Ergonomic aspects and productivity of different pruning tools for a first pruning lift of Eucalyptus grandis Hill ex Maiden

Nutto L., Malinovski R. A., Brunsmeier M., Schumacher Sant’Anna F. (2013). Ergonomic aspects and productivity of different pruning tools for a first pruning lift of Eucalyptus grandis Hill ex Maiden. Silva Fennica vol. 47 no. 4 article id 1026. https://doi.org/10.14214/sf.1026

Highlights

- Pruning of hardwoods coming from forest plantations is becoming more and more important in Brazil to replace scarce wood from tropical forests

- Evaluating productivity of different pruning tools is essential for the economic output of plantations managed for high quality wood

- Pruning activities of forest workers can be classified as “hard” or “very hard work”. Depending on the tools used physical long-term damages may be prevented.

Abstract

For the substitution of wood from tropical rainforests pruning of Eucalyptus for producing valuable hardwoods in short rotation plantations has become important. Existing tools and ergonomic aspects of pruning were not yet well analysed under these conditions. The objective of the study is to evaluate the productivity and ergonomics of three different pruning tools in a pruning lift up to 3 m in height. The trees used in the study came from an 18-month-old clonal Eucalyptus grandis stand planted in a 5.0 x 2.8 m spacing. Two manual pruning tools and an electric shear were tested for productivity by using time studies. Ergonomic aspects were evaluated by two test persons using pulse meter equipment. The highest productivity could be shown for the electric shear (236 trees per working day), followed by the manual shear (196 trees/day) and the handsaw (180 trees/day). The heartbeat rate of the two test persons ranged from a level of “very hard work” for the manual tools to “middle hard” and “hard work” for the electric shear. The workload level to achieve the productivity currently reached in practice using purely manual tools is extremely high, exceeding the permanent working capacity of the operators and leading to physical degradation on the long run.

Keywords

forest management;

wood quality;

work science;

handsaw;

shear

-

Nutto,

Department for Forestry, Federal University of Paraná, Av. Pref. Lothário Meissner, 632, Curitiba, PR, Brazil

E-mail

lnutto.ufpr@gmail.com

- Malinovski, Department for Forestry, Laboratory of Forest Operations, Federal University of Paraná, Av. Prefeito Lothario Meissner, 900, Curitiba, PR, Brazil E-mail ricardo@colheitademadeira.com.br

- Brunsmeier, Chair of Forest Utilization, University of Freiburg, Werthmannstraße 6, 79085 Freiburg, Germany E-mail martin.brunsmeier@fobawi.uni-freiburg.de

- Schumacher Sant’Anna, Department for Forestry, Laboratory of Forest Operations, Federal University of Paraná, Av. Prefeito Lothario Meissner, 900, Curitiba, PR, Brazil E-mail felipe@colheitademadeira.com.br

Received 4 March 2013 Accepted 14 October 2013 Published 28 October 2013

Views 97829

Available at https://doi.org/10.14214/sf.1026 | Download PDF

1 Introduction

In the last decade the volumes of hardwood coming from the tropical rainforests in Brazil were reduced by half (SFB and IMAZON 2010). Due to better control and higher standards in sustainable forest management it becomes more and more difficult for the wood industry based on high-quality hardwood timber to meet its demand. Therefore, a clear trend can be seen, that sustainably managed high-grade tropical hardwood plantations, which provide positive economic, social and environmental benefits, play a more important role all over the world. Besides, well known plantation grown hardwood species such as teak, gmelina and eucalyptus also show high potential to provide wood of outstanding quality in relatively short rotation cycles.

In Southern Brazil considerable areas of eucalypts have been planted and managed for sawlog production in recent years. Initial spacing is kept to fewer than 750 trees per ha, and the first thinning is conducted before the trees reach 2 years of age. An early first pruning lift up to 3 m is conducted between 16 and 20 months in order to guarantee high-quality wood. Since there is no long term experience of this management method, future wood quality remains uncertain.

Little is known about branch development for such spacing, and bigger problems with missing labour force and ill employees are faced when conducting pruning activities in the planted areas. Planted eucalypts are grown under conditions where economic constraints force short rotation lengths and relatively low stocking rates in planted forests. The distinct lower initial stocking rates in planted forests delay canopy closure and the rise of the green crown. The short rotation length and unfavourable self-pruning conditions in plantations work against the production of clear wood (Montagu et al. 2003). Inefficient ejection and occlusion of branches can lead to the formation of defects within the growing stem. In all studies, knots have been the major grade-limiting factor, whether recovery was evaluated using structural or appearance criteria of eucalypts coming from forest plantations (Washusen et al. 2000). Studies from Australia, South Africa and Southern Europe strongly recommend pruning for eucalypt sawlog production (Pinkard and Beadle 1998; Henskens et al. 2001; Schönau 2002; Nutto et al. 2003). Especially when managed under a fast growing regime, as it is intended in Brazil, eucalypts tend to include dead branches partly encroaching into the stem (Medhurst et al. 2001). The targeted specifications for logs should be based on a maximum allowable knotty core diameter (Reid 1999; Stackpole 2001; Gerrand et al. 1997). To optimise time and height of pruning, more information about the branchiness of fast growing eucalypts is needed (Alcorn et al. 2007).

Information about branch diameters and length is not enough to develop efficient pruning schemes. Especially in the case of the present study, time and ergonomic efficiency of pruning tools are also necessary to improve the labour conditions and to reduce the workload of the forest workers. Careful selection of the pruning tools is essential to guarantee the success of labour-intensive pruning operations. The most common professional tools used in forestry practice are saws and shears. Studies indicate that shears show a sharper cut of the branches, cause fewer injuries to the branch collar and therefore show improved cicatrization. Wardlaw and Neilsen (1999) could prove that eucalypts pruned with shears occlude the branch stubs faster, reducing the occurrence of defects and decay. Even so, the most widely used pruning tools are handsaws because of easy handling and low training necessity as well as the lower cost and easy availability of the equipment (Stackpole 2001). For using shears the correct position of the forest operator for cutting the branch is essential, otherwise the stubs left after the cutting process become too long and increase the dimension of the knotty core. The same happens if the shear is not used in a proper way and the cutting blade is not put correctly on stem surface by the operator. This is because only one side of the shear allows to cut the branch precisely at the stem. Because of these facts the use of shears in general requires more training and handling skills than the use of a saw.

Ergonomic aspects of pruning activities are rarely considered in publications and pruning recommendations. According to information from the forest companies performing pruning activities in Brazil, it is very difficult to hire forest workers for this specific task. Using international terms of ergonomics for workload description, it may be classified as “hard” or even “very hard” work for the forest workers, very often reaching levels of physical workload exceeding the limits of the human body (Löffler 1992). This is not only due to the physical work load but is also due to the effect of temperature and humidity on humans in subtropical and tropical climates (Rodgers 1983). Under such conditions, a human being is not able to do the work over longer periods without physical degradation and serious health implications (Bernmark 2011; Caliskan and Caglar 2010).

The overall objective of the study is to compare the productivity and basic ergonomic aspects of three pruning tools in a first pruning lift of a clonal Eucalyptus grandis plantation.

Detailed objectives are:

- Analysis of the productivity (trees per working day) that can be reached using three different pruning tools.

- Analysis of the heartbeat rate of forest workers using the three different pruning tools.

2 Material and methods

The study area is located in the central part of Rio Grande do Sul, Brazil, 29°S latitude and 54°E longitude, with a predominantly sub-tropical climate. The plantation was established with Eucalyptus grandis in the year 2011, with an initial spacing of 5.0 m x 2.8 m. At the time of data collection in an 18-month-old stand, there had been no intervention so far. In the regular management regime of the company about two third of the trees are pruned up to a height of 3 m at an age between 12 and 18 month. In the present study a total of 270 trees/ha were pruned up to a height of 3 m. The diameter of each tree at 1.3 m height (DBH) was measured with a diameter tape and the tree height (h) with the help of a Forestor Vertex IV. During the pruning process the number of dead and living branches cut per tree was counted. The average DBH was 11.3 cm with a standard deviation of 0.8, and the mean tree height was 10.9 m with a standard deviation of 0.7. For every tenth pruned tree, all branches were measured in length and diameter. The genetic material planted in such a wide spacing showed a specific characteristic: there were one or two branches at the bottom of the tree with outstandingly large diameters (> 3 cm) for this stage of tree development. In this study, 38 out of 94 pruned trees (40%) showed this problem and were reported at data collection.

Having a closer look at the maximum diameters, the problem with the extremely big branches of this genetic material at this age, as mentioned before, becomes visible (Table 1). About 2/3 of these branches are already dead by the age of 18 months, even with a spacing of 5.0 m x 2.8 m. Based on information from the company, the wood of the branches of this genetic material is of elevated hardness. Up to today the problem is not reported, since the clone was developed for pulpwood production where the trees are planted in denser spacing and pruning is not taking part of the forest management strategy.

| Table 1. Branch data for the material used in the pruning experiment. The branch diameters were measured at every tenth pruned tree (N = 9), while the number of branches per tree was counted for every tree (N = 94). | ||||

| Mean | Min | Max | Stand. dev. | |

| Branch diameter (all, mm) | 17.8 | 7.3 | 50.7 | 5.9 |

| Living branch | 19.8 | 9.2 | 50.7 | 6.0 |

| Dead branch | 14.2 | 7.3 | 29.5 | 4.0 |

| N° of branches per tree | 29.1 | 14 | 46 | 4.2 |

The time study for evaluation of the productivity was conducted according to the guidelines of the German institution REFA (1998 and 2004, association for improving industrial engineering processes) and the theoretical instructions of Löffler (1992). These guidelines and publication were chosen because they are well adapted to forest work processes and are frequently applied in this context.

In a first step, three professional pruning tools frequently applied in forest practice were selected for the time study. As mentioned in the introduction, mainly handsaws and shears are used for high quality pruning of forest trees. The handsaw selected was the pruning saw used by the plantation-owning company, the LIMMAT C-47 (Fig. 1).

Fig. 1. Professional pruning saw LIMMAT C47 connected to a fix extension.

The saw is widely used in Brazil for high quality pruning of conifers and hardwoods. It has a total length of 650 mm, where the blade is 430 mm. The weight of the saw is 550 g. In practice, for the first pruning lift up to 3 m it is used with an extension of 1.50 m length with an additional weight of 1.5 kg. The manual pruning shear selected was Pro Pruner P100 (P100), which is also a widely used tool for professional pruning. Its total length is 665 mm and it can cut branches with diameters up to 65 mm. It weighs 1900 g and allows a pruning height of 2.5 m from the ground without additional tools. It is used more and more in pine plantations in Brazil to assure high pruning quality. As the third option, the electric pruning shear INFACO ELECTROCOUP F3010 (F3010) with the kit “medium” was selected. This electric pruning shear, originally developed for viniculture, has been adapted for cutting branches in forestry pruning activities. It comes with a battery pack and runs on 230 V and 50 Hz or 110 V and 60 Hz. The battery itself weighs 2400 g and is included in a jacket that the test person wears during work. The electronic control unit weighs 830 g and the shear, including the cables, has a weight of 640 g. The maximum branch diameter that can be cut with the Kit medium is 45 mm. Branches exceeding this diameter have to be cut off with other tools. The battery lasts for more than eight hours of work and needs about five hours to charge. The electric shear without any extension allows pruning lifts up to 2.1 m. The tool was introduced only recently on the Brazilian forestry market, therefore only a few experiences were made up to today. For branches exceeding the capacity of the shear, a handsaw was carried by the test persons and oversized branches were cut manually. To conduct the first pruning lift of 3 m in height as it is practiced in eucalypt plantations in Southern Brazil, an additional “step” was used. This tool is fixed around the tree with a chain and enables the operator to reach 1 m more of pruning height. The additional weight of the tool is 1600 g. For the work with the P100 shear, a step or a ladder is always needed. To reach 3 m in the pruning lift with the electric shear a carbon-fibre extension of 1 m length exists, but it was not available for the study. In practice the normal procedure would be the use of the extension to improve the performance of the tool. The saw is already used with an extension, so no additional tools were necessary.

The time study was conducted using the continuous reading method (Löffler 1992). The stop watch was counting continuously, and the time of each working cycle was noted. The time difference of the steps in the cycle was then analysed. The cycle contained between 2 and 5 steps, depending on the pruning tool: walking to the tree, pruning until the first lift, adjusting the step, pruning the second lift, and getting down on the ground and taking off the step. In the case of oversized branches for the F3010, the operators cut the branches manually with a handsaw. This time was taken apart for this tool; the time was stopped when the test person was standing on the ground again and had taken the step away. For the handsaw, only steps one and two were measured. The allocation base of this time study was one tree finished pruning up to a height of 3 m (first lift). Times for maintenance and pauses were also taken and calculated on a daily basis, assuming an 8 hour working day. Pausing time was decided individually by the forest workers according to their personal needs.

Besides the productivity, ergonomic aspects were taken into account as the workers have to deal with the technical devices every day, and ergonomics influence the productivity itself. The time study was carried out by two test persons, both of whom used each device twice for a period of 90 min. The first period was only for training purposes, ensuring that the person was able to handle the tool in a proper way, not using the data for any analysis. The 90 minute intervals were selected as representative because each test person worked 4 pruning units of 90 minutes at one day, summing up to a total of 6 working hours. Considering the lunch break of 1 hour required by law and the warm-up of the test persons of 15 minutes with the different tools before starting the time study, the total working time matched with an 8 hour working day. This arrangement avoided an excessive working rhythm during a 90 minute interval and simulates a real 8 hours working shift. Each test person worked for one day switching the tools after the working cycle. The sequence of the use of the tools was selected randomly, but both persons worked always parallel with the same tool. On the second day both test persons worked only for 2 working cycles. The tools were used after random selection in the following order:

- Cycle 1 (day 1): handsaw (training, only measurement of tree data)

- Cycle 2 (day 1): manual shears (training, only measurement of tree data)

- Cycle 3 (day 1): handsaw (full data collection)

- Cycle 4 (day 1): manual shears (full data collection)

- Cycle 5 (day 2): electric shears (training, only measurement of tree data)

- Cycle 6 (day 2): electric shears (full data collection)

Test person 1 was 45 years old, weighed 77 kg and was 1.81 m tall. Person 2 was 20 years old, weighed 72 kg and was 1.78 m tall. Both test persons have a professional background in forestry and are sportive. Nevertheless, neither of them was a professional pruner or field worker. Both test persons were trained by the equipment providers with the respective tools and acquired sufficient skills to do the pruning operations with a routine. It was opted not to take professional pruners for the test, since there were no persons available with training on all the pruning tools used in the experiment and theoretical background on high quality pruning for sawlog production.

The heartbeat rate was measured with a POLAR pulse watch S810 using the corresponding pulse belt fixed at breast height on the test persons. The belt sends the heartbeat rate to the watch, from where the data can later be transferred to a computer for analysis and interpretation. A 15-minute warm-up period was considered in each working cycle before taking the time and productivity data for analysis. The heartbeat data were measured for each technical pruning device and for each test person. Before starting the experiment, the relaxed pulse of both test persons was detected after Löffler (1992) in two different sessions. For determination of physical workload with the three devices, Löffler (1992) explains, referring to Buchberger and Fahrni (1990), different stages of the labour and their level of difficulty. He defines the “working heartbeat rate” as the sum of the differences between the relaxing heartbeat and the heartbeat measured while working. This value is correlated to the level of physical and mental workload of the labour. He divides labour into very easy (up to 15 bt/min of “working heartbeat”), easy (16–30), middle hard work (31–45), hard work (46–60), very hard work (61–75) and utmost hard work (over 75). The method allows the elimination of heartbeat trends which are due to individual differences of physical and mental fitness of the test persons. The “relaxing heartbeat” or “resting heartrate” was measured while the test person was relaxed but awake, in a neutrally temperate environment, and not having recently exerted himself to a stress. Two seasons of 15 minutes were taken with the same equipment for each test person to get the average resting heartrate.

Since forestry work is typically an outdoor activity, exposing its workers to the prevailing climate conditions, the data during the study period need to be presented. The average yearly air temperature ranges between 15 and 18 °C, while minimum temperature may reach –4 °C (July and August) and the maximum 40 °C (January and February). During daytime the temperature always is above 0°C. There is no specific pruning season, the operations are carried out all over the year.

The first day of the time study was rainy in the morning with a temperature of 20 °C and cloudy in the afternoon with a temperature of 22 °C. The second day of the time study was sunny, starting in the morning with a temperature of 24 °C and rising to 30 °C in the afternoon. While on the first day the climate might be classified as “uncomfortable” because of high relative humidity, on the second day breath and heartbeat rate could be expected to be higher because of increased body temperature of the test persons (Rodgers 1983). In this study the influence of climate on heartbeat was not considered, since the conditions are very difficult to control and require at least a middle to long term experiment to obtain statistically representative results.

The number of trees pruned by the test persons varied within the 90 min time study due to the different devices used, the physical fitness of the test persons, and the number and size of branches per tree. The pruning height of 3 m in this time study was the height estimated by the test persons as is the practice of pruning teams of forest workers.

A scientific approach of evaluating pruning quality was not applied. The only controlling that happened was conducted by the forest engineer of the company which is in charge of supervising the pruning activities of the forest workers. After pruning it is checked if the remaining stubs of the cut branches fulfill the quality requirements of the company and if pruning height of 3 m was kept. The trees pruned in the experiment were accepted according to the quality requirements of the company.

For statistical analysis of the results the software SAS 9.1 and Excel 2010 were used. For evaluating the productivity, a correlation analysis between the pruning time needed for an individual tree and the branch variables was performed. Prior to analysis the values were transformed into relative units. The average total pruning time needed per tree with every tool was set to 100% and the absolute individual values measured were related to this mean value. The ergonomic data were standardized after the method of Löffler and the respective descriptive statistics calculated.

3 Results

3.1 Productivity of different pruning tools

A correlation analysis showed that Pearson’s coefficient of correlation was highly significant for pruning time per tree and the number of branches as well as for branch diameter, but the coefficients themselves were rather low, at 0.41 and 0.46, respectively.

The results for the time study and the individual tools showed significant differences for the three pruning tools used in the study (Table 2).

| Table 2. Average pruning time per tree and test person (TP) for the pruning tools used in the experiment, excluding maintenance and pausing time (only second pruning period). | ||||||||

| Tool | 1st pruning lift (min) | 2nd pruning lift (min) | Step (min) | Total time (min) | ||||

| TP 1 | TP 2 | TP 1 | TP 2 | TP 1 | TP 2 | TP 1 | TP 2 | |

| LIMMAT | 2:17 | 2:18 | - | - | - | - | 2:17 | 2:18 |

| F3010 | 1:24 (0:08 a)) | 1:22 (0:07 a)) | 0:18 | 0:15 | 0:19 | 0:22 | 2:01 | 1:59 |

| P100 | 1:50 | 1:55 | 0:11 | 0:12 | 0:21 | 0:20 | 2:22 | 2:27 |

| a) Average time per tree used for cutting oversized branches with handsaw. | ||||||||

For the change from tree to tree, according to the spacing a distance in the line of 2.8 m, a joint average of 13 seconds for all pruning tools was calculated. The differences measured in this step were not significant among the tools used in the study. The maintenance time for the handsaw LIMMAT was taken according to the information given by the company. The saw blade is cleaned and sharpened once a week, which takes approximately 1% of the weekly working time (40 hours), which corresponds to 24 minutes per saw per week. For the maintenance of the F3010, a time of 3 minutes every hour was set for sharpening and applying grease, summing up to 24 minutes a day, corresponding to 4.5% of the working time. This is a higher maintenance frequency than recommended by the manufacturer, but the high tannin contents of the eucalypts, the hard branch wood, and the rainy conditions during the study time made it recommendable in order to keep full productivity of the tool. For the P100, sharpening and cleaning was conducted every 4 working hours, taking about 5 minutes (Fig. 2).

Fig. 2. Cleaning and sharpening of the P100 Pro-Pruner pruning shear after use in a pine stand.

This is double the maintenance frequency recommended by the manufacturer, but the same arguments apply as for the F3010. Ten minutes per day add up to a maintenance time of 2.1% of total working time. The time paused in a 90-minute working session was not significantly different for the LIMMAT handsaw and the P100. It added up to 4.6 and 4.7%, respectively. The pausing time for the F3010 was lower, at only 3.8%. From these data, a total productivity based on an 8-hour working day may be calculated (Table 3). As there exists an extension of 1 m length for the F3010, for this tool a “virtual” option of taking off the step was calculated. For the pruning shear P100, the pruning productivity up to a 1st pruning lift of 2.5 m was calculated, also without the use of a step.

| Table 3. Productivity of different pruning tools compared to that of the LIMMAT handsaw. (*including maintenance and paused time; **handsaw as most commonly used tool in practice set equal to 100% of productivity; ***calculated value (by subtracting 0.2 min of the step tool) assuming that the 1 m extension available for the F3010 has the same productivity as the use without the additional tool). | ||

| Real productivity* trees/ha | Productivity** compared to handsaw | |

| LIMMAT C47 | 180 | 100% |

| F3010 | 200 | 111% |

| F3010 with extension*** | 236 | 131% |

| P100 | 171 | 95% |

| P100 without step (2.5 m) | 196 | 109% |

The productivity with the LIMMAT C47 handsaw in the present study was 180 pruned trees per 8-hour working day. This tool is the most frequently used in forestry practice in Southern Brazil, so it was taken as the standard for productivity and set to 100%. Compared to this value, the productivity achieved with the electric shear F3010 was 11% higher and for the manual shear P100 about 5% lower (Fig. 3).

Fig. 3. Pruning of 18 month old eucalypts with P100 Pro-Pruner shear. The forest workers have to use personal protection equipment consisting of closed boots, snake protection, helmet, gloves and eye protectors.

With the 1 m extension without a step, the productivity of a pruning lift up to 3 m would be 31% higher than for a comparable lift with the handsaw. The restriction in productivity for the P100 is clearly the use of the step for the missing 50 cm of pruning height.

Therefore, a virtual productivity was calculated for a pruning lift where no step is needed, which resulted in a 9% higher productivity compared to the handsaw.

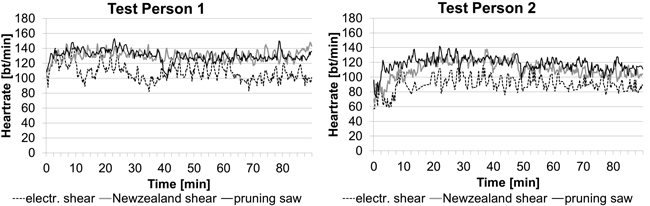

3.2 Ergonomy of the analysed pruning tools

After the analysis of the productivity of the pruning tools a basic evaluation of ergonomic aspects was conducted. The heartbeat rates (in bt/min) of the two test persons show significant differences for the three different tools (Table 4). Even so, the trends for the tools are almost the same: the lowest bt/min ratio was found with the electric shear F3010, followed by the manual shear P100 and the handsaw LIMMAT C47. But the levels of the heartbeat rate are clearly different. On average, the pulse of the younger test person (person 2) was 16 beats lower than that of test person 1. The same can be noted for the maximum value, which was 15 bt/min higher.

| Table 4. Heartbeat rate for the two test persons (TP) and the three pruning tools used in the study. In brackets: lower case letters indicate significant differences in the mean values of the used tools for each test person after the Tukey test; upper case letters indicate significant differences of the mean values between the test persons (Tukey test). | ||||||

| TP1 F3010 | TP1 P100 | TP1 LIMMAT | TP2 F3010 | TP2 P100 | TP2 LIMMAT | |

| MEAN [bt/min] | 108(aA) | 129(bA) | 130(bA) | 90(aB) | 111(bB) | 118(bB) |

| MIN [bt/min] | 82 | 106 | 101 | 65 | 65 | 73 |

| MAX [bt/min] | 141 | 148 | 153 | 116 | 138 | 142 |

| Starting heartbeat [bt/min] | 108 | 106 | 109 | 73 | 70 | 96 |

The mean values give a first impression about the workload of each pruning tool, but the heartbeat frequency over the whole working period of each tool is important for a detailed analysis (Fig. 4). The heartbeat rates of both test persons using the F3010 tool were always under the level of the handsaw and the manual shear P100, showing that the workload of this tool is significantly lower. The P100 and LIMMAT C47 are not significantly different in terms of the workload (Table 4). Even so, there are obvious differences between the physical fitness and therefore the heartbeat rates of the 2 test persons (Fig. 4).

Fig. 4. Heartbeat rate measured for the two test persons using the three different tools (test person 1 = 45 years old, test person 2 = 21 years old)

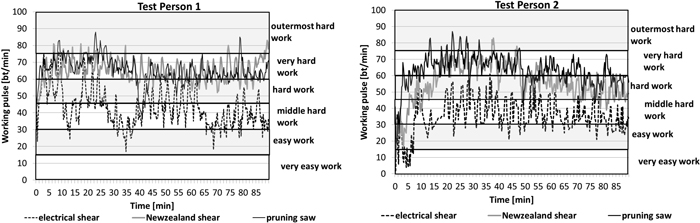

To eliminate the difference in the levels, the method described as follows after Löffler (1992) was applied. The resting pulse was subtracted from the real measured heartbeat per minute to obtain comparable pulse levels between the two test persons (Fig. 5). The classification in workload levels allows a comparison between the test persons without the age trend. It must be stated that for the P100 and the LIMMAT C47 both test persons worked most of the test period at the level of “very hard work”, while for the F3010 they ranged between “middle hard work” and “hard work”. Test person 2 shows a better adaptation to the work during the measurement period, resulting in a smooth decrease of the heartbeat rate after the first 45 minutes (Fig. 5).

Fig. 5. Heartbeat rates of the two test persons after subtracting the resting pulse and classification of “workload zones” (test person 1 = 45 years old, test person 2 = 21 years old)

It must be noted that the use of the step is still included in the pulse data of the working sessions of the F3010 and the P100. The use of the tool is one of the reasons for the strong heartbeat oscillation in the graphs of the electric shear and the manual shear. To climb up the step requires a strong physical effort by the test persons, as can be seen in the peaks of the graphs (Fig. 5, Fig. 6).

Fig. 6. Use of the tools P100 Pro Pruner (left) and the electric shear F310 (right) for a first pruning lift up to 3 m height. For this activity a step had to be used, influencing on productivity and ergonomics of the tools.

4 Discussion

The productivity of the pruning tools used in this study may not match 100% with data of forestry practice. First, the two test persons were not forest workers with long-term training and second, pruning was conducted with strong emphasis on pruning quality. The latter is often sacrificed for a higher productivity, where the branch collars are cut or the stem wood is hurt by inadequate use of the handsaws. This cannot happen using pruning shears, because the construction of this tool simply does not allow the worker to get that close to the stem of the tree. Based on information from the company, the average of 180 trees per 8-hour working day with the handsaw LIMMAT C47 is not much below their own experience, considering the problems of big and hard branches caused by the spacing and genetic material. The productivity reached with the P100 may be considered as comparable to the handsaw, showing the big disadvantage that for a 3 m lift an additional tool such as a “step” or a ladder has to be used, causing additional workload and reducing productivity. In a case study of Kirk and Parker (1995), the average productivity of six forest workers was 92 trees pruned per day for a first pruning lift of 2 m, which is much lower than the productivity found in this study and also lower than the average reached by forest workers in pruning operations in Southern Brazil. Even so, some experts in forestry practice and researchers prefer shears because of their much better pruning quality (Stackpole 2001). Especially for bigger branches and high quality wood production there are advantages in the cicatrisation process: less rottenness and faster occlusion of the wound (Wardlaw and Neilsen 1999). These issues were not investigated in this study but may be an argument in favour of the shears. The productivity of the electric shear F3010 is clearly superior to that of the purely manual tools, even with higher maintenance time. An extension for the shear offers an interesting perspective towards even more efficient pruning. Anyhow, in the case of this study a combination of F3010 and handsaw had to be used because of excessive branch diameter. Often, the opening of the shear was big enough, but the electric engine in some cases showed limitations, also due to the cited hard wood of the eucalypt branches. On the other hand, the cut that has to be made for pruning a branch is bigger than the branch diameter, since the steeper the branch angle the bigger the cutting area. Koenig (2005) found for Eucalyptus grandis that the scar length was on average about 18% bigger than the branch diameter. Another factor influencing productivity was the curved growth of the branch at its base, because the branches that sprouted in the line turned to grow after the light between the planting rows. In this case it was difficult to put the tools in the right position to give a qualitatively good cut. If an extension is used for the electric shear, productivity can even be increased, as the calculations that ignored the time needed for putting on and taking off the step showed. Quality can also be improved, as the worker has more freedom to position himself than is the case when he must stay on the step.

In terms of ergonomics, the purely manual tools lead to a high workload that reaches the level of the upper physical and mental limits of the human body. In fact this is the case for the forest workers permanently working in this job. Based on an interview with the company, each worker is absent for two days per month, on average, because of muscle pain and generally bad physical conditions, a clear indicator of an extremely hard workload. In terms of ergonomics there is an urgent need to reduce the workload for the human body during pruning operations (Kirchner and Baum 1986). There are also the subtropical climate conditions to consider. During the experiment there were warm and humid weather conditions. After Rodgers (1983), high relative air humidity causes extremely uncomfortable working conditions, leading to higher heartbeat rate and increased body temperature. Also, Smith et al. (1985) state that the “heart rate is known to increase as the temperature increases”. Additionally, fluid consumption during the pruning progress has an effect on the human body. On sunny days more intervals for drinking are necessary to keep full working capacity. The study of Wästerlund et al. (2004) took place at temperatures of 7.8 and 22.5 °C. They found an effect on the working efficiency of the workers by using a high and low fluid scheme. The high fluid scheme resulted in a lower heartbeat by keeping a comparable productivity of the forest workers. Since the two test persons worked in 90 min shifts, enough fluid consumption was given in the breaks, although it has to be taken into account that the study took place on days with higher temperatures than the study of Wästerlund et al. (2004). Even so, the results of the study may be biased by the fact of the second day was warmer. This may have influenced the heartbeat rate of the test persons while working with the electric shear. As mentioned before, the experimental design of the study does not allow any conclusions about effect of climate conditions.

Another important issue to be mentioned is the nutritional status of people of lower social classes, who are mainly doing the hard forest work. The living standard in general is lower, and the daily caloric consumption is limited by income or local customs. All this may lead to a slow but continuous degradation of the individual working capacity if the daily workload remains on a “very hard work” level (Löffler 1992).

The hand saw LIMMAT C47 with the 1.5 m extension is a tool already optimised for a 3 m pruning lift. The weight is acceptable for a normal worker, and due to the extension it is not necessary that the worker bend down to cut the lower branches of the stem, and also the work at 3 m height can be done in an upright position. The pruning saws are always working on pull, bearing the risk of pulling the branches down instead of cutting them when the worker gets tired. The shears on the other hand need more training for correct use, but the technology itself in general causes less workload on the operator. The authors assume that the P100 heartbeat rate is only at the level of the handsaw because of the use of the step, which always causes increased physical activity when climbing up. Kirk and Parker (1995) found an average heartbeat rate of 112 for a manual shear similar to the P100 without using a “step”. As the first day of the study was rainy in the morning, the stems of the trees were wet and slippery. This had an effect on the step, because the step itself did not always stay at the right position and slid down to the ground. This meant an extra lift of the step to its right position by the probands, which affected the heartbeat rate and the productivity of the work with the shears.

The genetic material selected for the pruning test was described by the forest company as one of the most difficult to prune and with the lowest productivity of the pruning process of their forest operations. It was purposely chosen by the authors, as the differences in the results become more significant when material and humans get closer to their limits. The productivity results may therefore not be comparable to other studies or realities found in other eucalypt plantations, but for the present study they are conclusive.

The pruning tools used in the study are already applied in South American plantations. In practice, the shears were used less in the past, but an increasing trend can be noted in the use of these tools. The real potential of the tools and which of the tools is more appropriate for use in high-quality pruning can only be decided if economic and quality aspects are included in the analysis. A very important and often cited issue is the comparison of pruning quality between saws and shears. On the other hand, the cost factor must also be considered, because the use of electric tools like F3010 implies higher investments for purchasing and increased maintenance costs.

References

Alcorn P.J., Pyttel P., Bauhus J., Smith G.R., Thomas D., James R., Nicotra A. (2007). Effects of initial planting density on branch development in 4-year-old plantation grown Eucalyptus pilularis and Eucalyptus cloeziana trees. Forest Ecology and Management 252: 41–51. http://dx.doi.org/10.1016/j.foreco.2007.06.021.

Bernmark E. (2011). Measurement of physical workload with special reference to energy expenditure and workposture. Dissertation. Karolinska Institutet, Stockholm.

Buchberger J., Fahrni M. (1990). Arbeitsbedingungen und gesundheitliches Befinden – Beurteilung durch Erwerbstätige in der Schweiz. Biga-Verlag, Schweiz.

Caliskan E., Caglar S. (2010). An assessment of physiological workload of forest workers in felling operations. African Journal of Biotechnology 9: 5651–5658.

Gerrand A.M., Neilsen W.A., Medhurst J.L. (1997). Thinning and pruning eucalypt plantations for sawlog production in Tasmania. Tasforests 9: 15–34.

Henskens F.L., Battaglia C.L., Cherry M.L., Beadle C.L. (2001). Physiological basis of spacing effects on tree growth and form in Eucalyptus globulus. Trees – Structure and Function 15: 365–377.

Kirchner J.H., Baum E. (1986). Mensch-Maschine-Umwelt. Ergonomie für Konstrukteure, Designer Planer und Arbeitsgestalter. Berlin-Köln, Beuth Verlag.

Kirk P.M., Parker R.J. (1995). Heart rate strain in New Zealand manual tree pruners. International Journal Industrial Ergonomics 18: 317–324. http://dx.doi.org/10.1016/0169-8141(95)00089-5.

Koenig C. (2005). Optimizing the production of high value timber in fast growing eucalyptus plantations in Brazil – efficiency and economic impact of pruning. Master’s thesis. University of Freiburg, Freiburg, Germany.

Löffler H. (1992). Leitfaden zu den Lehrveranstaltungen Arbeitswissenschaft für Studierende der Forstwissenschaft. 3. Aufl. ed. University of München, München.

Medhurst J.L., Beadle C.L., Neilsen W.A. (2001). Early-age and later-age thinning affects growth, dominance, and intraspecific competition in Eucalyptus nitens plantations. Canadian Journal of Forest Research 31: 187–197. http://dx.doi.org/10.1139/x00-163.

Montagu K., Kearney D., Smith G. (2003). Pruning eucalypts – the biology and silviculture of clear wood production in planted eucalypts. Rural Industries Research and Development Corporation (RIRDC).

Nutto L., Touza Vázquez M.C., Delgado J.L. (2003). Producíon de madera de calidad de eucalipto: La poda – conocimientos fundamentales y técnicas. CIS-Madera 11: 35–45.

Pinkard E.A., Beadle C.L. (1998). Effects of green pruning on growth and stem shape of Eucalyptus nitens (Deane and Maiden) Maiden. New Forests 15(2): 107–126. http://dx.doi.org/10.1023/A:1006533423884.

REFA (1998). Arbeitsstudien, Arbeitsorganisation und Qualitätsmanagement in der Forstwirtschaft. REFA-Fachausschuss Forstwirtschaft, Stuttgart, Germany.

REFA (2004). Organisation in der Forstwirtschaft – mit REFA zu effizienten Methoden. REFA, Weinheim.

Reid R. (1999). Have you got too many trees? A case for thinning hard and early in eucalypt plantations for sawlogs. Agricultural Notes 0774. Tasmania, Australia.

Rodgers S. (1983). Ergonomics design for people at work. Vol. 1. Workplace, equipment, and environmental design and information transfer. Edited by Elizabeth Eggleton for Eastman Kodak Company. Van Nostrand Reinhold, New York.

Schönau A.P.G. (2002). The effect of planting spacement and pruning on growth, yield and timber density of Eucalyptus grandis. South African Journal of Forestry 88: 16–23. http://dx.doi.org/10.1080/00382167.1974.9629319.

Smith L.A., Wilson D.G., Sirois D.L. (1985). Heart-rate response to forest harvesting work in the south-eastern United States during summer. Ergonomics 28: 655–664. http://dx.doi.org/10.1080/00140138508963179.

SFB and IMAZON (2010). A atividade madeireira na Amazônia brasileira: produção, receita e mercados. Rep. CDD: 333.7509811.

Stackpole D. (2001). Eucalypt stem pruning. Agriculture Notes AG0773. Tasmania, Australia.

Wardlaw T.J., Neilsen W.A. (1999). Decay and other defects associated with pruned branches of Eucalyptus nitens. Tasforests 11: 49–57.

Washusen R., Waugh G., Vinden P., Hudson I. (2000). Appearance product potential of plantation hardwoods from medium rainfall areas of the southern Murray-Darling Basin. Green product recovery. Australian Forestry 63: 66–71. http://dx.doi.org/10.1080/00049158.2000.10674815.

Wästerlund D.S., Chaseling J., Burström L. (2004). The effect of fluid consumption on the forest workers’ performance strategy. Applied Ergonomics 35: 29–36. http://dx.doi.org/10.1016/j.apergo.2003.09.002.

Total of 25 references

Send to email