Comparing the efficiency of drum and disc chippers

Spinelli R., Cavallo E., Eliasson L., Facello A. (2013). Comparing the efficiency of drum and disc chippers. Silva Fennica vol. 47 no. 2 article id 930. https://doi.org/10.14214/sf.930

Abstract

The study compared the effect of chipper type on productivity, power demand, fuel consumption and product quality. Tests were conducted on two commercial chipper models, a disc and a drum chipper. Both chippers had the same diameter capacity, were applied to the same tractor and fed with the same feedstock types. Fifteen replications were conducted per machine and for each of four different feedstock types, reaching a total of 120 tests. The disc chipper had a higher energy efficiency and used 19% less fuel per unit product, possibly due to its simpler design, integrating comminuting and discharge system in one synergic device. In contrast, the drum chipper was 8% more productive, since it cut with the same energy all along the length of its knives. The drum chipper produced smaller chips, with a higher incidence of fines. Feedstock type had a strong effect on productivity, energy efficiency and product quality. The effect of feedstock type was mainly related to piece size, and may be stronger than the effect of chipper type. Further studies should determine the effect of blade wear on the relative performance of the two chipper types.

Keywords

productivity;

biomass;

wood;

energy;

fuel

-

Spinelli,

CNR IVALSA, Via Madonna del Piano 10, Sesto Fiorentino (FI), Italy

E-mail

spinelli@ivalsa.cnr.it

- Cavallo, CNR IVALSA, Via Madonna del Piano 10, Sesto Fiorentino (FI), Italy E-mail e.cavallo@imamoter.cnr.it

- Eliasson, Skogforsk, Uppsala Science Park, SE-751 83 Uppsala, Sweden E-mail lars.eliasson@skogforsk.se

- Facello, CNR IVALSA, Via Madonna del Piano 10, Sesto Fiorentino (FI), Italy E-mail a.facello@ima.to.cnr.it

Received 28 November 2012 Accepted 11 April 2013 Published 18 June 2013

Views 101434

Available at https://doi.org/10.14214/sf.930 | Download PDF

1 Introduction

Comminution is an essential element of all modern energy wood chains, because automated boilers need homogeneous fuel particles within specified size limits (Strehler 2000). Besides, comminution offers additional benefits in terms of increased load density and improved handling quality (Röser et al. 2012). For this reason, low-density raw materials should be chipped as early as possible, in order to accrue such important benefits all along the supply chain (Björheden 2008).

Sound knowledge of technology alternatives is a main step to optimal deployment, which is made the more urgent by the ambitious European Union targets for the year 2020 (Stupak et al. 2007). These targets require mobilizing the large unutilized wood resource already available in the territories of member states (Ericsson and Nilsson 2006). In turn, massive mobilization can only be achieved if the cost of harvesting, processing and transportation is dramatically reduced (Moiseyev et al. 2011). All steps in the supply chain must be optimized, including chipping, which accounts for a large share of the overall supply cost (Papworth and Erickson 1966). Such an effort requires determining if one chipper design is inherently more efficient than the other, in terms of productivity and energy use or if it produces a higher product quality.

Based on comminution principle, commercial chippers come in three main types: disc chippers, drum chippers and cone-screw chippers (Pottie and Guimier 1985). The first two types are by far the most used, whereas cone-screw-chippers are seldom used professionally when producing energy chips and are the object of further development (Wegener and Wegener 2012).

Mobile disc chippers are especially common in North America for production of pulp chips, whereas drum chippers find a secondary use for brush disposal, often in gardening operations (Goldstein and Diaz 2005). In Europe, disc chippers or large drum chippers are used on terminals for chipping of logs, while the drum chippers dominate the chipping of logging residues and small trees on landings (Kärhä 2011).

Both chipper types have been in use for many years and much anecdotal evidence is available about their relative merits. Operators state that disc chippers produce more uniform chips than drum chippers, especially if fed with good quality raw material. In contrast, flexible small branches may pass through the disc slots uncomminuted, resulting in low chip quality. For this reason, operators believe that drum chippers are the best when dealing with small-size feedstock, such as tops and branches (Spinelli and Hartsough 2001). Few scientific comparisons of the two chipper types have been made, rarely with comparable settings for the machines (cf. Young and Hatton 1976; Heikka and Piirainen 1981; Liss 1984; Liss 1987).

The goal of this study is to compare the specific effect of chipper type (disc or drum) on productivity, power demand, fuel consumption and product quality, using different raw material types and running both machine types under comparable (controlled) conditions.

2 Materials and methods

Two mobile chippers were made available by Pezzolato SpA (www.pezzolato.it) and were used for the experiment: a Pezzolato PTH 300 G drum chipper (Fig. 1) and a Pezzolato H880/250 disc chipper (Fig. 2). The chippers had the same log diameter capacity and were set to produce the same cut length, with a blade offset equal to 15 mm and 13 mm for the drum and the disc chipper respectively. Both chippers used a two-blade configuration. The drum chipper was equipped with a 50 mm square mesh sieve and the disc chipper with a three-blade piece breaker, in order to limit the production of oversize particles to the same 50 mm maximum length (Table 1). Both chippers were new from the factory, eliminating machine wear as a factor in the study. Both chippers were alternately connected to the same 100 kW farm tractor, a new Case New Holland 140. The rotation regime of the tractor power take off (PTO) was set to the specifications recommended by the chipper manufacturer for each chipper model: 750 rpm for the drum chipper and 540 rpm for the disc chipper.

| Table 1. Characteristics of the test chippers. | ||

| Type | Drum | Disc |

| Make | Pezzolato | Pezzolato |

| Model | PTH 300 G | H880/250 |

| Year | 2012 | 2012 |

| Serial # | CI 5240 | CI 5389 |

| Weight kg | 2320 | 1460 |

| Knives n° | 2 | 2 |

| Blade offset mm | 15 | 13 |

| Screen mm | 50 | NA |

| Piece breaker | NA | 3 blades, 40 mm |

Fig. 1. The experimental set up with the PTH 300 G drum chipper.

Fig. 2. The experimental set up with the H 880/250 disc chipper.

The tests were conducted in March 2012 at the wood yard of the Mombracco chip-fired power station in Envie, Northwestern Italy. Both machines were alternately fed with four different feedstock types: poplar sawmill residues, poplar branches, poplar logs and chestnut logs. All feedstocks were fresh and came in pieces with an approximate length of 2 m. The average moisture content of chestnut logs was 44%, and that of the poplar assortments was between 50 and 52%. The feedstocks were chosen because they are widely available and often used for chip production in the area.

The study included 15 repetitions per combination of chipper type and feedstock, totalling 120 repetitions (2 chippers x 4 feedstock types x 15 repetitions). Feedstocks were manually fed to each chipper in a random sequence in order to dampen the influence on results from progressive blade wear (Nati et al. 2010). Tests were started with new blades on both machines. Each repetition consisted of around 100 kg of material. The amount of material used was kept intentionally small, in order to contain the effect of blade wear and to guarantee that the machine was under continuous load for the whole duration of the replicate. It is difficult to feed large amounts of material to the chipper in a uniform way, and uneven feeding is likely to generate “jagged” load graphs, with peaks and lows, which are more difficult to analyze.

Torque was measured with a strain-gauge based torque meter giving a rated voltage output of 2 mV∙V–1 @ 2250 Nm. Torque measurement accuracy was 0.7 Nm. Rotational speed was determined with a 60 tooth gear coupled with a magnetic speed sensor giving a pulse output directly proportional to the speed, accurate to 1 Hz∙rpm–1 @ 5000 rpm). This information was used for calculating power output.

Fuel consumption was measured with a volumetric fuel meter directly connected to the engine feed lines (send and return line). The fuel meter had two PT100 thermocouples connected respectively to the send and return lines for determining the fluid temperature and calculating the appropriate fuel density. Fuel meter accuracy was 0.04 L h–1.

All sensors were connected to a pc-based multichannel acquisition system that filtered, processed, displayed and recorded all incoming signals. The instrument could acquire up to 8 analogue channels and up to 24 digital channels, with a maximum sample rate of 10 ks∙s–1. For this study the recording sampling rate was fixed to 45 samples per second, using 3 analogue (torque meter bridge and thermocouples) and 2 digital channels (speed sensor and fuel meter).The acquisition software was configured for real-time processing of acquired data. Therefore, one could immediately observe such parameters as instantaneous power (kW) and fuel (L∙h–1) use.

Effective time consumption was determined on the power and fuel consumption graphs, rather than by timing the actual work (Spinelli et al. 2011b). When a machine is processing small batches, it is difficult for an external observer to accurately determine when the machine is working and when it is running idle. In fact, the machine evacuation system will keep spitting small amounts of chips for many seconds after the drum has finished its job. During this time the engine work load is dropping again. Under real work conditions, a new load would be engaging the drum at this stage, and the engine work load would not be decreasing so sharply. To determine the beginning and the end of process time, all graphs were analyzed in order to estimate a basal power and fuel consumption figure, taken as a reference for the running machine before its drum actually engaged the wood. These reference figures were adopted as the thresholds for defining actual chipping time. All test time when fuel consumption or power output was above these levels was counted as chipping time and used for calculating net chipping productivity. Average fuel consumption when chipping was also calculated on the records above the idling threshold.

Output was determined by weighing all wood chips produced within each repetition. To this end, a metal bin was held with a forklift under the chipper spout, in order to collect the chips. The bin was connected to the forklift with a strap and a hook. The hook contained a 10 kN load cell, with a rated accuracy of 200 g. The load cell downloaded all weight data into the main pc-based multichannel acquisition system.

A single one-kg sample was collected from each repetition for determining moisture content and particle size distribution. The former was obtained with the gravimetric method, according to European standard CEN/TS 14774-2; the latter with the oscillating screen method, according to European Standard CEN/TS 15149-1. Eight sieves were used to separate the nine following chip length classes: >300 mm, 300–200 mm, 200–125 mm, 125–100 mm, 100–63 mm, 63–45 mm, 45–16 mm, 16–3 mm, <3 mm. Each fraction was then weighed with a precision scale.

Data were analyzed with the SAS statistics software using analysis of variance (Anova). Analysis of variance for particle size distribution was conducted after arcsine transformation, in order to satisfy the normality assumption.

3 Results

Productivity was 8.3 % higher for the drum chipper than for the disc chipper (Table 2) but the difference was not significant at the 5% level (p = 0.0535, Table 3). Productivity was strongly and significantly affected by feedstock type, with logs proving faster to chip than branches or saw mill residues.

| Table 2. Average time consumption (minutes) per oven-dry tonne chips by chipper and feedstock type. | |||

| Feedstock type | Disc | Drum | ∆ Disc (%) |

| Chestnut stem | 6.28a | 5.46a | 15.0 |

| Poplar branches | 10.17b | 8.99b | 13.1 |

| Poplar logs | 6.73a | 6.24a | 7.9 |

| Poplar mill residue | 9.46b | 9.46b | 0.0 |

| Note: different letters on the average values in the same column indicate statistical significance at the 5 % level; ∆ Disc (%) is the percent increment recorded for the disc chipper, assuming the drum chipper value as the reference base, i.e. ; ∆ Disc (%) = 100 * (Disc – Drum)/Drum. | |||

| Table 3. Anova table for time consumption per oven-dry tonne by chipper and feedstock type. | |||

| Source | DF | Type III SS | p |

| Chipper | 1 | 118441.383 | 0.0535 |

| Feedstock | 3 | 3447703.362 | <0.0001 |

| Chipper*Feedstock | 3 | 56431.216 | 0.6132 |

When the machines were idling, the average power consumption was 4.6 kW for the disc and 4.9 kW for the drum chipper. Under these conditions, fuel consumption was 6.3 and 8.4 L per hour for the disc and the drum chipper combination, respectively.

When working, the drum chipper needed more power than the disc chipper, and more power was needed when chipping logs compared to branches or saw mill residues (Table 4). Power requirement was dependent on the amount of material chipped per time unit, i.e. the production in oven-dry tonne per minute (Table 5). The inclusion of productivity as a covariate in the model increased the r2 from 67 to 84 per cent, compared to the anova without covariate.

| Table 4. Average power consumption (kW) when chipping by chipper and feedstock type. | |||

| Feedstock type | Disc | Drum | ∆ Disc (%) |

| Chestnut stem | 35.39a | 46.26a | –23.5 |

| Poplar branches | 21.66b | 28.83b | –24.9 |

| Poplar logs | 37.89a | 45.99a | –17.6 |

| Poplar mill residue | 27.92c | 34.51c | –19.1 |

| Note: different letters on the average values in the same column indicate statistical significance at the 5 % level; ∆ Disc (%) is the percent increment recorded for the disc chipper, assuming the drum chipper value as the reference base, i.e. ; ∆ Disc (%) = 100 * (Disc – Drum)/Drum. | |||

| Table 5. Ancova table for average power consumption when chipping by chipper and feedstock type with productivity as covariate. | |||

| Source | DF | Type III SS | p |

| Chipper | 1 | 1239.876 | <0.0001 |

| Feedstock | 3 | 1117.873 | <0.0001 |

| Chipper*Feedstock | 3 | 49.275 | 0.2561 |

| Productivity | 1 | 2423.577 | <0.0001 |

The higher average power demand of the drum chipper made it less energy efficient than the disc chipper. As an average, the drum chipper used 18% more energy per oven-dry tonne, compared to the disc chipper (Table 6). This difference was statistically significant, as were the differences caused by feedstock type (Table 7). The lower energy efficiency of the drum chipper was also reflected in the 19% higher fuel consumption per oven-dry tonne (Tables 8 and 9). Chestnut logs proved to be the most energy efficient feedstock to chip, and mill residues the least efficient, regardless of how energy consumption was measured: MJ per oven-dry tonne, or L of diesel per oven-dry tonne. The effect of feedstock type was stronger than the effect of chipper type in determining energy use (Tables 7 and 9).

| Table 6. Consumed energy (MJ) per oven-dry tonne chips by chipper and feedstock type. | |||

| Feedstock type | Disc | Drum | ∆ Disc (%) |

| Chestnut stem | 20.80a | 24.81a | –16.2 |

| Poplar branches | 21.38a | 25.34a | –15.6 |

| Poplar logs | 24.95b | 28.40b | –12.1 |

| Poplar mill residue | 26.12b | 32.15b | –18.8 |

| Note: different letters on the average values in the same column indicate statistical significance at the 5 % level; ∆ Disc (%) is the percent increment recorded for the disc chipper, assuming the drum chipper value as the reference base, i.e. ; ∆ Disc (%) = 100 * (Disc – Drum)/Drum. | |||

| Table 7. Anova table for consumed energy per oven-dry tonne by chipper and feedstock type. | |||

| Source | DF | Type III SS | p |

| Chipper | 1 | 575710069.9 | <0.0001 |

| Feedstock | 3 | 800329555.6 | <0.0001 |

| Chipper*Feedstock | 3 | 29352520.4 | 0.5779 |

| Table 8. Consumed diesel fuel (L) per oven-dry tonne chips by chipper and feedstock type. | |||

| Feedstock type | Disc | Drum | ∆ Disc (%) |

| Chestnut stem | 2.36a | 2.73a | –13.6 |

| Poplar branches | 2.92b | 3.35b | –12.8 |

| Poplar logs | 2.67b | 3.21b | –16.8 |

| Poplar mill residue | 3.11c | 3.94c | –21.1 |

| Note: different letters on the average values in the same column indicate statistical significance at the 5 % level; ∆ Disc (%) is the percent increment recorded for the disc chipper, assuming the drum chipper value as the reference base, i.e. ; ∆ Disc (%) = 100 * (Disc – Drum)/Drum. | |||

| Table 9. Anova table for consumed diesel fuel per oven-dry tonne by chipper and feedstock type. | |||

| Source | DF | Type III SS | p |

| Chipper | 1 | 8.957 | <0.0001 |

| Feedstock | 3 | 15.375 | <0.0001 |

| Chipper*Feedstock | 3 | 0.924 | 0.3818 |

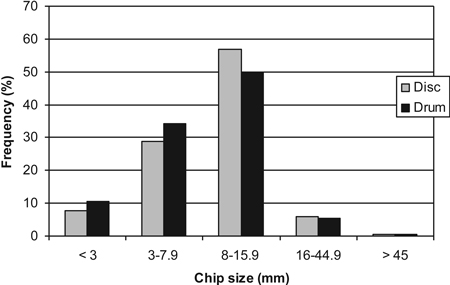

On average, the disc chipper produced significantly more acceptable size chips (8–16 mm) and significantly less small chips (8–3 mm) and fines (<3 mm) than the drum chipper (Fig. 3). There were also clear differences between feedstock types. Chestnut logs and poplar branches produced a lower amount of 8–16 mm chips and more fines (<3) than poplar logs or sawmill residues (Table 10). However, for the two finest particle size fractions there was a significant interaction between the chipper and feedstock type (Table 11). The disc chipper produced the least amount of these fractions when chipping sawmill residues, while the drum chipper obtained the same effect with poplar logs. Logically, this led to a proportional difference in the amount of 8–16 mm chips, but such difference was not large enough to cause a significant interaction effect. However, when fed with sawmill residues, the disc chipper produced a far better product than what the general comparison between the two chipper types suggests.

Fig. 3. Average chip size distribution for the disc chipper (grey bars) and drum chipper (black bars).

| Table 10. Particle size distribution by chipper and feedstock type. | ||

| Chipper | Disc | Drum |

| Chestnut logs | ||

| >45 mm | 0.1 | 0.1 |

| 45–16 mm | 3.8 | 3.4 |

| 15.9–8 mm | 50.9 | 43.7 |

| 7.9–3 mm | 36.4 | 42.6 |

| <3 mm | 8.8 | 10.2 |

| Poplar logs | ||

| >45 mm | 0.0 | 0.1 |

| 45–16 mm | 3.8 | 3.5 |

| 15.9–8 mm | 63.7 | 60.5 |

| 7.9–3 mm | 25.7 | 27.0 |

| <3 mm | 6.8 | 8.9 |

| Poplar branches | ||

| >45 mm | 0.3 | 0.4 |

| 45–16 mm | 5.5 | 5.5 |

| 15.9–8 mm | 52.7 | 44.9 |

| 7.9–3 mm | 32.0 | 36.5 |

| <3 mm | 9.5 | 12.7 |

| Sawmill residues | ||

| >45 mm | 0.5 | 0.4 |

| 45–16 mm | 9.6 | 7.8 |

| 15.9–8 mm | 62.9 | 50.5 |

| 7.9–3 mm | 21.5 | 31.1 |

| <3 mm | 5.6 | 10.2 |

| Note: data obtained from back-transformation of Arcsine transformed data. | ||

| Table 11. Anova table for particle size distribution. | |||

| Source | DF | Type III SS | p |

| >45 mm | |||

| Chipper | 1 | 6.502 * 10–5 | 0.8889 |

| Feedstock | 3 | 0.043 | 0.0063 |

| Chipper*Feedstock | 3 | 0.001 | 0.9505 |

| 45–16 mm | |||

| Chipper | 1 | 0.005 | 0.1926 |

| Feedstock | 3 | 0.237 | <0.0001 |

| Chipper*Feedstock | 3 | 0.004 | 0.6782 |

| 15.9–8 mm | |||

| Chipper | 1 | 0.179 | <0.0001 |

| Feedstock | 3 | 0.455 | <0.0001 |

| Chipper*Feedstock | 3 | 0.031 | 0.1114 |

| 7.9–3 mm | |||

| Chipper | 1 | 859.638 | <0.0001 |

| Feedstock | 3 | 3730.834 | <0.0001 |

| Chipper*Feedstock | 3 | 263.547 | 0.0529 |

| <3 mm | |||

| Chipper | 1 | 0.074 | <0.0001 |

| Feedstock | 3 | 0.065 | <0.0001 |

| Chipper*Feedstock | 3 | 0.016 | 0.0458 |

| Note: analysis conducted after arcsine transformation. | |||

4 Discussion

The amount of wood processed during the experiment was relatively small (7.1 oven-dry tonnes), and much smaller than used for more conventional studies, where a trailer load is often taken as the observation unit (Spinelli and Magagnotti 2013). However, this study was conducted on single batches with the specific goals of: 1) containing the effect of blade wear and 2) making sure that the machine was under continuous load for the whole duration of the test. Furthermore, the individual size of each replicate was representative of the single load that is fed manually or with a small grapple to machines that are designed for being fed that way. All measures were taken to guarantee that the small replicate size would not bias the reliability of our results. In particular, calculating process time from power and fuel use graphs allowed preventing the risk of manual timing errors

Analysis of data did not detect any significant drift within the same machine treatment, showing that the use of small batches succeeded in containing the effect of blade wear.

The effect of feedstock type on productivity is well known, and has been reported in previous studies (Liss 1987; Spinelli et al. 2011). The largest part of the difference can be ascribed to the effect of piece size on chipper productivity (Spinelli and Magagnotti 2010). That would explain why the highest productivity in the study was achieved for logs, and the lowest for branches and slabs.

The higher productivity recorded for the drum chipper was not significant at the 5% level, although the margin of uncertainty was very little. So, we cannot ignore the possibility that the drum chipper could be more productive than the disc chipper. That would be in accordance with earlier studies (Liss 1984; Heikka and Piirainen 1981) and may be an effect of the larger effective work width. While both test machines had the same infeed opening and were rated for the same diameter capacity, the working face of the drum chipper ran at a constant peripheral speed. On the contrary, the peripheral speed of the disc chipper varied with the distance from the disc centre, and therefore the disc chipper was less effective due to lower speed and momentum in the portion of the blade that was nearer to the centre. That is an inherent quality of disc chippers, and a conceptual difference to drum chippers.

The differences in power requirement when idling for the two chipper types are likely explained by a higher resistance of the evacuation system installed on Central European drum chippers, which in this case consists of two auger conveyors and a blower. That is made necessary by the interposition of a resizing screen between the drum and the chip outlet, which inevitably chokes the free flow of chips. Therefore, chips must be collected and moved to a separate blower for launching through the discharge spout. Disc chippers have no such screens, and the initial acceleration impressed to the chips by the integral fan blades on the outlet facing side of the disc is enough for thrusting the chips through the discharge spout, without any need for additional conveyors or blowers. The main advantage of the disc chipper design is that the two devices – comminuter and blower – are integrated into one single mechanism developing a synergic action.

In a similar study of a tractor powered Bruks 722 disc chipper Liss (1987) reported a power consumption when idling of 3.2 to 3.5 kW, which is quite close to the 4.6 kW indicated in this study. Liss also reported a mean power requirement of 18.2 kW when chipping spruce logs of 100 mm diameter with a 50 % moisture content at a temperature of –10 °C. Power requirement rose to 36.2 kW when log diameter increased to 150 mm.

Logically, logs require more power to chip compared to branches or slabs as the pieces are larger. However, the higher productivity achieved through the large piece size resulted in a better energy efficiency. This was highest with chestnut logs and lowest with poplar slabs, possibly due to the combined effect of piece size and wood characteristics, with special reference to moisture content. In fact, efficiency was calculated on the basis of dry matter, which likely favoured the drier chestnut logs. Specific fuel consumption seemed closely related to productivity, being higher for slabs and branches compared to logs.

The study did not verify that disc chippers produce more oversize particles compared to drum chippers, which is reported by many practitioners. However, the experiment was conducted on large hardwood branches with no foliage, after winter harvesting. Different results may have been obtained if chipping very small branches, with foliage and twigs. Furthermore, the test was conducted with new blades and with a rather small disc chipper, which may also explain partly unexpected results. The production of oversize particles increases with blade wear (Nati et al. 2010), and in that case the presence of a resizing screen could represent a crucial advantage offered by drum chippers. The small infeed opening makes it less likely that material will bend and reach the disc in parallel to the chipping knife. On a large disc chipper this may occur especially when fresh small diameter undelimbed material (i.e. tops or tree sections from thinnings) is chipped. Operators report that the piece breakers installed on disc chippers are not as effective as a proper resizing screen. Therefore, it could be useful to repeat the experiment with worn blades and thinner branch material. The significantly higher proportion of small chips and fines produced by the drum chipper is likely caused by the resizing screen and the more complex evacuation system, whose augers and blower “churn” and “beat” the chips.

Finally, readers should be aware that the study was conducted on two specific small-size chipper models. Although generally representative of machines in their class, the two chippers used for this study could not reflect all design options available for small size disc and drum chippers. Therefore, one should be very careful when generalizing the results of this study, especially when generalization is applied to large-size industrial chippers.

5 Conclusions

Due to their simpler design, disc chippers are more energy efficient than drum chippers, but the latter are possibly more productive. Both chipper types offer good product quality, at least as long as their blades are sharp. Drum chippers tend to produce smaller chips, with a higher incidence of fines. Further studies should determine the effect of blade wear on the relative performance of the two chipper types. Feedstock type has a strong effect on productivity, energy efficiency and product quality. The effect of feedstock type is mainly related to piece size, and may be stronger than the effect of chipper type.

Acknowledgements

This study was funded in part by the Regione Piemonte, through the project DCU NET. The Authors gratefully acknowledge the technical support of Pezzolato SpA, who offered the chipper and their personnel for the test.

References

Björheden R. (2008). Optimal point of comminution in the biomass supply chain. Proceedings of the Nordic-Baltic Conference on Forest Operations, Copenhagen 23–25 September 2008. Danish Forest and Landscape, Copenhagen, Denmark.

Ericsson K., Nilsson L. (2006). Assessment of the potential biomass supply in Europe using a resource-focused approach. Biomass and Bioenergy 30: 1–15.

Goldstein N., Diaz L. (2005). Size reduction equipment review. BioCycle 46: 41–48.

Heikka T., Piirainen K. (1981). Power consumption of small chippers. Folia Forestalia 496.

Kärhä K. (2011). Industrial supply chains and production machinery of forest chips in Finland. Biomass and Bioenergy 35: 3404–3413.

Liss J.E. (1984). Methods used by self-employed forest owners for harvesting fuel chips. Department of Operational Efficiency, Swedish University of Agricultural Sciences, Report 162.

Liss J.E. (1987). Power requirement and energy consumption in fuel-chip production using a tractor-mounted chipper. Department of Operational Efficiency, Swedish University of Agricultural Sciences. Licentiate thesis.

Moiseyev A., Solberg S., Kallio A., Lindner M. (2011). An economic analysis of the potential contribution of forest biomass to the EU RES target and its implications for the EU forest industries. Journal of Forest Economics 17: 197–213.

Nati C., Spinelli R., Fabbri P.G. (2010). Wood chips size distribution in relation to blade wear and screen use. Biomass and Bioenergy 34: 583–587.

Papworth R., Erickson J. (1966). Power requirements for producing wood chips. Forest Products Journal 16: 31–36.

Pottie M., Guimier D. (1985). Preparation of forest biomass for optimal conversion. FERIC Special Report SR-32. Pointe Claire, Canada. 112 p.

Röser D., Mola-Yudego B., Prinz R., Emer B., Sikanen L. (2012). Chipping operations and efficiency in different operational environments. Silva Fennica 46: 275–286.

Spinelli R., Hartsough B. (2001). A survey of Italian chipping operations. Biomass and Bioenergy 21: 433–444.

Spinelli R., Magagnotti N. (2010). A tool for productivity and cost forecasting of decentralised wood chipping. Forest Policy and Economics 12: 194–198.

Spinelli R., Magagnotti N. (2013). The effect of raw material, cut length, and chip discharge on the performance of an industrial chipper. Forest Products Journal. [Accepted for publication].

Spinelli R., Magagnotti N., Paletto G., Preti C. (2011). Determining the impact of some wood characteristics on the performance of a mobile chipper. Silva Fennica 45: 85–95.

Strelher A. (2000). Technologies of wood combustion. Ecological Engineering 16: 25–40.

Stupak A., Asikainen A., Jonsel M., Karltun E., Lunnan A. et al. (2007). Sustainable utilisation of forest biomass for energy – possibilities and problems: Policy, legislation, certification, and recommendations and guidelines in the Nordic, Baltic, and other European countries. Biomass and Bioenergy 31: 666–684.

Wegener J., Wegener T. (2012). The principles of helical chipping – observations based on the construction and use of different prototypes. Applied Engineering in Agriculture. [Accepted for publication].

Young H.E., Hatton J.V. (1976). Chipping of tops and branches: a comparison of a drum- and a disk-chipper. Research in Life Sciences 23: 1–11.

Total of 20 references