Pre-feasibility study of supply systems based on artificial drying of delimbed stem forest chips

Laitila J., Ahtikoski A., Repola J., Routa J. (2017). Pre-feasibility study of supply systems based on artificial drying of delimbed stem forest chips. Silva Fennica vol. 51 no. 4 article id 5659. https://doi.org/10.14214/sf.5659

Highlights

- With artificial drying and quick delivery, avoiding dry material losses of harvested timber, it could be possible to reduce the current costs of the prevailing procurement system based on natural drying of stored timber at roadside landings

- The maximum cost for the prospective drying process of fresh chips corresponds to, e.g., organization costs or stumpage price of delimbed stems.

Abstract

This study was aimed at determining the maximum cost level of artificial drying required for cost-efficient operation. This was done using a system analysis approach, in which the harvesting potential and procurement cost of alternative fuel chip production systems were compared at the stand and regional level. The accumulation and procurement cost of chipped delimbed stems from young forests were estimated within a 100 km transport distance from a hypothetical end use facility located in northern Finland. Logging and transportation costs, stumpage prices, tied up capital, dry matter losses and moisture content of harvested timber were considered in the study. Moisture content of artificially dried fuel chips made of fresh timber (55%) was set to 20%, 30% and 40% in the comparisons. Moisture content of fuel chips based on natural drying during storing was 40%. Transporting costs were calculated according to new higher permissible dimensions and weight limits for truck-trailers. The procurement cost calculations indicated that with artificial drying and by avoiding dry material losses of timber, it could be possible to reduce current costs of the prevailing procurement system based on natural drying of timber at roadside landings. The maximum cost level of artificial drying ranged between 1.2–3.2 € MWh–1 depending on the supply chain, moisture content and procurement volume of fuel chips. This cost margin corresponds to, e.g., organization, forwarding and transportation costs or stumpage price of delimbed stems.

Keywords

moisture content;

heating value;

procurement cost;

young forests;

dry matter loss

-

Laitila,

Natural Resources Institute Finland (Luke), Bio-based business and industry, P.O. Box 68, FI-80101 Joensuu, Finland

E-mail

juha.laitila@luke.fi

- Ahtikoski, Natural Resources Institute Finland (Luke), Management and Production of Renewable Resources, Paavo Havaksen tie 3, FI-90570 Oulu, Finland E-mail anssi.ahtikoski@luke.fi

- Repola, Natural Resources Institute Finland (Luke), Management and Production of Renewable Resources, Eteläranta 55, FI-96300 Rovaniemi, Finland E-mail jaakko.repola@luke.fi

- Routa, Natural Resources Institute Finland (Luke), Bio-based business and industry, P.O. Box 68, FI-80101 Joensuu, Finland E-mail johanna.routa@luke.fi

Received 17 February 2017 Accepted 22 August 2017 Published 15 September 2017

Views 158019

Available at https://doi.org/10.14214/sf.5659 | Download PDF

1 Introduction

Demand for fuel chips is often diachronic and shortages are usually buffered by means of stored material (Jirjis 1995; Rauch 2010; Filbakk et al. 2011; Laurila and Lauhanen 2012; Laurila 2013; Rauch 2013; Eriksson et al. 2014; Nurmi 2014). During the cold season of the year, the comminuting machinery and transportation equipment are in intensive use, while during the summer months, the problem is a lack of work (Laitila et al. 2010b). In contrast to other timber assortments, the quality of harvested material can be increased by storing because about half of the mass of a freshly felled tree is due to water (Hakkila 1989; Laurila 2013; Kanzian et al. 2016). Currently approximately 70% of timber logging is carried out while the soil is frozen, between October and April (Finnish statistical yearbook of forestry 2014).

Low moisture content increases the heating value of the fuel chips, as well as improves the boiler efficiency and reduces the transportation costs of produced chips (Röser et al. 2011). A disadvantage of natural drying is its slowness. Also, the effect of the natural drying is hardly predictable or controllable (Wolfsmayr and Rauch 2014). During storing, natural drying reduces moisture content, but on the other hand, biodegradation leads to loss of dry matter and loss of energy-rich extractives (Jirjis 1995; Filbakk et al. 2011; Laurila 2013; Rauch 2013; Nurmi 2014; Routa et al. 2015a). Together, these factors will determine the volumetric energy density (Nurmi 2014).

In natural drying, the environmental conditions are a very important parts of the drying process (Röser et al. 2011; Laurila 2013; Wolfsmayr and Rauch 2014; Erber et al. 2014; Pochi et al. 2015; Routa et al. 2015a; Routa et al. 2015b; Anisimov et al. 2017; Erber et al. 2017; ). Natural drying is most efficient during the spring and summer and covering the piles helps to maintain a lower moisture content during the winter (Röser et al. 2011). However during spring and summer storing periods the piles pose a risk of bark beetle infestation in adjacent coniferous stands (Kanzian et al. 2016). From the procurement point of view, an unfortunate disadvantage that accompanies storage is also tied to capital (Rauch 2013; Nurmi 2014). Artificial drying ensures a fast supply of fuel chips with the desired moisture content, but it introduces additional process and cost to the supply chain (Laurila et al. 2014; Wolfsmayr and Rauch 2014). Studies about the supply systems based on artificial drying of fuel chips have not been published recently.

The methods for artificial drying are thermal, cold-air and compression drying (Laurila 2013). In the past, artificial drying has not been used much in forest chip production, whereas the sawmilling and plywood industries, as well as pulp and paper industries, have used compression-based artificial drying for bark drying for decades (Alakangas 2005). Bark is softer and more wet than wood and presumably more appropriate for compression drying (Kärkkäinen 2007).

Manufacturing liquid biofuels in biorefineries and biomass gasification plants are subjects of increasing interest and can substantially increase the need for artificial drying of fresh forest chips in the future. In addition, laws mandating the physical dimensions of freight transport vehicles were changed on 1 October 2013 in Finland (Valtioneuvoston asetus 407/2013) and the new legislation enables higher gross weights as well as larger load capacities. It favours increasingly transport of fresh wood material (Laitila et al. 2016) and may also increase interest in artificial drying of forest chips in the generation of heat and in combined heat and power production, especially if waste heat streams can be used as a heat source for drying (Holmberg 2007; Rinne et al. 2014).

In the year 2015, Finnish heating and power plants consumed 18.3 million m³ of solid wood fuels, of which 10.1 million m³ were forest industry by-products and 7.3 million m³ comprised forest chips (Official Statistics of Finland 2016). A majority of the forest industry by-products were bark (6.9 m³ million) and sawdust (2.2 m³ million). The use of forest chips amounted to 4.8 million m³ in the combined heat and power production and to 2.5 million m³ in the generation of heat. Together with the forest chips consumed by farms and small-dwellings (0.7 million m3), the total consumption of forest chips reached 8.0 million m3 (Official Statistics of Finland 2016).

More than half or 3.9 million m3, of the forest chips were produced from small-diameter thinning wood originating from the management of young stands and 2.4 million m3 was produced from logging residue from final fellings. The use of stumps as raw material for forest chips amounted to 0.8 million m3 and large non-merchantable roundwood to 0.3 million m3 (Official Statistics of Finland 2016). In 2015, the proportions of fuel chip production methods including all forest chips raw materials were as follows: comminuting at roadside landings 53%, comminuting in terminals 31% and comminuting at the end use facilities 16% (Strandström 2016b).

1.1 Aim of the study

This study aimed to determine the maximum cost level of artificial drying required for cost-efficient operation by means of system analysis, in which the harvesting potential and procurement cost of alternative fuel chip production systems were compared at the stand and regional level. The accumulation and procurement cost of chips made from delimbed stems from young forests were estimated within a 100 km radius of a hypothetical end use facility located in Rovaniemi in northern Finland. The goal was to compare supply chains based on natural and artificial drying, whereby artificial drying costs have not been studied.

The comparisons of alternative supply chains started with organizing the timber purchasing and procurement activities, continued onto logging, transporting, chipping and delivery of fuel chips to the end user. Transporting costs were calculated according to new higher permissible dimensions and weight limits for truck-trailers. Stumpage prices, tied up capital, dry matter losses and moisture content of harvested timber were also considered in the study. The results were expressed as euros per solid cubic metre (€ m–3) or euros per megawatt hour (€ MWh–1). Moisture content of artificially dried fuel chips made of fresh timber was set to 20%, 30% and 40% in the comparisons. Moisture content of fuel chips based on natural drying during storing was assumed to be 40%.

2 Material and methods

2.1 Harvesting conditions and estimation of the potential supply of delimbed stems

The calculations of transportation distances of delimbed stems or chips produced from delimbed stems, transported via the existing road network to end use facility located in Rovaniemi, were based on GIS analysis and databases of major forest companies from the year 2000 (Ranta 2002; Ranta 2005). The transportation distance from municipality x to Rovaniemi was the average transportation distance from the clear felling stands of municipality x. The transporting distances varied between 5 and 100 kilometres (mean 79 km). The average forwarding distance was calculated in similar way for each municipality. Around Rovaniemi, the forwarding distances (Table 1) varied between 150–256 metres (mean 234 m). This existing stand data was evaluated to be valid for use in procurement cost calculations, since major changes in the composition of stands were not predicted.

| Table 1. The basic stand data estimates for delimbed stems around Rovaniemi. | |||

| Parameter | Average | Standard deviation | Unit |

| Forwarding distance | 234 | 24 | m |

| Transportation distance | 79 | 27 | km |

| The volume of stems harvested | 35 | 14 | dm3 |

| Removal, number of stems per hectare | 1385 | 565 | stems ha–1 |

| Removal, m3 of stems harvested per hectare | 43 | 13 | m3 ha–1 |

| The percentage of Scots pine of total removal | 43 | 44 | % |

| The percentage of Norway spruce of total removal | 14 | 25 | % |

| The percentage of birch of total removal | 41 | 39 | % |

| The percentage of other broadleaf trees of total removal | 2 | 12 | % |

The estimation of the technical harvesting potential of delimbed stems for energy in young forests in the province of Lapland was made based on the 8th National Forest Inventory (NFI8) and Multi-source National Forest Inventory (MS-NFI) data (Tomppo et al. 1998; Tomppo et al. 2001; Heikkilä et al. 2005). The NFI sample plot data contained information such as stand type (mineral or peat soil), habitat type, dominant tree species, diameter and height of trees, industrial roundwood volumes by tree species, etc. Resource calculations were made for the young thinning stands (dominant height >7 m, dbh 8–16 cm) needing thinning within the first five-year period. For each of the sample plots selected, the removal of delimbed stems was calculated by simulating thinning in accordance with silvicultural guidelines (Metsätalouden kehittämiskeskus Tapio 2006) and only stems of more than 4 cm in diameter at 1.3 m in height (dbh) were considered.

The area that an NFI sample plot represents in a certain municipality and stand development class was calculated according to the methodology described by Laitila et al. (2010a). The minimum yield of delimbed stems was set to be 25 m3 ha–1 and average size of delimbed stems was greater than 20 litres on selected stands. The maximum allowable yield of industrial roundwood was set to be 40 m3 ha–1 and stands having a higher accumulation were allocated to forest industry chemical pulping instead of pure energy use. The potential supply of delimbed stems were first estimated as a solid volume (m3 year–1) and then according to energy content (MWh year–1). The basic stand data estimates and wood properties of delimbed stems or chips produced from delimbed stems are presented in Table 1 and 2. In this connection, it should be emphasized that the procurement cost of fuel chips around Rovaniemi was strongly dependent on the transportation distances and the characteristics of the sample plots.

| Table 2. The wood properties of delimbed stems or chips produced from delimbed stems as a function of drying method and moisture content. | |||

| Material type | Moisture content, % | Average weight, kg m–3 | Standard deviation |

| Delimbed stems as fresh | 55 | 950 | 82 |

| Delimbed stems after storing | 40 | 662 | 57 |

| Artificially dried fuel chips | 40 | 710 | 61 |

| Artificially dried fuel chips | 30 | 609 | 52 |

| Artificially dried fuel chips | 20 | 533 | 18 |

The net calorific value of delimbed stems (at constant pressure) as received was calculated from a net calorific value of the dry and ash-free material, according to the following equation (Alakangas 2005):

where:

qp,net,ar = is the net calorific value (at constant pressure) as received (MJkg–1)

qp,net,daf = is the net calorific value (at constant pressure) on a dry and ash-free basis (MJkg–1)

Mar = is the moisture content as received

Ad = is the ash content on a dry basis (0%)

0.02443 = is the correction factor of the enthalpy of vaporization at 25 °C

Basic densities (kg m–3) for delimbed stems were used according to Hakkila (1978) by tree species. Correspondingly, tree species-specific net calorific values of dry matter (MJ kg–1) were used according to Nurmi (1993). Moisture contents of 20%, 30% and 40% were used for artificially dried stem wood chips and a moisture content of 40% (Table 2) for delimbed stems stored at roadside landings (Hakkila 1989; Nurmi and Hillebrand 2007; Laurila and Lauhanen 2012; Nuutinen et al. 2014). The dry matter loss of delimbed stems during nine months of storage was set to be 6.75% (Mäkelä et al. 2000). The validity of the nine month storage time was verified via discussions with wood-fuel managers of procurement organizations and power plants.

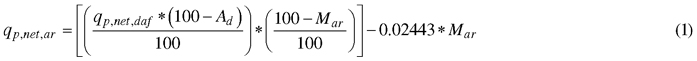

2.2 Productivity and cost parameters of the procurement system

Productivity and cost parameters were linked with above-described forest and GIS data. Costs of production stages were first defined per solid volume (€ m–3), and in final summing the costs were converted into euros per megawatt hour (€ MWh–3). The production stages of supply chains and forest resources of this study are demonstrated in Fig. 1. It was assumed that harvested delimbed stems were drying during the nine-month storing period to the moisture content of 40% at the roadside landing or produced fresh chips were dried artificially to the moisture content of 20%, 30% or 40% at the end use facility or at the terminal. Seasons were not considered and thus the moisture content of stored timber was 40% regardless of the season. The storage rotation of the fresh timber (55%) was one month from logging to the chipping and artificial drying. For the production of fuel chips there were three options: 1) chipping at the roadside landing, 2) chipping at the end use facility, or 3) chipping at the terminal (Fig. 1).

Fig. 1. The supply chains and forest resources of this study by the main work stages. View larger in new window/tab.

The organization cost of 3.2 € m–3 (Table 3) was set as a constant for all supply chains in this study and it corresponds to the average organization cost of industrial roundwood procurement in Finland (Strandström 2016a). The 5.5 € m–3 stumpage price of delimbed stems was based on price statistics (Volumes and prices in the energy wood trade 2016). A conventional harvester-forwarder chain was used in logging. The productivity of multi-stem cutting was based on the study of Laitila and Väätäinen (2013). Forwarding productivity was calculated by means of the model by Kuitto et al. (1994). The payload (Table 3) was set in line with the work of Laitila et al. (2010a). The gross effective time (E15h) coefficients (Table 3) for multi-stem cutting and forwarding were based on research by Jylhä et al. (2010). The total length of the strip road network at the thinning stand was assumed to be 600 m ha–1, based on an average strip road spacing of 20 m (Niemistö 1992).The hourly cost data for logging machinery, acquired from literature (Laitila et al. 2015), are described in Table 3.

| Table 3. The productivity and cost parameters for the supply chains. MC = moisture content. | |

| The cost of organization, € m–3 | 3.2 |

| The stumpage price of delimbed stems, € m–3 | 5.5 |

| Hourly cost of the harvester equipped with multi-stem devices, € E15h–1 | 102.3 |

| Gross effective time (E15h) coefficient for multi-stem cutting | 1.39 |

| Hourly cost of the forwarder, € E15h–1 | 81.0 |

| Payload of the forwarder, m3 | 9.0 |

| Gross effective time (E15h) coefficient for forwarding | 1.3 |

| The cost of chipping at the terminal or end use facility, € m–3 | 5.5 |

| The cost of chipping at the roadside landing, € m–3 | 8.0 |

| Payload of the 76-tonne timber truck with fresh timber (MC 55%), m3 | 47.6–60.6 |

| Payload of the 76-tonne timber truck with stored timber (MC 40%), m3 | 63.8 |

| Payload of the 69-tonne chip truck with fresh timber (MC 55%), m3 | 38.5–48.9 |

| Payload of the 69-tonne chip truck with stored timber (MC 40%), m3 | 55.2–63.0 |

| Payload of the 76-tonne chip truck in the chip deliveries from the terminal (MC 20–40%), m3 | 61.1–63.0 |

In this study a static spreadsheet-based calculation approach was applied, which meant that the fluctuation of interactions in loading or chipping, transporting and unloading at the end-use-facility were not considered. Delimbed stems (the length 5 metres) were transported to the end use facility or terminal using a conventional 76-tonne timber truck, assuming a maximum permissible payload of 63.8 m3 (solid) and 24-tonne empty weight (Korpilahti and Koskinen 2013). Chips produced at the roadside landings were transported with a 69-tonne modern truck-trailer equipped with steering axles at the rear end of the trailer (ETS). The truck-trailer unit had a 157.4 m3 load space and 27-tonne empty weight (Laitila et al. 2016). Chips produced at the terminal were transported in a standard 76-tonne truck-trailer having a 157.4 m3 load space and 26-tonne empty weight (Laitila et al. 2016).

The transportation time consisted of driving time and terminal time. Loading, unloading, waiting and auxiliary time were included in the terminal time estimations. The time consumption of driving, with a full load and empty, was calculated as a function of transportation distance, according to the speed functions of Nurminen and Heinonen (2007). The truck-trailers were assumed to drive to the destination fully loaded and return empty to the starting point and the same transporting distance was used for driving both with and without a load.

When needed the payloads were restricted either by the load carrying or load space capacity of the truck-trailer (e.g. Windisch et al. 2015; Laitila et al. 2016). The degree of filling and permissible payload was calculated for each stand as a function of basic densities of tree species, dry matter losses of storing (6.75%) moisture content (40% or 55%) and solid content percentage (40%) of wood chips (Table 3). The payload of the 76-tonne timber truck varied from 47.6 to 60.6 m3 (mean 55.2 m3) when transporting fresh delimbed stems. With stored timber the payload was the maximum permissible solid volume (63.8 m³) in all stands. The payloads of chips produced at the roadside landings varied within stands in the range of 38.5–48.9 m3 (mean 44.6 m3) for fresh timber and 55.2–63.0 m3 (mean 61.0 m3) for stored timber. The weight of chips produced at the terminal did not exceed the load carrying capacity of the 76-tonne truck-trailer and the payload was thus the maximum permissible (63.0 m3) in all delivered loads, excluding artificially dried chips to the moisture content of 40%. In that case, payload varied in range of 61.1–63.0 m3 (mean 62.7 m3).

When producing chips at the roadside landings, terminal or end use facility (Fig. 1), the chipper’s direct chipping productivity was set to be 68.4 m3 E15h–1 (Föhr et al. 2010; Kärhä et al. 2011b; Laitila and Routa 2015). In addition, a fixed value of 25 minutes was assumed for the indirect loading time of truck-trailers at a roadside landing, which is the time required for manoeuvring trucks and trailers or a chipper during loading (Windisch et al. 2015). Thus the chipping productivity and cost were 47.1 m3 E15h–1 and 8.0 € m–3, respectively, when chips were produced at roadside landings and 5.5 € m–3 when chipping was done centrally at the terminal or end use facility (Table 3 and 4).

| Table 4. Hourly cost details of the truck-mounted chipper capable of operating at roadside landings, terminals and end use facilities. | |

| Purchase price of truck-mounted chipper, € | 520 000 |

| Annual depreciation of purchase price, % | 17 |

| Lifespan, years | 7 |

| Productive machine hours per year, E15h–1 | 805 |

| Salvage value, € | 141 107 |

| FIXED COSTS: | |

| Depreciation, € a–1 | 54 128 |

| Interest, € a–1 | 17 881 |

| Insurance, € a–1 | 14 128 |

| Administration, € a–1 | 7500 |

| LABOUR COSTS: | |

| Annual working time, h | 2237 |

| Average wage for a worker, € h–1 | 18 |

| Indirect wage costs, % | 68 |

| Wage costs total, € a–1 | 67 640 |

| OPERATING COSTS: | |

| Fuel cost, € a–1 | 96 173 |

| Fuel price, € litres–1 | 0.9 |

| Blade cost, € a–1 | 10 146 |

| Lubricants | 2805 |

| Service and maintenance cost, € a–1 | 18 583 |

| Risk and profit margin (5%), € a–1 | 14 449 |

| TOTAL COSTS: | 303 433 |

| Operating hour cost for chipping, € E15h–1 (VAT 0%) | 376.8 |

The loading time of chips at the roadside landings was linked to the chipping productivity of the chipper and permissible payload of the 69-tonne truck-trailer. Loading time of chips at the terminal with a wheel loader was 24 minutes per load (Virkkunen et al. 2016) and loading cost was 1.9 € m–3 (Varis 2014). The transporting distance from the terminal to the end use facility was 20 kilometres. The loading time of delimbed stems was estimated to be 50 minutes at the roadside landing, and the unloading time was 37 minutes per load (Laitila et al. 2009; Laitila and Väätäinen 2012). The unloading time of chips at the end use facility was assumed to be 15 minutes per load. The hourly cost data of truck-trailers for driving and terminal time are described in Table 5.

| Table 5. Hourly cost details of the truck-trailers. | |||

| 69-tonne ETS chip truck-trailer | 76-tonne timber truck-trailer | 76-tonne chip truck-trailer | |

| Purchase price of truck, € | 166 300 | 193 800 | 166 300 |

| Annual depreciation of purchase price, % | 20 | 20 | 20 |

| Lifespan, years & kilometres | 10 & 756 830 | 10 & 756 830 | 7 & 657 842 |

| Salvage value, € | 17 856 | 20 809 | 34 876 |

| Purchase price of timber loader | - | 70 000 | - |

| Annual depreciation of purchase price, % | - | 20 | - |

| Lifespan, years | - | 10 | - |

| Salvage value, € | - | 7516 | - |

| Purchase price of trailer, € | 185 500 | 66 000 | 171 900 |

| Annual depreciation of purchase price, % | 25 | 25 | 25 |

| Lifespan, years & kilometres | 10 & 756 830 | 10 & 756 830 | 7 & 657 842 |

| Salvage value, € | 10 446 | 3717 | 22 946 |

| FIXED COSTS: | |||

| Depreciation, € a–1 | 32 350 | 29 776 | 40 054 |

| Interest, € a–1 | 7212 | 7133 | 8950 |

| Insurance, € a–1 | 8500 | 5500 | 8500 |

| Administration, € a–1 | 8443 | 8524 | 8429 |

| LABOUR COSTS: | |||

| Annual working time, h | 4320 | 4320 | 4320 |

| Average wage for a worker, € h–1 | 18 | 18 | 18 |

| Indirect wage costs, % | 68 | 68 | 68 |

| Wage costs total, € a–1 | 130 637 | 130 637 | 130 637 |

| OPERATING COSTS: | |||

| Fuel price, € litres–1 | 1.15 | 1.15 | 1.15 |

| Fuel consumption, litres100 km–1 | 62 | 63 | 66 |

| Fuel cost, € a–1 | 53 962 | 54 832 | 71 545 |

| Number of truck wheels and tyre price, € pcs–1 | 12*725 | 12*725 | 12*725 |

| Number of trailer wheels and tyre price, € pcs–1 | 10*450 | 20*450 | 18*450 |

| Service life of tyres, km | 120 000 | 120 000 | 120 000 |

| Number of remoulds during service life | 2 | 2 | 2 |

| Remould price, € pcs–1 | 300 | 300 | 300 |

| Tyre cost, € a–1 | 5947 | 8312 | 9733 |

| Service and maintenance cost, € a–1 | 32 000 | 32 582 | 32 000 |

| Risk and profit margin (5%), € a–1 | 13 953 | 13 865 | 15 492 |

| TOTAL COSTS: | 293 003 | 291 159 | 325 340 |

| Operating hour cost for terminal time, € E15h–1 (VAT 0%) | 46.5 | 45.2 | 49.1 |

| Operating hour cost for driving time, € E15h–1 (VAT 0%) | 67.8 | 67.4 | 75.3 |

The cost of capital applied to storages was calculated for each stand according to the following equation:

![]()

where:

r = is the amount of interest (€ m–3)

k = capital employed on stumpage price of delimbed stems and cost of logging and organization (€ m–3)

p = the interest percentage (5%)

t = storing time in days (30 or 274 days)

2.3 The hourly cost calculations

The operating costs (excluding value-added tax) of the truck-mounted chipper and truck-trailers (Table 4 and 5) were calculated per gross effective hour (E15h) and the costs are presented in euros (€).The average purchase prices and technical details were acquired from the dealers and the calculation values for labour costs, fuel, insurance fees, repairs and service expenses were obtained from Koneyrittäjien Liitto ry (the Trade Association of Finnish Forestry and Earth Moving Contractors) and Metsäalan Kuljetusyrittäjät ry (the Association of Forest Industry Road Carriers).

The costs included both time-dependent costs (e.g. capital depreciation, interest expenses, labour costs, insurance fees, and administration expenses) and variable operating expenses (e.g. fuel, repairs, service, and machine transfers). In addition to the annual total cost, 5% was added to take into account the risk of entrepreneurship. Capital costs were calculated using an interest rate of 5%. For the truck transportation the hourly cost was divided between driving and terminal times. When calculating the terminal time cost of the truck-trailer, the fuel, oil and service costs were excluded from the total costs.

The lifespan of the 76-tonne chip truck-trailer was shorter (7 years) and annual driving kilometres (93 977 km) longer than of the others because it was expected that when transporting chips from the terminal the driving routes as well as the loading and unloading times are much more constant and predictable compared to chip or timber deliveries from roadside landings. Terminal enables better beforehand planning of transportation tasks (e.g. multi-point transport of different raw materials) and thus better year-round employment compared to truck-trailers operating geographically fragmented roadside landings.

3 Results

3.1 Harvesting potential of fuel chips

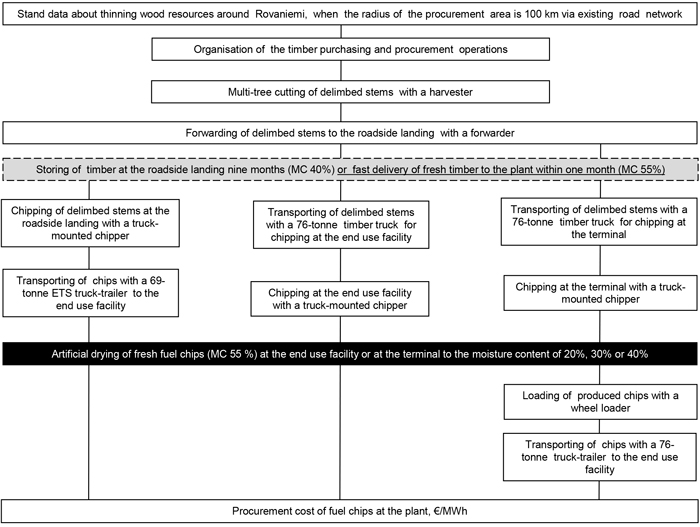

The availability analysis indicated that around Rovaniemi the technical harvesting potential of delimbed stems was 162 905 m3 per year. Based on assumptions, the energy content of fuel chips produced from delimbed stems was 317 232–359 874 MWh depending on the moisture content and dry material losses of delimbed stems due to storage (Fig. 2). The average energy content of fuel chips, produced from stored timber having a moisture content of 40%, was 1.94 MWh m–3. The average energy content of artificially dried fuel chips produced from fresh timber were 2.09 MWh m–3, 2.15 MWh m–3 and 2.2 MWh m–3, when the moisture contents were set to 40%, 30% and 20%, respectively.

Fig. 2. The technical harvesting potential of delimbed stems around Rovaniemi, when the moisture content of produced chips is 20 %, 30% or 40%.

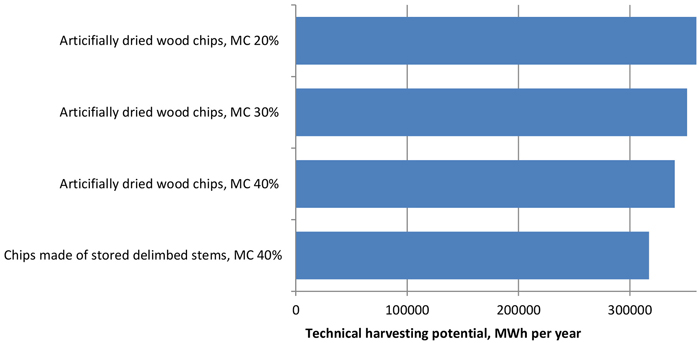

3.2 Cost structure of fuel chips

The procurement cost of fuel chips based on average values in the procurement area of Rovaniemi, was 41.10–45.06 € m–3 at the plant depending on the supply chain (Fig. 3), when the technical harvesting potential of delimbed stems was 162 905 m3 per year. The supply chain based on chipping at the end use facility was the most cost efficient, while the procurement cost of supply chains based on chipping at the roadside landing or at the terminal were at the same level, when costs were expressed as euros per solid cubic metre (€ m–3). The logging costs were 50–55 % of the total procurement costs (Fig. 3).

Fig. 3. The procurement cost structure of the supply chains and raw material options of this study. Costs are based on average values in the procurement area of Rovaniemi (cf. Table 1, 2 and 3).

The cost structures of supply chains based on artificial or natural drying were similar in the procurement area of Rovaniemi (Fig. 3). The cost differences were due to the transporting and interest costs. Natural drying and dry matter losses during storing enabled bigger payloads and 0.61–1.26 € m–3 lower transport cost, but interest cost were on average 1.04 € m–3 higher due to storing (Fig. 3). In the supply chains based on chipping at the end use facility or at the terminal, the lower transporting costs did not compensate the higher interest costs and thus the procurement costs of fresh timber were slightly lower compared to stored timber (Fig. 3). Whereas, in the supply chain based on chipping at the roadside landing (Fig. 3), the transport cost saving exceeded interest cost expressed as euros per solid cubic metre (€ m–3) and the procurement cost of stored timber was lower compared to procurement of fresh timber (Fig. 3).

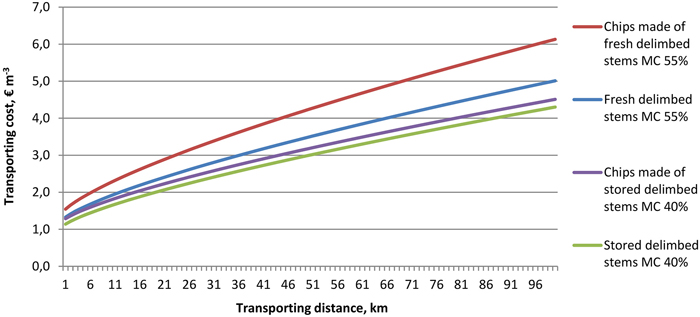

Depending on transporting distance (1–100 km), transporting costs of chips made of fresh timber (55%) and produced at roadside landings were 0.26–1.62 € m–3 higher compared to chips made of stored timber having a moisture content of 40% (Fig. 4) with a 69-tonne truck-trailer. Correspondingly transporting costs for fresh delimbed stems with a timber truck were 0.19–0.71 € m–3 higher compared to transporting stored timber. In the cost comparison, the solid cubic weights of fresh and stored timber were 950 kg m–3 and 662 kg m–3, respectively (Table 2), and transportation was carried out using the conventional 76-tonne timber truck and the 69-tonne modern chip truck-trailer equipped with steering axles at the rear end of the trailer (ETS). Due to smaller payload the transporting costs of fresh timber rose more steeply compared to stored timber as a function of transporting distance (Fig. 4).

Fig. 4. Transporting costs of delimbed stems and chips as a function of transporting distance, when the moisture content (MC) is either 40% or 55%.

3.3 Procurement cost of fuel chips

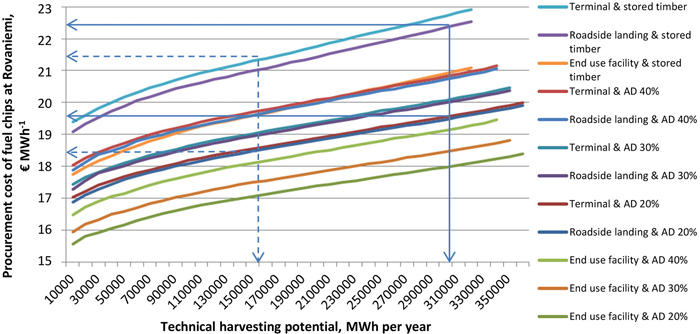

The procurement cost of fuel chips were calculated applying the above-described forest and GIS data and productivity and cost parameters for a hypothetical plant located in Rovaniemi. The cumulative accumulation of fuel chips at marginal procurement cost was calculated for alternative supply chains, storing options and moisture contents. The cost at the end use facility was expressed as euros per megawatt hour (€ MWh–1), according to fuel-property parameters of delimbed stems (Fig. 5). The supply chain based on chipping at the end use facility was the most cost efficient procurement system, while the procurement costs of supply chains based on chipping at the roadside landing or at the terminal were at the same level (Fig. 5).

Fig. 5. The procurement cost of fuel chips around Rovaniemi when using alternative supply chains and alternative moisture contents and storing options for produced chips. AD = artificial drying.

The procurement cost calculations indicated that with artificial drying and quick delivery by avoiding dry material losses of harvested timber, it could be possible to reduce current costs of the prevailing procurement system based on natural drying of stored timber at roadside landings (Fig. 5). The cost saving potential gained by artificial drying rose as a function of procurement volume, which implies the possibility of economies of scale (e.g. Begg et al. 2005). However the savings in the procurement costs must off-set the additional costs caused by artificial drying and handling of fuel chips at the terminal or at the end use facility.

In this case, the cost of artificial drying compared to conventional fuel chip procurement can have a maximum of 1.8–2.7 € MWh–1 when the moisture content of produced chips was 30% and 2.2–3.2 € MWh–1 when the moisture content was 20% (Fig. 5), depending on the supply chain and procurement volume. Correspondingly, the cost margin was 1.2–1.9 € MWh–1 for the artificially dried chips having a moisture content of 40%.

Between supply chains the improvement potential gained by prospective artificial drying was rather similar (Fig. 5). For example, with annual procurement of 150 000 MWh the break-even cost (i.e. equalling the cost saving potential by artificial drying) was 2.5 € MWh–1 when 20% moisture content of produced chips was applied for supply chains based on chipping at the end use facility or at the roadside landing. For a supply chain based on terminal chipping, the break-even cost was 2.7 € MWh–1 (Fig. 5: dotted-line arrows). Further, with annual procurement of 300 000 MWh the break-even cost was 2.9 € MWh–1 for supply chains based on chipping at the end use facility or at the roadside landings (Fig. 5: straight-line arrows) and 3.2 € MWh–1 for supply chain based on chipping at the terminal (Fig. 5).

4 Discussion

The homogeneity of moisture content is one of the most important fuel characteristics from the end user’s point of view. In natural drying, fuel wood is often kept in storage too long in order to guarantee that it is dry enough (Nurmi 2014; Routa et al. 2015b). This increases storage levels and due to that, also the capital costs of procurement and dry matter losses of stored material increase (Nurmi 2014; Routa et al. 2015b). However the moisture content of fuel wood after one year of storing is typically just 10–15% lower than the moisture content of fresh timber (Hakkila 1989; Nurmi and Hillebrand 2007; Laurila 2013) and moisture content of delivered wood chips inevitably fluctuates because of constantly changing drying and storage conditions. This may make storage management complicated especially if timber stacks are distributed at many roadside landings around the end-use-facility. When the procurement is based on fresh timber, storage levels are lower and the same supply chain management applications as those used in purchasing, harvesting, storing and transporting industrial wood can be used.

Dry matter loss during storage was calculated to be 0.75% per month in this, which is an average value, based on storing trials of birch (Betula spp.), Norway spruce (Picea abies (L.) H. Karst.) and Scots pine (Pinus sylvestris L.) pulpwood (Mäkelä et al. 2000). Tree species, material characteristics, moisture, temperature, size and shape of the energy-wood pile, amount of nutrients, and oxygen content of the pile combine to affect the microbial activity and deterioration of energy wood (Jirjis 1995; Nurmi 1999; Pettersson and Nordfjell 2007; Nurmi 2014; Routa et al. 2015a). In this study trees from young stands were harvested as delimbed, offering stem wood feedstock devoid of nutrient-rich needles and branches, which is an obvious benefit when attempting to avoid dry matter losses compared to harvesting systems based on harvesting with branches (Bergström et al. 2010; Bergström and Di Fulvio 2014a; Bergström and Di Fulvio 2014b; Nuutinen and Björheden 2015; Hanzelka et al. 2016; Nuutinen et al. 2016).

Deterioration of fuel wood due to storing also has a negative impact on particle size distribution, thus increasing the unwanted incidence of fines (Pochi et al. 2015). In addition, winter storage results often in rewetting of fuel wood, which may cancel out any benefits obtained during the drying period (Jirjis 1995). Covering the storage piles at roadside landings is essential to prevent remoistening in autumn and winter, but covering piles requires extra work leading to increased costs. The cost of covering a pile of delimbed stems is about 0.4 € MWh–1 in Finnish conditions (Hillebrand and Nurmi 2004). When drying, wood also becomes harder and this may lead to decreased chipping productivity (Pochi et al. 2015). However the use of new sharp knives preserves chipping productivity and also affects chip quality (Spinelli et al. 2014; Laitila and Routa 2015).

Considerable benefits for combustion, such as increased boiler efficiency, lower flue gas emissions and improved boiler operations can be achieved with dry fuel chips, compared to fuels with high moisture, especially in small- and medium-size plants (Ranta 2002). To avoid the additional work and extra handling of chips, feeding of the chip dryer is considered to be a direct part of unloading the chips. The drying unit can be, e.g., of batch or silo type or alternatively a belt dryer (Brammer and Bridgwater 1999). Utilizing low-grade, waste heat – of which large amounts are available from many process industries – could significantly reduce energy consumption and the profitability of artificial drying (Li et al. 2011; Holmberg 2007; Rinne et al. 2014). In winter, the surface of freshly harvested timber is often icy or snowy, which can raise the moisture content of wood chips significantly. The weight of ice and snow might also decrease payloads of fresh timber or chips in truck transportation.

The results indicated that the maximum cost level of artificial drying ranged between 1.2–3.2 € MWh–1 depending on the supply chain, moisture content and procurement volume of fuel chips (Fig. 5). This cost margin corresponds more or less to, e.g., organization costs or stumpage price – both being relevant in absolute terms. Thus, it would be intriguingly revealing to conduct an experiment which demonstrates in practice the actual costs of artificial drying, because state-of-the-art information is not available. Only after this information is available can the financial viability of artificial drying determined. However, this merits another, separate study since this work merely introduces the numerical boundaries for profitability as a function of technical harvesting potential in one geographic region. Eventually, it is a question of whether to invest in artificial drying or to stick with the traditional procurement practices and bind capital to large-scale storing at roadside landings. The answer depends on the customers, particularly their ability and willingness to pay for fuel chips with a homogeneous moisture content.

Acknowledgements

The authors gratefully acknowledge financial support from the Local Divided Bioenergy as Solution-project (LODIBI) and Strategic Research Consortium Project FORBIO (3500010200), funded by the Strategic Research Council of Academy of Finland.

References

Alakangas E. (2005). Properties of wood fuels used in Finland – BIOSOUTH-project. Technical Research Centre of Finland (VTT). Project report PRO/P2030/05. 90 p. + app. 10 p.

Anisimov P., Onuchin E., Vishnevskaja M. (2017). Modeling pine and birch whole tree drying in bunches in the cutting area. Croatian Journal of Forest Engineering 38(1): 11–17.

Begg D., Fischer S., Dornbusch R. (2005). Economics. 8th ed. McGraw-Hill Education (UK) Limited. 674 p.

Bergström D., Di Fulvio F. (2014a). Comparison of the cost and energy efficiencies of present and future biomass supply systems for young dense forests. Scandinavian Journal of Forest Research 29(8): 793–812. https://doi.org/10.1080/02827581.2014.976590.

Bergström D., Di Fulvio F. (2014b). Evaluation of a novel prototype harvester head in early fuel-wood thinnings. International Journal of Forest Engineering 25(2): 156–170. https://doi.org/10.1080/14942119.2014.945697.

Bergström D., Nordfjell T., Bergsten U. (2010). Compression processing and load compression of young scots pine and birch trees in thinnings for bioenergy. International Journal of Forest Engineering 21(1): 31–39.

Brammer J.G., Bridgwater A.V. (1999). Drying technologies for an integrated gasification bio-energy plant. Renewable and Sustainable Energy Reviews 3(4): 243–289. https://doi.org/10.1016/S1364-0321(99)00008-8.

Erber G., Routa J., Kolström M., Kanzian C., Sikanen L., Stampfer K. (2014). Comparing two different approaches in modeling small diameter energy wood drying in logwood piles. Croatian Journal of Forest Engineering 35(1): 15–22.

Erber G., Holzleitner F., Kastner M., Stampfer K. (2017). Impact of different time interval bases on the accuracy of meteorological data based drying models for oak (Quercus L.) logs stored in piles for energy purposes. Croatian Journal of Forest Engineering 38(1): 1–9.

Eriksson A., Eliasson L., Jirjis R. (2014). Simulation-based evaluation of supply chains for stump fuel. International Journal of Forest Engineering 25(1): 23–36. https://doi.org/10.1080/14942119.2014.892293.

Filbakk T., Høibø O.A., Dibdiakova J., Nurmi J. (2011). Modelling moisture content and dry matter loss during storage of logging residues for energy. Scandinavian Journal of Forest Research 26(3): 267–277. https://doi.org/10.1080/02827581.2011.553199.

Finnish statistical yearbook of forestry (2014). Official Statistics of Finland. Finnish Forest Research Institute. 428 p. ISBN 978-951-40-2506-8. http://www.metla.fi/julkaisut/metsatilastollinenvsk/. [In Finnish].

Föhr J., Karttunen K., Ranta T. (2010). Energiapuun tienvarsihaketus. [Chipping of energy wood at the roadside landing]. In: Karttunen K., Föhr J., Ranta T. (eds.). Energiapuuta Etelä-Savosta. Lappeenrannan teknillinen yliopisto, Tutkimusraportti 7: 71–79. [In Finnish].

Hakkila P. (1978). Pienpuun korjuu polttoaineeksi. [Harvesting small-sized wood]. Folia Forestalia 342. 38 p. [In Finnish with English summary].

Hakkila P. (1989). Utilization of residual biomass. Springer series in wood science. Springer-Verlag. 568 p.

Hanzelka N.C., Bolding M.C., Sullivan J., Barrett S.M. (2016). Productivity and costs of utilizing small-diameter stems in a biomass-only harvest. International Journal of Forest Engineering 27(1): 43–52. https://doi.org/10.1080/14942119.2015.1135615.

Heikkilä J., Laitila J., Tanttu V., Lindblad J., Sirén M., Asikainen A., Pasanen K., Korhonen K.T. (2005). Karsitun energiapuun korjuuvaihtoehdot ja kustannustekijät. [Harvesting alternatives and cost factors of delimbed energy wood]. Working Papers of the Finnish Forest Research Institute 10. 56 p. [In Finnish]. http://urn.fi/URN:ISBN:951-40-1964-4.

Hillebrand K., Nurmi J. (2004). Nuorista metsistä korjatun energiapuun kuivatus ja varastointi. [Drying and storing of energy wood harvested from young stands]. Projektiraportti PRO2/P6014/04. VTT Prosessit. 27 p. [In Finnish].

Holmberg H. (2007). Biofuel drying as a concept to improve the energy efficiency of an industrial CHP plant. Doctoral Dissertation. TKK Dissertationes 63. http://lib.tkk.fi/Diss/2007/isbn9789512286492/.

Jirjis R. (1995). Storage and drying of wood fuel. Biomass and Bioenergy 9(1–5): 181–190. https://doi.org/10.1016/0961-9534(95)00090-9.

Jylhä P., Dahl O., Laitila J., Kärhä K. (2010). The effect of supply system on the wood paying capability of a kraft pulp mill using Scots pine harvested from first thinnings. Silva Fennica 44(4): 695–714. https://doi.org/10.14214/sf.454.

Kanzian C., Kuhmaier M., Erber G. (2016). Effects of moisture content on supply cost and CO2 emissions for an optimized energy wood supply network. Croatian Journal of Forest Engineering 37(1): 51–60.

Kärhä K., Hautala A., Mutikainen A. (2011). Heinola 1310 ES hakkuutähteiden ja pienpuun haketuksessa. [Chipping of logging residues and whole trees with Heinola 1350 ES drum chipper]. Metsätehon tuloskalvosarja 9/2011. 33 p. [In Finnish].

Kärkkäinen M. (2007). Puun rakenne ja ominaisuudet. [Wood structure and properties]. Metsälehti kustannus. 468 p. [In Finnish].

Kuitto P.-J., Keskinen S., Lindroos J., Oijala T., Rajamäki J., Räsänen T., Terävä J. (1994). Puutavaran koneellinen hakkuu ja metsäkuljetus. [Mechanized cutting and forest haulage]. Metsäteho Report 410. 38 p. [In Finnish].

Korpilahti A., Koskinen O.H. (2013). Uusien mittojen ja massojen mukaiset puutavara-autot. [The timber trucks of the new dimensions and gross weights]. Metsätehon kalvosarja 2/2013. 33 p. [In Finnish].

Laitila J., Routa J. (2015). Performance of a small and a medium sized professional chippers and the impact of storage time on Scots pine (Pinus sylvestris) stem wood chips characteristics. Silva Fennica 49(5) article 1382. https://doi.org/10.14214/sf.1382.

Laitila J., Väätäinen K. (2012). Truck transportation and chipping productivity of whole trees and delimbed energy wood in Finland. Croatian Journal of Forest Engineering 33(2): 199–210.

Laitila J., Väätäinen K. (2013). The cutting productivity of the excavator-based harvester in integrated harvesting of pulpwood and energy wood. Baltic Forestry 19(2): 289–300.

Laitila J., Kärhä K., Jylhä P. (2009). Time consumption models and parameters for off- and on-road transportation of whole-tree bundles. Baltic Forestry 15: 105–114.

Laitila J., Heikkilä J., Anttila P. (2010a). Harvesting alternatives, accumulation and procurement cost of small-diameter thinning wood for fuel in Central-Finland. Silva Fennica 44(3): 465–480. https://doi.org/10.14214/sf.143.

Laitila J., Leinonen A., Flyktman M., Virkkunen M., Asikainen A. (2010b). Metsähakkeen hankinta- ja toimituslogistiikan haasteet ja kehittämistarpeet. [Challenges and development needs of forest chips procurement and delivery logistics]. VTT Tiedotteita 2564. 143 p. [In Finnish].

Laitila J., Ranta T., Asikainen A., Jäppinen E., Korpinen O.-J. (2015). The cost competitiveness of conifer stumps in the procurement of forest chips for fuel in Southern and Northern Finland. Silva Fennica 49(2) article 1280. https://doi.org/10.14214/sf.1280.

Laitila J., Asikainen A., Ranta T. (2016). Cost analysis of transporting forest chips and forest industry by-products with large truck-trailers in Finland. Biomass and Bioenergy 90: 252–261. https://doi.org/10.1016/j.biombioe.2016.04.011.

Laurila J. (2013). Moisture content, weight loss and potential of energy wood in South and Central Ostrobothnia regions in western Finland. Dissertationes Forestales 167. https://doi.org/10.14214/df.167.

Laurila J., Lauhanen R. (2012). Weight and volume of small-sized whole trees at different phases of the supply chain. Scandinavian Journal of Forest Research (27)1: 46–55. https://doi.org/10.1080/02827581.2011.629621.

Laurila J., Havimo M., Lauhanen R. (2014). Compression drying of energy wood. Fuel processing technology 124: 286–289. https://doi.org/10.1016/j.fuproc.2014.03.016.

Li H., Chen Q., Zhang X., Finney K.N., Sharifi V.N., Swithenbank J. (2011). Evaluation of a biomass drying process using waste heat from process industries: a case study. Applied Thermal Engineering 35: 71–80. https://doi.org/10.1016/j.applthermaleng.2011.10.009.

Mäkelä M., Korhonen K., Lipponen K. (2000). Varastoinnin vaikutus kuitupuuhun. [The impact of storing to the wood properties of pulpwood]. Metsätehon raportti 91 B. 37 p. [In Finnish].

Metsätalouden kehittämiskeskus Tapio (2006). Hyvän metsänhoidon suositukset. [Recommendations for good silviculture]. Forestry Development Centre Tapio. 100 p.

Niemistö P. (1992). Runkolukuun perustuvat harvennusmallit. [Thinning models based on the number of stems]. Finnish Forest Research Institute, Research Papers 432. 18 p. [In Finnish]. http://urn.fi/URN:ISBN:951-40-1249-6.

Nurmi J. (1993). Heating values of the above ground biomass of small-sized trees. Acta Forestalia Fennica 236. https://doi.org/10.14214/aff.7682.

Nurmi J. (1999). The storage of logging residue for fuel. Biomass Bioenergy 17(1): 41–47. https://doi.org/10.1016/S0961-9534(99)00023-9.

Nurmi J. (2014). Changes in volumetric energy densities during storage of whole-tree feed stocks from silvicultural thinnings. Biomass and Bioenergy 61: 114–120. https://doi.org/10.1016/j.biombioe.2013.12.001.

Nurmi J., Hillebrand K. (2007). The characteristics of whole-tree fuel stocks from silvicultural cleanings and thinnings. Biomass & Bioenergy 31(6): 381–392. https://doi.org/10.1016/j.biombioe.2007.01.010.

Nurminen T., Heinonen J. (2007). Characteristics and time consumption of timber trucking in Finland. Silva Fennica 41(3): 471–487. https://doi.org/10.14214/sf.284.

Nuutinen Y., Björheden R. (2016). Productivity and work processes of small-tree bundler Fixteri FX15a in energy wood harvesting from early pine dominated thinnings. International Journal of Forest Engineering 27(1): 29–42. https://doi.org/10.1080/14942119.2015.1109175.

Nuutinen Y., Laitila J., Rytkönen E. (2014). Grinding of stumps, logging residues and small diameter wood using a CBI 5800 grinder with a truck as a base machine. Baltic Forestry 20(1): 176–188.

Nuutinen Y., Petty A., Bergström D., Rytkönen M., Di Fulvio F., Tiihonen I., Lauren A., Dahlin B. (2016). Quality and productivity in comminution of small-diameter tree bundles. International Journal of Forest Engineering 27(3): 179–187. https://doi.org/10.1080/14942119.2016.1223926.

Official Statistics of Finland (2016). Wood in energy generation 2015. Natural Resources Institute Finland (Luke). http://stat.luke.fi/en/wood-energy-generation. [Cited 20 Sept 2016].

Pettersson M., Nordfjell T. (2007). Fuel quality changes during seasonal storage of compacted logging residues and young trees. Biomass Bioenergy 31(11–12): 782–792. https://doi.org/10.1016/j.biombioe.2007.01.009.

Pochi D., Civitarese V., Fanigliulo R., Spinelli R., Pari L. (2015). Effect of poplar fuel wood storage on chipping performance. Fuel Processing Technology 134: 116–121. https://doi.org/10.1016/j.fuproc.2015.01.023.

Ranta T. (2002). Logging residues from regeneration fellings for biofuel production – a GIS-based availability and cost supply analysis. Lappeenranta University of Technology, Acta Universitatis Lappeenrantaensis 128. 180 p.

Ranta T. (2005). Logging residues from regeneration fellings for biofuel production–a GIS-based availability analysis in Finland. Biomass and Bioenergy 28(2): 171–182. https://doi.org/10.1016/j.biombioe.2004.08.010.

Rauch P. (2010). Stochastic simulation of forest fuel sourcing models under risk. Scandinavian Journal of Forest Research 25(6): 574–584. https://doi.org/10.1080/02827581.2010.512876.

Rauch P. (2013). Improving the primary forest fuel supply chain. Bulletin of the Transilvania University of Braşov. Series II. Vol. 6(55). No.1.

Rinne S., Holmberg H., Myllymaa T., Kontu K., Syri S. (2014). Wood chip drying in connection with combined heat and power or solar energy in Finland. In: Sarkadi L., Kroó N., Armaroli N., Ongena J., McEvoy A., Fülöp Z. (eds.). E2C 2013 – 3rd European Energy Conference. Hungarian Chemical Society, Roland Eötvös Physical Society. https://doi.org/10.1051/epjconf/20137903008.

Röser D., Mola-Yudego B., Sikanen L., Prinz R., Gritten D., Emer B., Väätäinen K., Erkkilä A. (2011). Natural drying treatments during seasonal storage of wood for bioenergy in different European locations. Biomass and Bioenergy 35(10): 4238–4247. https://doi.org/10.1016/j.biombioe.2011.07.011.

Routa J., Kolström M., Ruotsalainen J., Sikanen L. (2015a). Precision measurement of forest harvesting residue moisture change and dry matter losses by constant weight monitoring. International Journal of Forest Engineering 26(1): 71–83. https://doi.org/10.1080/14942119.2015.1012900.

Routa J., Kolström M., Ruotsalainen J., Sikanen L. (2015b). Validation of prediction models for estimating the moisture content of small diameter stem wood. Croatian Journal of Forest Engineering 36(2): 283–291.

Spinelli R., Glushkov S., Markov I. (2014). Managing chipper knife wear to increase chip quality and reduce chipping cost. Biomass and Bioenergy 62: 117–122. https://doi.org/10.1016/j.biombioe.2014.01.007.

Strandström M. (2016a). Puunkorjuu ja kaukokuljetus vuonna 2015. [Timber Harvesting and Long-distance Transportation of Roundwood 2015]. Metsätehon tuloskalvosarja 4a/2016. 32 p. [In Finnish].

Strandström M. (2016b). Metsähakkeen tuotantoketjut Suomessa vuonna 2015. [Production chains of forest chips in Finland in 2015]. Metsätehon tuloskalvosarja 7/2013. 20 p. [In Finnish].

Tomppo E., Katila M., Moilanen J., Mäkelä H., Peräsaari J. (1998). Kunnittaiset metsävaratiedot 1990–94 [Municipality level forest resource data, years 1990–94]. Metsätieteen aikakauskirja 4B/1998: 619–839. [In Finnish]. https://doi.org/10.14214/ma.6453.

Tomppo E., Henttonen H., Tuomainen T. (2001). Valtakunnan metsien inventoinnin menetelmä ja tulokset metsäkeskuksittain Pohjois-Suomessa 1992–94 sekä tulokset Etelä-Suomessa 1986–92 ja koko maassa 1986–94. [The method and the results of national forest inventory in forest centres in North Finland 1992–94, and results in South Finland 1986–92 and in whole country 1986–94]. Metsätieteen aikakauskirja 1B: 99–248. [In Finnish]. https://doi.org/10.14214/ma.6434.

Valtioneuvoston asetus ajoneuvojen käytöstä tiellä (407/2013). [The Finnish government regulation for road vehicles]. http://www.finlex.fi/fi/laki/alkup/2013/20130407#Pidm1799696/.

Varis O. (2014). Polttohakkeen tuotantokustannukset. [Production costs of wood chips used as a fuel]. Bachelor’s thesis. JAMK University of Applied Sciences. 62 p.

Virkkunen M., Raitila J., Korpinen, O.-J. (2016). Cost analysis of a satellite terminal for forest fuel supply in Finland. Scandinavian Journal of Forest Research 31(2): 175–182. https://doi.org/10.1080/02827581.2015.1082617.

Windisch J., Väätäinen K., Anttila P., Nivala M., Laitila J., Asikainen A., Sikanen L. (2015). Discrete-event simulation of and information-based raw material allocation process for increasing the efficiency of an energy wood supply chain. Applied Energy 149: 315–325. https://doi.org/10.1016/j.apenergy.2015.03.122.

Wolfsmayr U.J., Rauch P. (2014). The primary forest fuel supply chain: A literature review. Biomass and Bioenergy 60: 203–221. https://doi.org/10.1016/j.biombioe.2013.10.025.

Volumes and prices in energy wood trade (2016). Volumes and prices in energy wood trade 2015–2016. Natural Resources Institute Finland (Luke). http://stat.luke.fi/en/tilasto/4450/julkistukset. [Cited 20 Sept 2016].

Total of 71 references.