Timber extraction by cable yarding on flat and wet terrain: a survey of cable yarder manufacturer’s experience

Erber G., Spinelli R. (2020). Timber extraction by cable yarding on flat and wet terrain: a survey of cable yarder manufacturer’s experience. Silva Fennica vol. 54 no. 2 article id 10211. https://doi.org/10.14214/sf.10211

Highlights

- Survey of all European cable yarder manufacturers on flat-terrain yarding

- Manufacturers are frequently contacted concerning flat-terrain yarding

- Forest resource inaccessibility, regulatory and environmental considerations are most important motivations

- Lack of clearance, tree stability and installation costs are major challenges

- Mobile, self-anchoring tail spar is considered a chief adaptation

- Cost-competitiveness with ground-based systems cannot be achieved without subsidies

- Increasing environmental awareness and climate change present opportunity to expand flat-terrain cable yarding.

Abstract

Cable yarding is a general solution for load handling on sites not accessible to ground-based machinery, and is typically associated with steep terrain. On flat terrain, such conditions can primarily be found on soft or wet soils, most frequently encountered in Central and Northern European countries. Today, changed environmental and market conditions may offer an unprecedented opportunity to the actual implementation of cable yarding on flat terrain in commercial operations. The study goal was to collect cable yarder manufacturers experience regarding the use and adaption of cable yarding technology on flat terrain. European manufacturers of cable yarding technology were interviewed about customer experience, particular challenges, adaptation potential, future potential and main hurdles for the expansion of cable yarding on flat terrain. Almost all manufacturers have received requests for flat-terrain yarding technology solutions, primarily from Germany. Temporal or permanent inaccessibility, regulatory or environmental reasons were the most frequent motivation for considering cable yarding technology. Installation was considered particularly challenging (clearance, stable anchoring). Potential adaptations included higher towers, artificial anchors, mechanized bunching before extraction and un-guyed yarder-systems. An artificial, highly mobile, self-anchoring tail spar was considered the most useful adaptation. While concerned about limited profitability and qualified labour shortage, most manufacturers demonstrated a positive or neutral view concerning the expansion of cable yarding on flat terrain. However, cable yarding is not considered to be cost-competitive wherever ground-based systems can be employed and cable yarding is not subsidized.

Keywords

forest soils;

soil compaction;

logging equipment;

sensitive soils

-

Erber,

University of Natural Resources and Life Sciences Vienna, Department of Forest and Soil Sciences, Institute of Forest Engineering, Peter Jordan Strasse 82, 1190 Vienna, Austria

https://orcid.org/0000-0003-1606-5258

E-mail

gernot.erber@boku.ac.at

https://orcid.org/0000-0003-1606-5258

E-mail

gernot.erber@boku.ac.at

-

Spinelli,

CNR-IBE Consiglio Nazionale delle Ricerche-Istituto per la BioEconomia, Via Madonna del Piano 10, Sesto Fiorentino, Firenze, I-50019, Italy; AFORA, University of the Sunshine Coast, Locked Bag 4, Maroochydore, QLD, Australia

https://orcid.org/0000-0001-9545-1004

E-mail

spinelli@ivalsa.cnr.it

https://orcid.org/0000-0001-9545-1004

E-mail

spinelli@ivalsa.cnr.it

Received 18 June 2019 Accepted 20 February 2020 Published 4 March 2020

Views 128553

Available at https://doi.org/10.14214/sf.10211 | Download PDF

1 Introduction

Forest management, and especially timber harvesting, can have large impacts on soils due to the equipment used for timber extraction. Soil disturbance and compaction are the effects of heavy machine traffic during ground-based timber extraction (Cambi et al. 2015), and may hamper regeneration and cause significant yield losses (Thompson et al. 1998; Grulois 2007; Gebauer et al. 2012). Revitalisation and amelioration of compacted soils is a long-term process and it is unknown if a complete recovery can always be achieved (Gebauer et al. 2012). Therefore, methods for removing timber with less damage to both residual vegetation and the soil are required, especially on sites prone to erosion or impassable due to wet and soft soils (Thompson et al. 1998; Worrell et al. 2010). On flat terrain, such unfavourable conditions can be encountered in mire, swamp and floodplain forests, as well as the large share of boreal forest growing on peatland.

The issue of soft and wet terrain has become increasingly urgent, and for two main reasons. Environmental awareness has grown over time, decreasing the tolerance for soil disturbance (Abbas et al. 2018), and global warming has reduced the extent and the duration of soil freezing, which has been a solution to traffic on soft and wet terrain up to now (Mohtashami et al. 2017). In the past, these sites would be accessed in winter, when the soil was frozen solid and could support heavy loads with minimum damage: today, many sites are no longer as cold as required for the soil to freeze, or the cold season is much shorter than before, thus reducing the window of opportunity for effective ground-based harvesting (Goltsev and Lopatin 2013; Daniel et al. 2018). In Finland, Lehtonen et al. (2019) found that by the mid-21st century the period of frozen soil conditions will have decreased by one month, and by the end of the century many sites will lack these conditions altogether. Such problems are compounded by a third factor: the increasing size and weight of ground-based equipment, pursued in an attempt to boost productivity (Nordfjell et al. 2019).

Cable yarding is generally associated with steep terrain; however, it is rather a general solution to load handling on sites not suited to tractor traffic (Samset 1985). In the Alps, where most modern yarder developments originated (Bont and Heinimann 2012), it has become the most common steep slope harvesting technique. Today, hundreds of cable-yarding contractors are active in the Alpine area, and especially in Austria, Germany, Italy and Switzerland (Spinelli et al. 2013).

The gentler mode of operation with regard to soils is considered cable yarding’s outstanding advantage over ground-based operations on flat and wet sites (LeDoux and Baumgras 1990; Stokes and Schilling 1997; Thompson et al. 1998; Owende et al. 2002; Grulois 2007; Teschner 2016) and a frequent reason for selecting this extraction technology (Biernath 2009; Biernath 2011; Biernath 2016; Haberl 2015; Mussong and Hofmann 2016; Kirsten 2019). As no heavy machines traverse the terrain, soil impacts are minimized or eliminated altogether (Sturos and Thompson 1996). Thompson et al. (1998) compared site disturbance after cable yarding of tree lengths to shortwood extraction by forwarder and grapple skidding of tree lengths after felling with a tracked feller-buncher and motor-manual processing on flat, sensitive sites in Minnesota. Cable yarding disturbed a much smaller share (9%) of the total area than the forwarder (31%) or grapple skidder (60%) option. Similar results were reported for two case studies in Germany’s northeastern province of Mecklenburg-Vorpommern (Sündermann et al. 2013). The lower degree of disturbance is explained by the way loads are extracted in cable yarding: partially or fully suspended above the ground, they apply little pressure to the soil. Compared to skidding by tractors, this reduces the amount of disturbed soil (Brown and Kellogg 1996; Thompson et al. 1998; Owende et al. 2002). Causes for soil disturbance and compaction are limited to (mechanized) felling (and processing) operations, and to occasional dragging of the load during extraction (Thompson et al. 1998). In the latter case, soil disturbance is restricted to segments of the yarding corridor lacking clearance, which can be avoided by intermediate supports (Brown and Kellogg 1996; Richter 2015). The gentle work mode enables extraction in watershed protection areas, that are not accessible to conventional ground-based extraction for environmental reasons (Brown and Kellogg 1996).

Advantages of cable yarding include the temporal and spatial extension of the harvesting season on sensitive sites, as soils do not need to be frozen (Thompson et al. 1998; Kirsten 2019). In this respect, Silande (1999) reported that seasonal limitations in the mountains limit French crew’s work period to 6 to 7 months a year, resulting in low utilization rates and reduced annual production. Therefore, Grulois (2007) suggested to extend cable yarding operations to sensitive soils in the plains during wintertime; a step that some German contractors have taken already (Biernath 2011).

However, cable yarding on flat and wet terrain presents specific challenges. Firstly, the carriage can not be moved by gravitation. Therefore, installation of a haul-back line becomes inevitable (Thompson et al. 1998), entailing additional installation cost. This can only be avoided by employing self-propelled carriages, which require neither main nor haul-back line. Further, carriage speed is lower in flat terrain yarding (Thompson et al. 1998), which results in lower productivity. Secondly, cable yarding requires tail holds and suitable anchors and – depending on yarding distance – intermediate supports. Trees are the preferable option for these elements (Marchi et al. 2018). However, these are often not available, as trees in wet areas are prone to shallow rooting and thus easy uprooting (Thompson et al. 1998).

Approaches to tackle these challenges include pre-rigging corridors to reduce unproductive time during installation (Thompson et al. 1998), artificial and/or mobile tail holds/spars to compensate for the lack of natural ones (Fraser and Robinson 1998a; Fraser and Robinson 1998b; TU Dresden 2016) and increasing tower height and skyline tension to allow for longer single spans (TU Dresden 2016). Heavy base machines present means of stability (Owende et al. 2002), as in case of the Koller KX304 and KX800E (Koller 2019), Teleforest (Teleforest 2019) or Herzog’s Grizzly 400 (Herzog 2019) machines.

Introduction of cable yarding to flat and wet sites is not a new idea and it has been used intermittently for decades (Williams 1908; Lidgerwood 1919; Ziemer 1980; Koten and Peters 1985; Meek 1997). Yarding equipment was already placed atop railroad cars in the early 1900s to move logs to the railroad line (Williams 1908; Lidgerwood 1919). Today, changed environmental and market conditions may offer an unprecedented opportunity to a more wide-spread implementation of flat-terrain cable yarding in commercial operations. Recent articles in professional journals suggest this practice has gained some traction in Central Europe (Biernath 2009; Biernath 2011; Schröter 2011; Haberl 2015; Biernath 2016; Kirsten 2019), and might soon expand to Eastern Europe and Fenno-Scandia, where cable-yarding has always been outperformed by more productive and less costly ground-based systems.

Therefore, the goal of this study was to collect cable yarder manufacturer´s experience regarding the use and adaption of cable yarding technology on flat terrain. For their role at the top of the technology supply chain, manufacturers are most likely to know if, where and under what conditions their equipment is used (or can be used) on flat terrain. Obviously, they will also know if their equipment can receive (or has received) specific adaptations for optimum performance in flat terrain. To this end, the authors interviewed all European manufacturers of cable yarding technology, with just three exceptions. Three sub-goals were formulated: 1) to investigate manufacturer’s experience with customers working on flat terrain, 2) to explore their opinion concerning the particular challenges of cable yarding on flat terrain and where they see adaption potential and 3) to learn about their view of cable yarding’s future potential on flat terrain and the main hurdles for expanding its use under these conditions.

2 Material and methods

2.1 Sample

The survey was conducted between February and April 2019, and it was geographically limited to manufacturers of cable yarding equipment with headquarters in a European country. Manufacturers qualified if their product range included at least one tower yarder or a sled winch designed for the installation of a cableway system. Simple winches designed for dragging loads on the ground, without the use of a skyline, were not considered eligible. Manufacturers offering only carriages were excluded from the survey.

2.2 Interviews

The authors developed a simple and concise interview form, including 13 questions ordered within four thematic groups (Table 1). Five of the questions could be answered by either yes or no and were followed by an open sub-question in case of a positive answer. The intention of the sub-questions was to further elaborate on the respective topics. General comments and opinions were also encouraged and recorded for later categorization and analysis. Altogether, 18 manufacturers were contacted via e-mail or telephone and asked if they would be willing to participate in the survey. To the authors knowledge, this number is equivalent to a full inventory under the study limitations.

| Table 1. Interview form displaying thematic groups, question ID, question content and category. ID’s display thematic groups and question level (letters for the thematic group, one digit numbers for questions, double-digit numbers for sub-questions). | |||

| Thematic group | ID | Question/Sub-question | Category |

| Company figures | A1 | Company establishment year | Numeric |

| A2 | Number of employees (SME classification; European Commission, 2017 ) | Categorical (<10, 10–49, 50–249, >249) | |

| A3 | Market size (number of countries) | Numeric | |

| A4 | Number of produced yarding equipment per year | Categorical (<10, 10–19, 20–50, >50) | |

| Customer experience | B1 | Has your company ever received requests from customers concerning cable yarding equipment for use in flat and/or wet terrain conditions? | Binary (yes, no) |

| B11 | If yes, from which country/countries? | Open | |

| B2 | Does your company offer cable yarding equipment that has been specifically adapted to flat and/or wet terrain conditions? | Binary (yes, no) | |

| B21 | If yes, what have these adaptions been? | Open | |

| B3 | Are you aware of customers that are using your equipment for cable yarding operations on flat and/or wet terrain? | Binary (yes, no) | |

| B31 | If yes, do you know what their primary motivations to use this system are (in order of perceived priority)? | Open | |

| Specific challenges and adaption potential | C1 | From your point of view, what are the specific challenges of cable yarding on flat and/or wet terrain concerning installation, with particular respect to anchors, intermediate supports, tail hold trees and clearance? | Open |

| C2 | From your point of view, what are the specific challenges of cable yarding on flat and/or wet terrain concerning operation, with particular respect to productivity and cost? | Open | |

| C3 | From your point of view, what are the specific challenges of cable yarding on flat and/or wet terrain concerning other areas? | Open | |

| C4 | Do you think cable yarding equipment could be specifically adapted to better suit for flat and/or wet terrain conditions? | Binary (yes, no) | |

| C41 | If yes, what would these adaptions be? | Open | |

| Future potential | D1 | Do you think that the demand for cable yarding operations on flat terrain will increase as a result of altered operation conditions (climate change and society’s environmental awareness)? | Binary (yes, no) |

| D2 | What do you think are the main hurdles to a further expansion of cable yarding in flat terrain? | Open | |

2.3 Analysis

Interview notes were immediately entered into Microsoft Word as individual files, corresponding to each interviewed manufacturer. All interview files were then read by the same lead researchers, who looked for commonly voiced opinions and comments that could be gathered under the same conceptual category. This categorized data was entered into a single master data base for further processing. As described in the goal statement, the study’s primary aim was to collect cable yarder manufacturer´s experience regarding the use and adaption of cable yarding technology on flat terrain. For this reason and due to the type of collected data, analysis focused on descriptive statistics and no further statistical analysis was conducted.

3 Results

3.1 Company figures

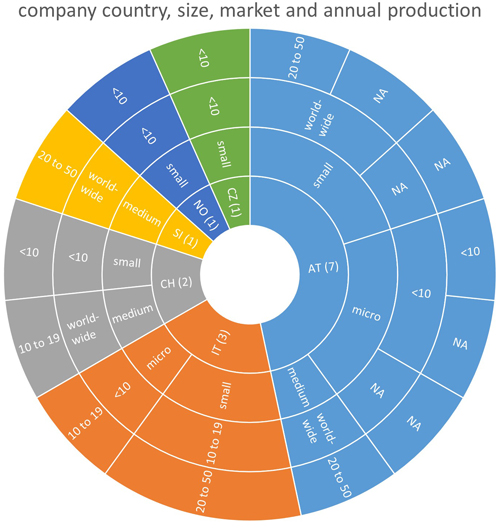

The final database contained 15 observations, because three out of the 18 eligible manufacturers declared they had no time or interest for the survey. This corresponds to a positive response rate above 80%. While originating from six different countries (Fig. 1), the companies were concentrated in the alpine region (13 in Austria, Italy, Slovenia and Switzerland). The other two were based in other mountainous regions of Europe (Czech Republic and Norway).

Fig. 1. Company country and number of companies per country in bracket (innermost circle; AT = Austria, IT = Italy, CH = Switzerland, SI = Slovenia, NO = Norway, CZ = Czech Republic), size (second circle from centre; according to SME classification of the European Commission (2017)), market size in terms of the number of countries sold to (third circle from the centre) and average annual number of produced pieces of cable yarding equipment (outermost circle). Wherever NA is stated, this type of information could either not be provided by the companies or they were not willing to share it.

The production of cable yarding equipment is mostly with micro (27%) and small (53%) enterprises (Fig. 1). Only a fifth of the manufacturers belonged to the medium enterprise category. However, the number of employees working for a manufacturer does not necessarily reflect their output of cable yarding equipment, as most manufacturers have a wider portfolio of products – and especially larger ones.

Five of the companies declared to operate “worldwide” (20 or more countries), while market size was considerably smaller for the majority of them, with two companies selling in 10 to 19 countries, and six companies selling in less than 10 countries (Fig. 1). Two companies refused to answer this question.

Five of the respondents stated that they produced 20 to 50 pieces of cable yarding equipment (tower yarders, sled winches) a year (Fig. 1). Two reported a production between 10 and 19 pieces, while further four declared that they produced less than 10 pieces a year. Four companies did not want to answer this question.

3.2 Customer experience

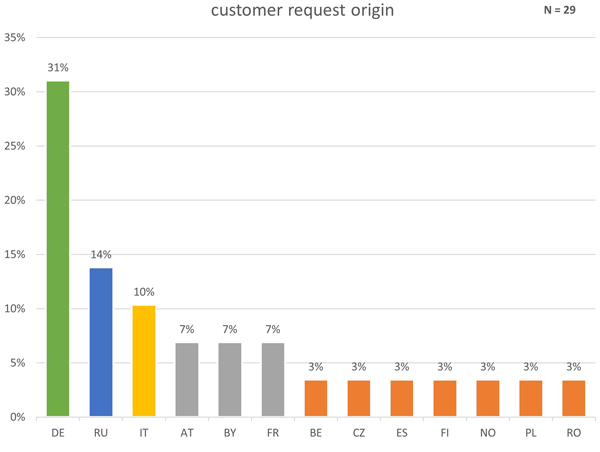

All but one company declared they had received customer requests concerning cable yarding on flat terrain in the past. Among them, one company specified that the requests concerned flat but not wet terrain, while all the others indicated that flat and wet terrain was the main subject of the requests. Only one respondent stated that they’ve never been contacted concerning such matters. The respondents declared that most requests came from Germany (named 9 times out of 29 mentioned countries) (Fig. 2). Russia was named four and Italy three times, while Austria, France and Belarus received two nominations each. One nomination each was recorded for Belgium, Finland, Norway, Poland, Romania, Spain and Switzerland.

Fig. 2. Origin of customer requests for flat terrain cable yarding technology by country (DE = Germany, RU = Russia, IT = Italy, AT = Austria, BY = Belarus, FR = France, BE = Belgium, CZ = Czech Republic, ES = Spain, FI = Finland, NO = Norway, PL = Poland, RO = Romania).

Eleven of the companies stated that they had already adapted their machinery to flat and wet terrain conditions or that they were able to adapt it based on customer demand. Four companies stated that they did not offer specific adaptations for use in flat and wet terrain.

Three major groups of adaptations were identified from a total of 13 mentioned ones. The first group included adaptations of the base machine (23%) to improve the mobility of the winch assembly on difficult terrain, such as the use of wide tracks and other improved locomotion devices (tracked base machines). A second group (54%) covered adaptations of the winch assembly, designed to make operation independent of slope and to increase line lift. These included three-drum-systems (skyline, mainline and back-haul line), closed-ring circuits (endless loop) systems for sled winches (winches mounted on a sled-like structure and generally used in long-distance cable yarding), extended towers, artificial supports, self-propelled carriages, twin-carriage systems (Studier and Binkley 1974; Samset 1985) for horizontal extraction of whole trees and longer chokers for pre-concentrated loads. Finally, a third group of answers (23%) pointed at the self-supporting, excavator-based yarder concept as a solution to overcome the limitations in anchor availability possibly encountered on flat and wet terrain.

Ten of the companies were aware of customers employing their equipment on flat and wet terrain in forestry (Fig. 2), while further two reported of non-forestry customers using their machines in flat terrain for construction work. One pointed out that they have customers in both sectors. Only two declared that they were not aware of any customer activities in flat-terrain operations.

Out of a total of 22, permanent (wet or rock strewn terrain) or temporarily (shortened frost periods) inaccessibility for ground-based machinery was the most frequently (45%) named motivation for employing cable yarding on flat and wet terrain. Regulatory reasons were the second most important group of reasons (32%). This category included restrictions to ground-based machine traffic imposed by nature conservation or watershed protection measures, as well as governmental interventions, i.e. subsidies to support low-impact harvesting, as achieved by cable yarding. The smallest group (23%) reported that the implementation of cable yarding on flat terrain was motivated by pure environmental considerations on otherwise accessible areas.

3.3 Specific challenges and adaptation potential

Flat-terrain challenges were collected and analyzed separately for installation and operation. Concerning installation, 73% of the respondents indicated that limited terrain clearance was the most important challenge when deploying cable yarding technology on flat and wet terrain. Half of these further stated that this lack of clearance results in shortened span lengths (75 m to 200 m), which necessitates time consuming and costly installation of a higher number of intermediate supports than would be required on a steep slope. Strategies for meeting this challenge included restriction to single spans and increased skyline tension. However, at least one company mentioned that increased skyline tension has drawbacks in the form of reduced payload capacity, higher strain on the anchors and an increased risk of causing the skyline to slip out of the support jacks. A further challenge mentioned by seven manufacturers was the absence of suitable trees to serve as anchors, tailhold and intermediate supports. Respondents further indicated that the lack of suitable anchors is especially challenging in broadleaved stands (smaller trees, hindrance by the crown), after forest damage (trees have been blown down) and where forests are bordered by agricultural land (permanent absence of trees) – all situations being especially frequent when operating on flat terrain. While on the subject, and on an opposite note, some respondents pointed out that the installation of artificial anchors might be easier on flat terrain, where there is more space and machine accessibility is better than generally found in steep terrain. That would be the case of taking an excavator on site, in order to bury deadman anchors or to act as an anchor itself. Concern about challenges encountered during operation was less frequent (53%) than for those related to installation, and it was difficult to identify a clear pattern or focus. Three respondents indicated that productivity during operation on flat and wet terrain may be close to (or slightly above) that achieved for downhill yarding, but certainly below the higher productivity obtained for uphill yarding. Experience of the yarding crew, efficient pre-concentration and a sufficient harvesting volume per corridor were considered important success factors. If mentioned at all, high operating costs were linked to the more complicated installation or the purchase price of dedicated flat-terrain cable yarding equipment.

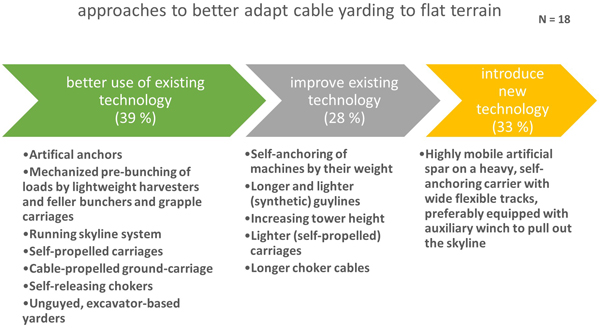

All but two companies stated that they saw potential for the specific adaptation of cable yarding equipment to flat and wet terrain conditions. Proposed solutions were classified into three groups: better use of already existing technology, actual mechanical adaptations of existing technology and new, purpose-built devices (Fig. 3).

Fig. 3. Major groups of approaches to better adapt cable yarding to flat terrain and examples of mentioned adaptations.

Out of a total of 18, seven (39%) were classified as new ways of using already existing technological solutions. The use of artificial anchors, such as deadman or machine anchors was advocated by several respondents as a solution to overcome anchoring issues. Manufacturers offering self-supporting, excavator-based yarder technology stated that this system is superior to other cable yarder types because of lower capital costs, faster and easier installation and lower workforce requirements. A further approach to overcome tree instability on wet terrain was to employ a wheeled platform (“ground-carriage”) similar to a forwarders bunk, which operates similarly to a self-propelled carriage along a “skyline” that is suspended between the harvester, which directly cuts or lifts the logs onto the bunk, and a truck situated on the forest road, equipped with a crane for unloading (Konrad 2020). One respondent considered tail spar stability to be less of an issue if running skyline systems were employed, as they would exert less strain on the tail spar. Pre-bunching of loads before extraction is expected to improve yarding productivity in general. To achieve this effect, respondents favoured mechanized felling and pre-bunching and one specified that this should be done by light tracked harvesters or feller-bunchers.

One respondent pointed out that the advantage of bunched loads should be exploited further by employing grapple carriages. Employing self-propelled carriages on flat terrain was considered to offer increased efficiency at low capital cost. After all, this type of carriage had been designed for such conditions from the very start. Furthermore, a more widespread adoption of self-releasing chokers was advocated by one respondent, while another demonstrated a very hands-on attitude by suggesting waterproof footwear for the yarding crew.

Increasing the height of the tower was the most frequently named adaptation among adaptations to existing technology, which comprised 28% of the mentioned solutions. One respondent argued that longer guylines would allow a more favourable anchoring angle, thus exerting less upward pulling force on the trees (or stumps) used as anchors, while another advocated general adoption of synthetic guylines to reduce worker strain during installation. In order to improve the mobility of lattice mast type intermediate supports and tail spars, placing them on sled-like platforms was suggested. Self-anchoring of cable yarders by their own weight was seen as a way to overcome the anchoring challenge. By reducing the weight of carriages, their payload could be increased, particularly that of self-propelled carriages, which remain quite cumbersome structures up to now. Finally, longer choker cables were suggested to be able to make better use of pre-bunched trees.

The third group comprised of variations of one main innovation, which was a mobile artificial tail spar. The idea behind it was to overcome challenges related to lack of clearance and stability at once. Firstly, the tail hold should be of a height that would allow long spans, possibly eliminating the need for intermediate supports and thus reducing set up time. The respondents referred to the desired height as “canopy height”, but did not specify what this might mean in terms of meters. However, they made it clear that height would be above today’s tower heights and that this approach would require improvements in anchoring. Placing the spar on a heavy base machine and thus anchoring it by merely the machine’s own weight was considered the preferable solution. A tracked base machine would be preferred over a wheeled one. Its operation mode would be to move parallel to the cable yarder from corridor to corridor on connecting paths. To further facilitate installation, the machine should be equipped with an auxiliary winch to pull out the skyline. One respondent considered an excavator with wide flexible tracks (swamp tracks) as the optimal solution, because this vehicle would be able to free itself if stuck on wet terrain.

3.4 Future potential and main hurdles

Most survey respondents demonstrated either a positive (47%) or neutral (33%) attitude towards the possibility that the demand for cable yarding on flat and wet terrain may increase in the near future. Only a fifth of the respondents were sure that cable yarding on flat terrain will remain a (stable) niche business. Increased environmental awareness of both the public and forest industry was seen as a driver to expansion, as forest managers and harvesting contractors are expected to prevent extensive soil disturbance. Further, some public and private forest owners have already imposed restrictions on extraction technology, often in the form of prohibiting the employment of ground-based systems. Finally, decreased accessibility of forest resources as a result of reduced soil bearing capacity due to a lack of frozen soil conditions or the need to access forest resources in difficult terrain to fulfill raw material demand was identified as a major driver for an expansion of cable yarding in flat terrain. Neutral respondents were either simply inconclusive or had a differentiated view with regard to differences in attitude between countries or the availability of subsidies.

About two thirds of the named obstacles to a further expansion of cable yarding on flat and wet terrain referred to limited profitability. High operating costs due to complicated installation and especially in comparison to ground-based alternatives were the respondents´ major concern: they stated that successful expansion may only be possible through legal restrictions on ground-based harvesting systems, or through subsidies in support of yarding that may offset the higher operating costs. Two manufacturers stated that dedicated cable yarding equipment might be too expensive to permit widespread adoption, especially among farmers. A single respondent was concerned about the inefficiency and high cost due to a lack of bunching, given that machine access constraints would favour motor-manual felling over mechanized felling and the former cannot achieve a good pre-bunching of felled trees. If pre-bunching is possible, he said one should employ a grapple carriage to take advantage of the bunched loads. A further respondent mentioned that cable yarding will be at a disadvantage compared to harvester and forwarder, as long as it cannot be operated safely at night.

Workforce-related hurdles comprise the second group of obstacles. All respondents in this group complained about the severe shortage of qualified and motivated personnel experienced by the forest sector in general, and by cable yarding contractors in particular. Working on wet terrain was considered the least attractive: even if moving might be less tiresome on flat terrain than on a steep slope, walking through wet and muddy terrain was considered particularly unattractive. One participant indicated the construction industry as a most serious competitor, capable of offering easier jobs for a qualified workforce. Several respondents reported that labour shortage forced customers to cancel anticipated machine purchases. In the opinion of one respondent, this issue can only be overcome by technological innovation that would allow operating without workers in the field.

4 Discussion and conclusions

4.1 Limitations of the study

First of all, this study represents the views and opinions of the interviewed company representatives and might be biased by their subjective experience, area of operation and own portfolio of products. On the other hand, most questions were relatively neutral, and the data was checked for plausibility and consistency, which excluded gross distortions. Of course, the geographic scope of the survey makes it representative of European yarding technology only: different yarding concepts developed in other areas may present different opportunities and limitations when it comes to operation in flat terrain and if so, these additional elements are not included in this study that represents the specific experience of European manufacturers. That is especially relevant when one considers that most early studies on flat-terrain cable yarding come from North America (LeDoux and Baumgras 1990; Stokes and Schilling 1997; Thompson et al. 1998). In some ways, the difference in space and time between those earlier studies and the current survey offers an opportunity to gauge the evolution of both the issues and the proposed solutions. The discussion that follows seems to deny any major progress in this debate, as far as the general principles are concerned.

Second, some degree of subjectivity was unavoidable when the researchers categorized the open questions: other researchers may have attributed some answers to different categories than it was done here by the authors of this paper. Nevertheless, answers were grouped into categories with the utmost care and after extensive discussion, whenever attribution was doubtful. Furthermore, the final decision was always taken by the same researcher, in order to guarantee the internal consistency of the dataset.

Third and final, the dataset was unbalanced concerning manufacturer characteristics, as expressed by number of employees, market share and annual production of cable yarding equipment. As the sample size is equivalent to a full inventory, the answers and their distribution can be considered representative for the European manufacturers of cable yarding equipment.

4.2 Technology

Broadly speaking, the survey indicates that: a) almost all manufacturers have received requests for flat-terrain yarding technology solutions and b) that almost all have adequate solutions available within their own product range. However, the majority of these solutions are generic all-terrain yarding products, rather than individual items specifically designed for flat-terrain yarding. There are exceptions to this general statement, e.g. self-propelled artificial intermediate supports developed by at least two manufacturers or high-flotation tracked base machines for improving off-road mobility and machine stability (Sündermann et al. 2013). This indicates that existing technology is generally flexible enough to allow cable yarding over a wide range of different site conditions, including flat and wet terrain, thereby confirming Samset’s (1985) conclusion that it is a true all-terrain load-handling solution.

4.3 Market

Again, almost all manufacturers know of customers who have used or are regularly using their yarders on flat terrain, although the reasons for doing so – when they are known – are not exclusively related to poor bearing capacity and/or soil protection requirements, but occasionally include excessive roughness (i.e. rocks) and/or the need to avoid trail blazing. Yarding on flat terrain seems to occur in many countries, but Germany is by far the most represented. This matches the extensive coverage found in the German language professional journals (Biernath 2009; Biernath 2011; Schröter 2011; Haberl 2015; Biernath 2016; Kirsten 2019), research reports (Richter 2015; Adler 2016; Mussong and Hoffmann 2016; TU Dresden 2016; Teschner 2016) and thematic events, such as the KWF thematic days (Deutscher Landwirtschaftsverlag 2013; Sündermann et al. 2013). The German prevalence may be explained by an ideal combination of geography, economy and culture. On one hand, soft and wet terrain is well represented in Germany, especially in the Northern part. That is not the case in the other European countries located further south, where there is not much flat terrain available to forestry and/or where a drier climate reduces the presence of wetlands. These are the countries where cable yarding is generally associated with steep terrain. Conversely, the German territory offers steep Alpine conditions in the South and more Nordic wetland conditions in the North, and that favours the movement of ideas and enterprises. At the same time, a relative wealth and a generally favourable wood market (despite the ups and downs of all markets today) may leave some additional margins for environmental compliance – that is, reinvesting some of the profits into environmental protection. Finally, Germany has a strong tradition for environmental awareness, which has generated a very strong emphasis on reducing the impact of forest operations. At any rate, all respondents indicate that the implementation of cable yarding technology in flat terrain is a niche business in all countries, Germany included. What is more, the majority of respondents believe that flat- terrain yarding will stay a niche business in the near future, even if the changing climate and societal demands may cause some limited expansion.

4.4 Challenges and opportunities

There is a general agreement for what concerns the main challenges: a higher harvesting cost than incurred when using ground-based equipment (financial challenge), a clearance problem due to the unfavourable terrain profile (technical challenge) and a growing shortage of qualified labor (workforce challenge).

Cost for ground-based extraction with forwarders in Europe vary between studies and with country, machine type, extraction distance and treatment (thinning, regeneration felling). Figures normally vary from 4 to 10 € m–3 (Enache et al. 2016; Moskalik et al. 2017; Proto et al. 2018). Extraction by cable yarding is considerably more expensive, and can exceed 20 € m–3 (Enache et al. 2016). When accounting for the complete harvesting cost – i.e. felling, processing and extraction – figures range from 8 to 16 € m–3 for ground-based harvesting in Nordic Europe (LUKE 2019), and over 40 € m–3 for cable-based harvesting in the Alps (Spinelli et al. 2015). In France, a direct comparison between the cost of ground-based and cable-based harvesting indicates that the average contract rate is 12 € m–3 for ground-based operations and 48 € m–3 for cable-based operations (Spinelli et al. 2017). Considering the large disparity in unit cost between forwarder and cable yarder extraction, it is highly unlikely that cable yarding will ever be competitive on flat terrain, even if all adaptations suggested by the manufacturers were applied. However, this statement may only be valid for areas where ground-based systems can be employed at acceptable degrees of soil disturbance.

On the contrary, the clearance hurdle is straightforward, and refers to the disadvantages suffered when cable yarding is deployed in flat terrain, as opposed to steep terrain. In that regard, respondents agree on the challenge and on the solutions, generally identified with increasing the height of the tower and the number of supports.

Finally, the shortage of qualified labor is a general challenge experienced by the forest sector worldwide (Koirala et al. 2017; Payn 2018). The three main reasons for labour shortage in forestry listed in a recent study from New Zealand (MPI 2019) are probably valid in a European context too. They are: (1) inability to attract new entrants in the business, (2) unattractive employment conditions (pay rates, work hours and location etc.) and (3) experienced staff leaving the industry. Competition with other industries ranked number four out of seven. The State of Europe’s Forest 2015 report (FOREST EUROPE 2015) indicates that around 30% of all people employed in forestry in Europe are at least 49 years old, and attracting young people to study and work in the forest sector is considered a main challenge. This shortage may hit cable yarding especially hard because of the larger labour requirements of cable technology compared to other work methods, since additional operators must station on the cutover, exposed to the elements, for hooking the loads (Stampfer et al. 2010).

Respondents offered many different and insightful suggestions to make flat-terrain yarding more efficient and competitive. Those classified as new ways of employing existing technology may simply reflect a lack of imagination in deploying technology already used in other areas (e.g. radio controlled chokers). Others, such as reducing tail spar stress by employing a running skyline system might be new under European conditions only. Actually, this system has already been successfully tested by Lisland (1996) in Norway. Increased mechanization might present a way to more efficiently pre-bunch loads and thus boost yarder productivity and offset installation-related delays (Brown and Kellogg 1996; Lisland 1996; Visser and Stampfer 1998; Spinelli et al. 2019), especially in combination with a grapple carriage. Interestingly, one respondent specifically asked for light tracked harvesters or feller-buncher to pre-bunch loads. Considering the trade-off between crane reach and machine size, the use of low-mass machinery would implicate a shorter crane reach and necessitate a tighter spacing of corridors. Ultimately more corridors would be required and less volume would be harvested per corridor. More corridors would mean higher installation costs for the cable yarder and probably a larger area would be impacted by traffic. Therefore, the respondent’s motivation for this statement more likely stemmed from soil bearing capacity considerations and from the assumption that lighter machines correspond to lower soil impact, not considering the various implications. However, this problem could be overcome by the cutting-strip method, where small-size harvesters with a crane reach of 5 to 7 m travel on a cutting strip inside the stand on so-called “ghost trails” and pile the processed logs at the strip roads to the left and right (Ovaskainen et al. 2006). On the other hand, corridor spacing could be increased beyond double the common harvester’s reach of 10 m by felling trees by chainsaw towards the corridor in order to make them accessible to the harvester for processing.

Taking more machines on site could speed up building of artificial anchors – or the machines could be employed as anchors, making installation less dependent on tree anchors and allowing the exact calculation of anchor resistance (Leshchinsky et al. 2015). Lately, self-anchoring of machines has successfully been realized, usually for excavator-based machines (Herzog 2019; Koller 2019). Increasing tower height would improve cable yarding efficiency on flat terrain by eliminating or reducing the need for intermediate supports. However, respondents indicated that this has been done before on customer request. Canopy height is often referred to as the desired tower height. Depending on tree species, site conditions and stand age, this would range between 10 m and 35 m. The latter figure would correspond to double the height of the largest European tower at the moment (17 m; Wassermann 2019). The most futuristic concept was a highly mobile, self-anchoring, canopy-height tail spar. It is envisioned to speed up installation by eliminating the need for intermediate supports and setting up a tree tail spar. Combined with a self-anchoring cable yarder, this would eliminate any anchoring requirements. However, this machine would have to be large and heavy, as demonstrated by a solution from Canada (Teleforest 2019), where two 20 ton excavators with 18 m masts support the skyline. Summing up, the majority of the proposed innovations aimed to simplify and speed up installation by reducing demand for natural anchors, intermediate supports and tail spars. Innovations to improve operational efficiency focused on mechanized pre-bunching and improved loading and unloading practises. Finally, the Authors believe that the general versatility of flat-terrain yarding solutions would make it possible to integrate flat-terrain and steep-terrain contracts within a company’s work schedule in order to increase machine utilization. Most mountain operations are paused during winter due to heavy snow conditions, and that justifies the interest for stop-gap jobs (Silande 1999). Coming down to the lowlands for some flat-terrain yarding could then represent a useful job integration that avoids seasonal shut down (Grulois 2007).

4.5 Future scenarios

None of the respondents expects a rapid general expansion of flat-terrain cable yarding in the short term, but all seem relatively positive that this practice will gain ground over time. However, several external indicators may justify more optimism. Environmental awareness is already high in many countries, and it keeps growing almost everywhere. Furthermore, the duration of the frozen ground period is getting shorter every year in most regions of the globe (e.g. in Finland; Lehtonen et al. 2019), which makes it increasingly urgent to find new harvesting solutions. Manufacturers of ground-based solutions seek to lower the impact of machine traffic on soils by enlarging the contact area between machine and soil through adapting tyre pressure, hydro-pneumatic suspension (e.g. the Forwarder2020 project, FORWARDER2020) and employing wider or longer tracks (Ala-Ilomäki et al. 2011), as well as by reinforcing strip roads with brush mats (LaBelle et al. 2019) or smart routing solutions to bypass areas of very low bearing capacity. Recent developments for soft terrain include an optional fifth axle for PONSSE forwarders or a forwarder with a rubber-tracked undercarriage (OnTrack project, OnTrack 2017). The high level of activity indicates that ground-based solutions will continue to be the most efficient means to extract timber on flat terrain, as improved machine mobility is likely to balance the decline in terrain traversability. For cable yarding, some of the suggested adaptations mentioned have the potential to improve competitiveness on flat terrain in the near future: Acuna et al. (2011) found that bunching of trees increased yarding productivity by 25% and Raymond (2017) showed that radio-controlled grapple carriages equipped with video cameras could render stationing and exposing humans on slope unnecessary, while increasing productivity by 35%. However, even if all adaptions were implemented, cable yarding on flat terrain is likely to be restricted to areas where ground-based systems are undesirable for excessive soil disturbance or legal prohibition and where the desire for cable yarding is expressed by subsidies.

Acknowledgements

The research leading to these results was conducted as part of the TECH4EFFECT project. This project has received funding from the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 720757.

References

Abbas D., Di Fulvio F., Spinelli R. (2018). European and United States perspectives on forest operations in environmentally sensitive areas. Scandinavian Journal of Forest Research 33(2): 188–201. https://doi.org/10.1080/02827581.2017.1338355.

Acuna M., Skinnell J., Evanson T., Mitchell R. (2011). Bunching with a self-levelling feller-buncher on steep terrain for efficient yarder extraction. Croatian Journal of Forest Engineering 32(2): 521–531. http://www.crojfe.com/site/assets/files/3787/07acuna_521-531.pdf. [Cited 05 Feb 2019].

Adler K. (2016). Verbundvorhaben: Entwicklung und Prototypenbau eines Seilkransystems für den Holztransport auf nicht befahrbaren, ebenen und nassen Standorten. [Joint project: Development and prototype construction of a cable yarding system for timber extraction on non-trafficable, flat and wet sites]. Konrad Adler GmbH & Co. KG, Wolfegg, Germany. 44 p. http://www.gbv.de/dms/tib-ub-hannover/892780940.pdf. [Cited 18 Jun 2019].

Ala-Ilomäki J., Högnas T., Lamminen S., Siren M. (2011). Equipping a conventional wheeled forwarder for peatland operations. International Journal of Forest Engineering 22(1): 7–13. https://doi.org/10.1080/14942119.2011.10702599.

Biernath D. (2009). Das ist sanfte Forstwirtschaft. [This is gentle forestry]. Forstmaschinen-Profi 17(9): 13–15.

Biernath D. (2011). Give me Moor! [Give me moor!]. Forstmaschinen-Profi 19(5): 12–14.

Biernath D. (2016). Seilkran in der Ebene? - Eben darum! [Cable yarding on flat terrain? That’s why!]. Forstmaschinen-Profi 24(11): 18–22.

Bont L., Heinimann H. (2012). Optimum geometric layout of a single cable road. European Journal of Forest Research 131: 1439–1448. https://doi.org/10.1007/s10342-012-0612-y.

Brown C.G., Kellogg L.D. (1996). Harvesting economics and wood fiber utilization in a fuels reduction: a case study in eastern Oregon. Forest Products Journal 46: 45–52.

Cambi M., Certini G., Neri F., Marchi E. (2015). The impact of heavy traffic on forest soils: a review. Forest Ecology and Management 338: 124–138. https://doi.org/10.1016/j.foreco.2014.11.022.

Daniel J.S., Jacobs J.M., Miller H., Stoner A., Crowley J., Khalkhali M., Thomas A. (2018). Climate change: potential impacts on frost–thaw conditions and seasonal load restriction timing for low-volume roadways. Road Materials and Pavement Design 19(5): 1126–1146. https://doi.org/10.1080/14680629.2017.1302355.

Deutscher Landwirtschaftsverlag (2013). KWF-Thementage vom 1./2. Oktober 2013: Umweltgerechte Bewirtschaftung nasser Waldstandorte. [Environmentally compatible management of wet forest sites]. Der Wald- Allgemeine Forst Zeitschrift für Waldwirtschaft und Umweltvorsorge (AFZ) 18. 60 p. https://www.kwf-online.de/images/KWF/Wissen/Veroeffentlichungen/FTI/Archiv/2013/FTI_9-10_2013-es_final.pdf. [Cited 18 Jun 2019].

Enache A., Kühmaier M., Visser R., Stampfer K. (2016). Forestry operations in the European mountains: a study of current practices and efficiency gaps. Scandinavian Journal of Forest Research 31(4): 412–427. https://doi.org/10.1080/02827581.2015.1130849.

European Commission (2017). User guide to the SME Definition. Publications Office of the European Union, Luxembourg. 60 p. https://doi.org/10.2873/620234.

FOREST EUROPE (2015). State of Europe’s Forests 2015. Ministerial Conference on the Protection of Forests in Europe, Madrid, Spain. 314 p. https://www.foresteurope.org/docs/fullsoef2015.pdf. [Cited 12 Feb 2020].

FORWARDER2020 – Forwarder 2020 project (2020). https://www.forwarder2020-project.eu/. [Cited 06 Feb 2020].

Fraser D., Robinson D. (1998a). Excavator mobile anchoring methods. LIRO Report 23(4): 6 p.

Fraser D., Robinson D. (1998b). Tractor mobile anchoring methods. LIRO Report 23(5): 7 p.

Gebauer R., Jindřich N., Ulrich R., Martinková M. (2012). Soil compaction – impact of harvesters’ and forwarders’ passages on plant growth. In: Garcia J.M., Diez Casero J.J. (eds.). Sustainable forest management – current research. Intech. p. 179–196. https://doi.org/10.5772/30962.

Goltsev V., Lopatin E. (2013). The impact of climate change on the technical accessibility of forests in the Tikhvin District of the Leningrad Region of Russia. International Journal of Forest Engineering 24: 148–160. https://doi.org/10.1080/19132220.2013.792150.

Grulois S. (2007). Cable-yarding in France: past, present and perspective. DEFOR Project Report - Task 1.1 - INTERREG IIIB SUDOE. 5 p. http://www.iefc.net/wp-content/uploads/2018/05/DEFORreport1.4.1.pdf. [Cited 18 Jun 2019].

Haberl A. (2015). Soweit die Seile reichen. [As far the cables reach]. Österreichische Forstzeitung 5, Arbeit im Wald (AIW): 14.

Herzog (2019). https://www.herzog-forsttechnik.ch/wp-content/uploads/2019/08/Prospekt-Grizzly-400-Yarder_2012.pdf. [Cited 05 Sep 2019].

Kirsten H. (2019). Seilkraneinsätze auf ebenen, empfindlichen Standorten. [Cable yarding operations on flat, sensitive sites]. Kuratorium für Waldarbeit und Forsttechnik (KWF) e. V: Forsttechnische Informationen 2: 5–9.

Koirala A., Kizha A.R., Roth B. (2017). Perceiving major problems in forest products transportation by trucks and trailers: a cross-sectional survey. European Journal of Forest Engineering 3: 23–34.

Koller (2019). https://www.kollergmbh.com/de/kippmastgeraete/kx304. [Cited 05 Sep 2019].

Konrad (2020). https://www.forsttechnik.at/en/products/ground-carriage-pully.html. [Cited 06 Feb 2020].

Koten D.E., Peters P.A. (1985). Cable yarding on environmentally sensitive areas in New York State. In: Proceedings of the 8th COFE Meeting, August 18–22 1985, Tahoe City, CA. p. 79–83.

LaBelle E.R., Poltorak B.J., Jaeger D. (2019). The role of brush mats in mitigating machine-induced soil disturbances: an assessment using absolute and relative soil bulk density and penetration resistance. Canadian Journal of Forest Research 49(2): 164–178. https://doi.org/10.1139/cjfr-2018-0324.

LeDoux B.C., Baumgras J.E. (1990). Cost of wetland protection using cable logging systems. Proceedings of the 13th COFE Meeting – August 12 to 16 1990, Outer Banks, NC. p. 38–43.

Lehtonen I., Venäläinen A., Kämäräinen M., Asikainen A., Laitila J., Anttila P., Peltola H. (2019). Projected decrease in wintertime bearing capacity on different forest and soil types in Finland under a warming climate. Hydrology and Earth System Sciences 23: 1611–1631. https://doi.org/10.5194/hess-23-1611-2019.

Leshchinsky B., Sessions J., Wimer J. (2015). Analytical design for mobile anchor systems. International Journal of Forest Engineering 26(1): 10–23. https://doi.org/10.1080/14942119.2015.1023014.

Lidgerwood (1919). Commercial advertising of the Lidgerwood Skidder. Southern Lumberman, September 13: 77. https://babel.hathitrust.org/cgi/pt?id=uiug.30112054681470&view=1up&seq=521. [Cited 23 Aug 2019].

Lisland T. (1996). Use of cable systems on soft ground in Norway. Proceedings of the FAO/ECE/ILO seminar on environmentally sound forest roads and wood transport, June 17–22 1996, Sinaia, Romania. http://www.fao.org/3/X0622E/x0622e13.htm. [Cited 18 Jun 2019].

LUKE (2019). Statistics database: unit costs in mechanised harvesting of roundwood by felling method. http://statdb.luke.fi/PXWeb/pxweb/en/LUKE/LUKE__04%20Metsa__08%20Muut__Teollisuuspuun%20korjuu%20ja%20kaukokuljetus/05.12_Koneellisen_puunkorjuun_yksikkokustannuks.px/?rxid=001bc7da-70f4-47c4-a6c2-c9100d8b50db. Finnish Natural Resources Institute (LUKE). [Cited 4 Feb 2020].

Marchi E., Grigolato S., Mologni O., Scotta R., Cavalli R., Montecchio L. (2018). State of the art on the use of trees as supports and anchors in forest operations. Forests 9(8): 1–17 p. https://doi.org/10.3390/f9080467.

Meek P. (1997). Preliminary trials of wood extraction by cable yarding on soft soils. Forest Engineering Research Institute of Canada, Field Note No.: Cable Yarding-16. 2 p.

Mohtashami S., Eliasson L., Jansson G., Sonesson J. (2017). Influence of soil type, cartographic depth-to-water, road reinforcement and traffic intensity on rut formation in logging operations: a survey study in Sweden. Silva Fennica 51(5) article 2018. 14 p. https://doi.org/10.14214/sf.2018.

Moskalik T., Borz S.A., Dvořák J., Ferenčík M., Glushkov S., Muiste P. Lazdiņš A. Styranivsky O. (2017). Timber harvesting methods in Eastern European countries: a review. Croatian Journal of Forest Engineering 38: 231–241. http://www.crojfe.com/site/assets/files/4083/moskalik.pdf. [Cited 31 Oct 2019].

MPI (2019). 2019 Forestry labour requirements survey. https://www.mpi.govt.nz/dmsdocument/33484/direct. Ministry for Primary Industries, Wellington, New Zealand. 19 p. [Cited 4 Feb 2020].

Mussong M., Hofmann J. (2016). Technikanpassung zur umwelt- und naturverträglichen Bewirtschaftung wiedervernässter Standorte im Wald. [Technological adaption for environmentally compatible management of wet forest sites]. Green Owl Development, Berlin, Germany. 22 p.

Nordfjell T., Öhman E., Lindroos O., Ager B. (2019). The technical development of forwarders in Sweden between 1962 and 2012 and of sales between 1975 and 2017. International Journal of Forest Engineering 30(1): 1–13. https://doi.org/10.1080/14942119.2019.1591074.

OnTrack – OnTrack Project (2017). https://www.linkedin.com/pulse/ontrack-ontrack-project/. [Cited 06 Feb 2020].

Ovaskainen H., Uusitalo J., Sassi T. (2006). Effect of edge trees on harvester positioning in thinning. Forest Science 52: 659–669.

Owende P.M.O., Lyons J., Haarlaa R., Peltola A., Spinelli R., Ward S.M. (2002). Operations protocol for eco-efficient wood harvesting on sensitive sites. ECOWOOD Partnership. 74 p.

Payn T. (2018). Future environmental challenges and New Zealand’s planted forests. New Zealand Journal of Forestry 63: 14–20.

Proto A., Macrì G., Visser R., Harrill H., Russo D., Zimbalatti G. (2018). Factors affecting forwarding productivity. European Journal of Forest Research 137: 143–151. https://doi.org/10.1007/s10342-017-1088-6.

Raymond K. (2017). Steepland harvesting programme – final programme report. Ministry for Primary Industries and Forest Growers Research Ltd, New Zealand. 37 p.

Richter L. (2015). Untersuchung zu Boden- und Bestandesschäden der Seilkrananlage „FlatLift”. [Investigation of soil and stand damage of the cable yarder „Flat Lift“]. BSc diploma thesis, Technical University Dresden, Tharandt, Germany. 40 p.

Samset I. (1985). Winch and cable systems. Martinus Nijhoff/Dr. W. Junk Publishers, Dordrecht, The Netherlands. 539 p.

Schröter P. (2011). Mit der Seilbahn übers Moor. [Over the moor by cable yarder]. Forstmaschinen-Profi 19(11): 22–23.

Silande G. (1999). Le débardage par câble en France. Situation actuelle et perspectives. [Cable yarding in France. Current situation and perspectives]. Mémoire de fin d’étude. ENGREF. 80 p.

Spinelli R., Magagnotti N., Facchinetti D. (2013). A survey of logging enterprises in the Italian Alps: firm size and type, annual production, total workforce and machine fleet. International Journal of Forest Engineering 24(2): 109–120. https://doi.org/10.1080/14942119.2013.838376.

Spinelli R., Visser R., Thees O., Sauter H.U., Krajnc N., Riond C., Magagnotti N. (2015). Cable logging contract rates in the Alps: the effect of regional variability and technical constraints. Croatian Journal of Forest Engineering 36(2): 195–203. http://www.crojfe.com/site/assets/files/4012/spinelli.pdf. [Cited 12 Feb 2020].

Spinelli R., Visser R., Riond C., Magagnotti N. (2017). A survey of logging contract rates in the southern European Alps. Small Scale Forestry 16: 179–193. https://doi.org/10.1007/s11842-016-9350-1.

Spinelli R., Lombardini C., Marchi E., Aminti G. (2019). A low-investment technology for the simplified processing of energy wood from coppice forests. European Journal of Forest Research 138: 31–41. https://doi.org/10.1007/s10342-018-1150-z.

Stampfer K., Leitner T., Visser R. (2010). Efficiency and ergonomic benefits of using radio controlled chokers in cable yarding. Croatian Journal of Forest Engineering 31(1): 1–9. http://www.crojfe.com/site/assets/files/3843/01-stampfer_1-9.pdf. [Cited 18 Jun 2019].

Stokes B.J., Schilling A. (1997). Improved harvesting systems for wet sites. Forest Ecology and Management 90(2–3): 155–160. https://doi.org/10.1016/S0378-1127(96)03907-2.

Studier D., Binkley V. (1974). Cable logging systems. Reprinted in 1979 by O.S.U. Book Stores Inc. Corvallis, Oregon, USA. 190 p.

Sturos J.A., Thompson M.A. (1996). Cable yarding as low-impact alternative on sensitive sites in the lake states. In: Proceedings of the 19th COFE Meeting, July 29 – August 1 1996, Marquette, MI. p.109–116.

Sündermann J., Schröder J., Röhe P. (2013). Bodenschonende Holzernte in geschädigten Eschenbeständen auf Nassstandorten: Erkenntnisse und Empfehlungen aus Fallstudien in Mecklenburg-Vorpommern. [Soil protective harvesting of damages ash stands on wet sites: Lessons learned and recommendations from case studies in Mecklenburg-Western Pomerania]. Ministerium für Landwirtschaft, Umwelt und Verbraucherschutz Mecklenburg-Vorpommern (LU), Schwerin, Germany. 44 p. https://www.regierung-mv.de/serviceassistent/download?id=104185. [Cited 18 Jun 2019].

Teleforest (2019). https://www.teleforest.com/. [Cited 05 Sep 2019].

Teschner J. (2016). Die ökonomische und ökologische Beurteilung eines Kurzstreckenseilkraneinsatzes im horizontalen Rückeverfahren auf Nassstandorten in der Rostocker Heide. [Economical and ecological evaluation of short distance horizontal cable yarding on wet sites on the Rostock heath]. BSc diploma thesis, Hochschule für Nachhaltige Entwicklung Eberswalde, Germany. 124 p.

Thompson M.A., Mattson J.A., Sturos J.A., Dahlman R., Blinn C.R. (1998). Case studies of cable yarding on sensitive sites in Minnesota. Improving forest productivity for timber, a key to sustainability. Conference proceedings. p. 118–124. https://www.forestry.umn.edu/sites/forestry.umn.edu/files/cfans_asset_356674.pdf. [Cited 12 Feb 2020].

TU Dresden (2016). Verbundvorhaben: Entwicklung und Prototypenbau eines Seilkransystems für den Holztransport auf nicht befahrbaren, ebenen und nassen Standorten [Joint project: Development and prototype construction of a cable yarding system for timber extraction on non-trafficable, flat and wet sites]. Bundesministerium für Ernährung und Landwirtschaft, Berlin, Germany. 90 p. https://doi.org/10.2314/GBV:890448337.

Visser R., Stampfer K. (1998). Cable extraction of harvester felled thinnings: An Austrian case study. Journal of Forest Engineering 9: 39–46.

Wassermann C., Kühmaier M., Stampfer K. (2019). Marktübersicht - Europäische Mastseilgeräte. [Market overview - European tower yarders]. Österreichische Forstzeitung 7: 1–8.

Williams A.S. (1908). Logging by steam. Journal of Forestry 6: 1–33.

Worrell W.C., Bolding C.M., Aust M.W. (2010). Comparison of potential erosion following conventional and cable yarding timber harvests in the Appalachian plateau region of Virginia. Proceedings of the 33th COFE Meeting – June 6 to 9 2010, Auburn, AL. 8 p.

Ziemer I. (1980). Preliminary study to establish the feasibility of cable yarding in the Lake States. Final report for Cooperative Agreement 13-564 (FS-NC-3701-77-03). 42 p. USDA Forest Service, 410 MacInnes Drive, Houghton, MI.

Total of 70 references.