: 563–574. https://doi.org/10.1080/09613218.2013.805298.

Killip G, Owen A, Topouzi M (2020) Exploring the practices and roles of UK construction manufacturers and merchants in relation to housing energy retrofit. J Clean Prod 251, article id 119205. https://doi.org/10.1016/j.jclepro.2019.119205.

Larsen KE, Lattke F, Ott S, Winter S (2011) Surveying and digital workflow in energy performance retrofit projects using prefabricated elements. Autom Constr 20: 999–1011. https://doi.org/10.1016/j.autcon.2011.04.001.

Lazarevic D, Kautto P, Antikainen R (2019) Finland’s wood-frame multi-storey construction innovation system: analysing motors of creative destruction. For Policy Econ 110, article id 101861. https://doi.org/10.1016/j.forpol.2019.01.006.

Lima L, Trindade E, Alencar L, Alencar M, Silva L (2021) Sustainability in the construction industry: a systematic review of the literature. J Clean Prod 289, article id 125730. https://doi.org/10.1016/j.jclepro.2020.125730.

Mahapatra K, Gustavsson L, Haavik T, Aabrekk S, Svendsen S, Vanhoutteghem L, Paiho S, Ala-Juusela M (2013) Business models for full service energy renovation of single-family houses in Nordic countries. Appl Energy 112, 1558–1565. https://doi.org/10.1016/j.apenergy.2013.01.010.

Mark-Herbert C, Roos A, Nagy E, Sjöström F (2023) Urban planners’ perspectives on public private partnership for wooden multi-storey construction. J Forest Econ 38: 7–35. https://doi.org/10.1561/112.00000542.

Ministry of the Environment (2019) Method for the whole life carbon assessment of buildings. Publications of the Ministry of the Environment 2019:23. http://urn.fi/URN:ISBN:978-952-361-030-9.

Moore J (1993) Predators and prey: a new ecology of competition. Harv Bus Rev 71: 75–86.

Moore J (1998) The rise of a new corporate form. Wash Q 21: 167–181. https://doi.org/10.1080/01636609809550301.

Moore J (2006) Business ecosystems and the view from the firm. Antitrust Bull 51: 31–75. https://doi.org/10.1177/0003603X0605100103.

Pihelo P, Kalamees K, Kuusk K (2017) nZEB renovation with prefabricated modular panels. In: Geving S, Time B (eds) 11th Nordic Symposium on Building Physics, NSB2017, 11–14 June 2017, Trondheim, Norway. Enrgy Proced 132: 1006–1011. https://doi.org/10.1016/j.egypro.2017.09.708.

Pihelo P, Kuusk K, Kalamees K (2020) Development and performance assessment of prefabricated insulation elements for deep energy renovation of apartment buildings. Energies 13, article id 1709. https://doi.org/10.3390/en13071709.

Pomponi F, D’Amico B (2017) Holistic study of a timber double skin façade: whole life carbon emissions and structural optimisation. Build Environ 124: 42–56. https://doi.org/10.1016/j.buildenv.2017.07.046.

Pulkka L, Ristimäki M, Rajakallio K, Junnila S (2016) Applicability and benefits of the ecosystem concept in the construction industry. Constr Manag Econ 34: 129–144. https://doi.org/10.1080/01446193.2016.1179773.

Rajakallio K, Ristimäki M, Andelin M, Junnila S (2017) Business model renewal in context of integrated solutions delivery: a network perspective. Int J Strateg Prop Manag 21: 72–86. https://doi.org/10.3846/1648715X.2016.1249533.

Rajakallio K, Cuthbertson R, Pulkka L, Junnila S (2018) Creating urban platforms – opportunities and challenges for innovation in commercial real estate development. Cities 77: 92–103. https://doi.org/10.1016/j.cities.2018.01.016.

Rajala P, Ylä-Kujala A, Sinkkonen T, Kärri T (2022) Profitability in construction: how does building renovation business fare compared to new building business. Constr Manag Econ 40: 223–237. https://doi.org/10.1080/01446193.2022.2032228.

Riala M, Ilola L (2014) Multi-storey timber construction and bioeconomy – barriers and opportunities. Scand J For Res 29: 367–377. https://doi.org/10.1080/02827581.2014.926980.

Santa-Maria T, Vermeulen W, Baumgartner R (2021) How do incumbent firms innovate their business models for the circular economy? Identifying micro-foundations of dynamic capabilities? Bus Strategy Environ 31: 1308–1333. https://doi.org/10.1002/bse.2956.

Senyo P, Liu K, Effah J (2019) Digital business ecosystem: literature review and a framework for future. Int J Inf Manag 47: 52–64. https://doi.org/10.1016/j.ijinfomgt.2019.01.002.

Silverman D (2000) Doing qualitative research. A practical handbook. Sage, London.

Soikkeli A, Sorri L (2014) A new suburb renovation concept. Int J Archit Environ Eng 8: 630–638. https://doi.org/10.5281/zenodo.1093060.

Stehn L, Engström S, Uusitalo P, Lavikka R (2021) Understanding industrialised house building as a company’s dynamic capabilities. Constr Innov 21: 5–21. https://doi.org/10.1108/CI-09-2019-0086.

Svensson N (2022) Timber on Top slutrapport, Vinnovaprojekt etapp 2, Cirkulärt biobaserat byggande. https://timberontop.se/publikationer/. Accessed 10 March 2023.

Teece D (2009) Dynamic capabilities & strategic management. Organizing for Innovation and Growth. Oxford University Press Inc., New York.

Teece D (2014) A dynamic capabilities-based entrepreneurial theory of the multinational enterprise. J Int Bus Stud 45: 8–37. https://doi.org/10.1057/jibs.2013.54.

Teece D, Peteraf M, Leih S (2016) Dynamic capabilities and organizational agility: risk, uncertainty, and strategy in the innovation economy. Calif Manag Rev 58: 13–35. https://doi.org/10.1525/cmr.2016.58.4.13.

The White House (2021) Federal sustainability plan. Accompanying President Biden’s Executive Order 14057. https://www.sustainability.gov/pdfs/federal-sustainability-plan.pdf. Accessed 27 March 2023.

Toppinen A, Miilumäki N, Vihemäki H, Toivonen R, Lähtinen K (2019a) Collaboration and shared logic for creating value-added in three Finnish wooden multi-storey building projects. Wood Mater Sci Eng 14: 269–279. https://doi.org/10.1080/17480272.2019.1653365.

Toppinen A, Sauru M, Pätäri S, Lähtinen K, Tuppura A (2019b) Internal and external factors of competitiveness shaping the future of wooden multistory construction in Finland and Sweden. Constr Manag Econ 37: 201–216. https://doi.org/10.1080/01446193.2018.1513162.

Toppinen A, Aaltio A, Lähtinen K, Jussila J, Toivonen R (2022) “It all depends on the project” – a business ecosystem in residential wooden multistory construction in Finland. Front Built Environ 8, article id 1046954. https://doi.org/10.3389/fbuil.2022.1046954.

Vainio T (2011) Building renovation – a new industry? In: Wamelink H, Geraedts R, Volker L (eds) Proceedings of the MISBE2011 – International Conference on Management and Innovation for a Sustainable Built Environment. ISBN 978-90-5269-395-8.