Forest operations during continuous cover forestry in the Nordics: the need for cost-efficient harvesting solutions like single-machine systems

Ersson B. T., Manner J., Kärhä K. (2025). Forest operations during continuous cover forestry in the Nordics: the need for cost-efficient harvesting solutions like single-machine systems. Silva Fennica vol. 59 no. 3 article id 25044. https://doi.org/10.14214/sf.25044

Highlights

- Low harvest volumes per tract decrease the cost-efficiency of today’s conventional logging systems

- Single-machine systems (SMS) like harwarders and dual machines are competitive when harvested volumes are low, for example during harvesting in continuous cover forestry (CCF)

- As CCF grows in the Nordics, so does the need for development and commercialization of SMS that can harvest large trees.

Abstract

Low tract size (ha) and harvested volume per hectare (m3 ha–1) decrease the cost-efficiency of today’s conventional Nordic harvesting systems, which generally consists of a harvester and a forwarder. Low cost-efficiency is a problem because it reduces forest owners’ incentive to harvest wood and manage their forests. Today’s conventional harvesting system (two-machine system; TMS) was developed based on rotation forest management. As continuous cover forestry (CCF) grows in the Nordics, it is necessary to develop harvesting solutions that can operate cost-efficiently even when total removal (m3 per tract) is low. Single-machine systems (SMS) require only one machine to do all the harvesting activities; thus, SMS have only one machine-relocation cost per tract, instead of two per tract for TMS. SMS are generally categorized as either harwarders or dual machines, the difference being if the machine processes the logs directly onto the load space or not. In relation to TMS, the relative competitiveness of SMS increases with decreasing tract size, harvested volume per hectare, and/or average extraction distance. Because of site adaptation, CCF, and ever-expanding forest road networks, the trend in Nordic forestry over the last few decades has been that these three factors have been decreasing. CCF mainly entails thinning from above, which generally means the harvesting of large trees. SMS exist today, but almost exclusively as small-sized dual machines that cannot cut large trees. Thus, there is a pronounced need for commercially available SMS that can fell and process large trees.

Keywords

boreal forest;

logging;

harwarder;

combi machine;

dual machine;

harvester forwarder;

two-machine harvesting system

-

Ersson,

SLU, School of Forest Management, SE-739 21 Skinnskatteberg, Sweden

https://orcid.org/0000-0003-2442-7482

E-mail

back.tomas.ersson@slu.se

https://orcid.org/0000-0003-2442-7482

E-mail

back.tomas.ersson@slu.se

-

Manner,

Skogforsk, Uppsala Science Park, SE-751 83 Uppsala Sweden

https://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

https://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

- Kärhä, School of Forest Sciences, University of Eastern Finland (UEF), P.O. Box 111, FI-80101 Joensuu, Finland E-mail kalle.karha@uef.fi

Received 2 September 2025 Accepted 11 November 2025 Published 18 November 2025

Views 9608

Available at https://doi.org/10.14214/sf.25044 | Download PDF

1 Background: removal per tract is decreasing

Interest in continuous cover forestry (CCF) is growing in Nordic boreal forestry (Cedergren et al. 2025). The growth is especially rapid in Finland; likely because a large proportion of Finnish productive forestland is privately owned and CCF is popular among private forest owners (Luke 2025). Moreover, Swedish and Norwegian certification schemes nowadays oblige an increased use of CCF on certified forest holdings. However, the harvested volume per hectares (m3 ha–1) is typically lower during CCF compared to rotation forest management (RFM), i.e. conventional Nordic clearcut forestry (Korpunen et al. 2025). Concurrently, average tract size (in ha) has decreased over the last decades in Sweden (Skogsstyrelsen 2024). Meanwhile, in Finland, tract sizes increased during 1980–2010. That said, tract sizes in Finland are relatively small, being on average only around 500 m3 (Hänninen et al. 2011). Trends in Norway remain unclear.

Together, these trends jointly erode the cost-efficiency of today’s conventional cut-to-length harvesting system (two-machine system; TMS) because each tract then produces less volume (m3 per tract) to spread out fixed costs upon (Kärhä et al. 2007). Such fixed costs include planning costs and especially relocation costs including the machine downtime associated with relocating. Decreasing cost-efficiency during logging is a problem because it reduces forest owners’ incentive to harvest wood, manage their forests, etc. Since the TMS was originally designed around the principles and harvesting volumes characteristic of RFM, its application under emerging CCF paradigms (with lower removals per tract) appears suboptimal. These trends underscore the need to develop harvesting solutions that can operate cost-efficiently even when total removal (m3 per tract) is low.

2 Harvesting methods in boreal CCF

Exact definitions of CCF vary among countries. In Norway and Sweden, CCF comprises three types of harvesting methods: selection cutting, gap cutting and shelterwood cutting. Meanwhile, in Finland, CCF comprises only selection cutting and gap cutting (Cedergren et al. 2025). During selection cutting, the distance driven between harvested trees increases when compared to RFM (Spinelli and Magagnotti 2013). During gap cutting (sometimes also termed patch cutting; Eliasson et al. 2021), driving distances during extraction increase when compared to RFM. Gap cutting entails creating mini-clearcuts; small, discrete clearcuts that are spread out in the stand, the most extreme form of gap cutting being checkerboard cutting (Erefur 2010). These mini-clearcuts lead to decreased roundwood removal per hectare (m3 ha–1, or more specifically m3 per 100 m strip road; generally termed log concentration) which in turn leads to longer driving distances during extraction compared to RFM (Hildt et al. 2020). Overall, compared to clearcutting, total removal per ha decreases during shelterwood cuttings (Eliasson et al. 1999), during gap cutting (Eliasson et al. 2021), and during selection cutting (Jonsson 2015). This fact is a result of the above-mentioned CCF silvicultural systems leaving more trees in the forest after harvesting, which of course is the essence of the CCF concept.

3 Single-machine systems (SMS)

SMS require only one machine to do all the logging activities, including cutting and terrain transporting (Talbot et al. 2003). In comparison, TMS uses a harvester for the cutting and a forwarder for the terrain transport. Thus, SMS have only one machine-relocation cost per tract, instead of two machine-relocation costs per tract for TMS. In Nordic forestry, machine-relocation costs can be a significant expense, typically averaging around 400 euros per machine per tract in Sweden today (Table 1). As such, the total relocation cost per tract for Swedish TMS typically averages €800, which tallies to €8 m–3 if the total removal at a tract is 100 m3 (38% of total logging costs). In comparison, that relocation cost would be €4 m–3 for SMS (24% of total logging costs): a significant saving seeing that total harvesting costs typically average around €10 m–3 during final felling in Finnish RFM, around €13 m–3 in Swedish conditions, and around €18 m–3 in Norwegian conditions. In the early 2000s, relocation costs could comprise up to 10% of total logging costs for TMS in Finland, but a newer study by Väätäinen et al. (2021) shows that the relocation costs’ share of total Finnish logging costs has decreased during the last decade.

| Table 1. Costing example for single-machine systems (SMS) versus two-machine systems (TMS) on small tracts in Sweden. In this example, the assumed relocation cost per tract per machine was €400. The logging cost was assumed to equal the Swedish national average for clearcutting during 2023. | ||||||

| Machine system | Tract size / Volume per harvesting site (m3) | Total relocation cost per machine system (€) | Relocation cost (€ m–3) | Logging cost (€ m–3) | Total logging cost including relocation (€ m–3) | Relocation costs’ share of total logging costs (%) |

| SMS | 50 | 400 | 8 | 13 | 21 | 38 |

| 100 | 400 | 4 | 13 | 17 | 24 | |

| 200 | 400 | 2 | 13 | 15 | 13 | |

| 300 | 400 | 1.33 | 13 | 14.33 | 9 | |

| 400 | 400 | 1 | 13 | 14 | 7 | |

| TMS | 50 | 800 | 16 | 13 | 29 | 55 |

| 100 | 800 | 8 | 13 | 21 | 38 | |

| 200 | 800 | 4 | 13 | 17 | 24 | |

| 300 | 800 | 2.66 | 13 | 15.66 | 17 | |

| 400 | 800 | 2 | 13 | 15 | 13 | |

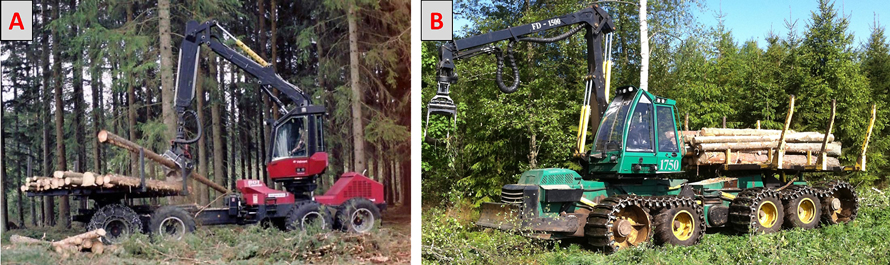

SMS are generally categorized as either: i) harwarders (Fig. 1A), or ii) dual machines (also called harvester-forwarders or combi machines; Fig. 1B), the difference being if the machine processes the logs directly onto the load space or not. Harwarders can process the logs directly onto the load space, which is sometimes termed direct loading (Ringdahl et al. 2012). Previous examples of harwarders include: the Hemek harwarder (Wester and Eliasson 2003); the Pika 828 (Sirén and Aaltio 2003; despite being a harwarder, the Pika 828 was unfortunately termed harvester-forwarder in that study); the Valmet 801 Combi (Ström 2008; despite being a harwarder, the machine was unfortunately named Combi); the Fibredrive 1750 prototype; and the Komatsu X19 prototype (Lundqvist 2023). In contrast, a dual machine initially works as a normal harvester and processes the logs into piles on the ground (Talbot et al. 2003). Thereafter, the dual machine converts into a forwarder, loads the logs from the ground, and forwards them to the landing. The foremost example of dual machines in Nordic forestry is the Ponsse Dual. The Ponsse Dual has been frequently studied since the turn of the millennium (e.g. Talbot et al. 2003; Hallonborg et al. 2005; Affenzeller and Stampfer 2007; Kärhä et al. 2007). Notwithstanding, harwarders can also work as dual machines if the operator chooses not to direct load. For example, Kärhä et al. (2018) studied both the Ponsse Dual and the Valmet 801 Combi harwarder; and in that study, all machines worked as dual machines despite unfortunately always being termed harwarders. It has also been hypothesised that a SMS (harwarder or dual machine) could be useful in combination with yarding (Talbot 2016).

Fig. 1. Previous examples of large single-machine systems (LargeSMS): A) harwarder (Komatsu X19 prototype during unloading using a loading grapple); B) dual machine (Ponsse Buffalo Dual in harvester mode). A harwarder processes the logs directly onto the machine’s load space (termed direct loading), while a dual machine initially works as a normal harvester and processes the logs into piles on the ground. Thereafter, the dual machine converts into a forwarder, loads the logs from the ground, and forwards them to the landing. Photos: Rikard Lundqvist (A) and Ponsse Plc (B).

4 Factors affecting the cost competitiveness of SMS

Because of the higher capital costs of SMS (each machine must have a bunk/load space, a grapple, and a harvesting head), the hourly cost of SMS is higher than of standard forwarders. Thus, for SMS to be competitive in relation to TMS, the proportion of forwarding work compared to harvesting work must not be too high. Thus, SMS are more competitive when extraction distances are short (Sirén and Aaltio 2003; Kärhä et al. 2007). Average extraction distance in Sweden is steadily decreasing, mainly because of an ever-expanding forest road network (Bergqvist et al. 2023). This trend in average extraction distances is true for at least Sweden, and this trend is an advantage for SMS’ competitiveness versus TMS. The trend is unclear in Norway, despite an ever-expanding forest road network (Statistics Norway 2025). The trend in average extraction distances is also unclear in Finland, despite an ever-expanding forest road network that averages 7.7 m per hectare of forest (Väätäinen et al. 2025).

Frequent relocation of forest machines reduces machine utilization (MU), which also increases logging costs (Talbot and Suadicani 2015). Small tracts lead to frequent relocations. Ceteris paribus, frequent relocations decrease the MU of highly productive logging systems more than of lesser productive systems (Bergkvist 2010). Because each relocation consumes several machine hours on average, the more relocations, the more partial days occur (during which fixed costs still apply; Kärhä et al. 2007). With SMS, the risk of partial days is essentially halved compared to TMS, assuming that the productivity rate of one SMS is half of one TMS (Ringdahl et al. 2012). This issue remains even when small tracts are bundled into a larger tract i.e., wheeling between tracts reduces the problem of trailer costs for small tracts, but the issue of low MU persists.

Forwarders’ loading-driving time increases drastically with decreasing roundwood removal per hectare (Hildt et al. 2020). Because harwarders generally load the logs already during cutting, harwarders are only to a lesser extent affected by decreasing roundwood removal per hectare. Therefore, because of direct loading, harwarders have a relative advantage compared to TMS and dual machines when roundwood removal per hectare is low, e.g. in CCF and especially selection cutting. The drawback with direct loading is that unloading can be slower, especially when there are many assortments.

Another important productivity factor is the number of assortments produced at the tract. Compared to both TMS and dual machines, the relative competitiveness of harwarders decreases with increasing number of assortments (Hallonborg 1998; Kärhä et al. 2007). This circumstance is because of direct loading, and the impossibility of harwarder operators to choose which assortments are loaded per load. Because TMS and dual machines do not use direct loading, operators of TMS and dual machines can choose which assortments are forwarded per payload. The main disadvantage of direct loading was previously thought to be mitigated, for example, by dividing the load space into multiple, flexible compartments; however, this technical solution has at times shown to be impractical during processing (Jonsson et al. 2020).

Today, there exists multiple solutions for quick coupling grapples and harvester heads onto forestry cranes/boom-tips (Fig. 2). Quick coupling technology increases the competitiveness of SMS compared to TMS by reducing the time needed to switch between harvesting heads and loading grapples on both harwarders and dual machines. This reduction in time consumption allows for more efficient work methods and/or raises the SMS’ machine utilization. Previously, there existed combined harvesting-grapple heads (Bergkvist et al. 2002), but they have been shown to be inefficient, especially during unloading (Jylhä et al. 2006). Quick coupling is now so widespread that it most certainly will become standard technology in future SMS. This technological development makes the MU-values from older SMS studies less relevant today.

Fig. 2. Examples of quick coupling technology on: A) the Komatsu X19 harwarder prototype and; B) the Fibredrive 1750 harwarder prototype. Quick coupling technology increases the competitiveness of single-machine systems (SMS) compared to two-machine systems (TMS) by reducing the time needed to switch between harvesting heads and loading grapples on both harwarders and dual machines. This reduction in time consumption allows for more efficient work methods and/or raises the SMS’ machine utilization. Photos: Rikard Lundqvist (A) and Back Tomas Ersson (B).

Since about the turn of the millennium, harwarders have been using rotatable and tiltable load spaces/bunks (Fig. 3). These types of bunks allow for efficient direct loading, energy-efficient loading (Dong et al. 2019), efficient unloading (Jonsson et al. 2016), and semi-automation on SMS (Manner et al. 2019). Disadvantages of rotatable and tiltable bunks are higher capital costs, higher center of mass, slightly lower load capacity, slightly wider strip road requirements during thinning, more complicated maintenance, and higher risk of mechanical failure (Jonsson et al. 2020). Nevertheless, because rotatable and tiltable load spaces facilitate efficient direct loading, these bunk types are an essential technical innovation for cost-competitive harwarders.

Fig. 3. Rotatable and tiltable load spaces/bunks on previous SMS (Valmet 801 Combi harwarder and Fibredrive 1750). These types of bunks allow for efficient direct loading, efficient unloading, and semi-automation on SMS. Photos: Skogforsk (A) and Back Tomas Ersson (B).

5 The need for large SMS

CCF is growing in Nordic forestry, and CCF often entails thinning from above, which generally means the harvesting of large trees (Korpunen et al. 2025). Thus, forest machines in CCF must be large and strong enough to fell and process large trees >1 m3 in piece size.

SMS exist today, but almost exclusively as small-sized dual machines. Examples are Vimek Duo, Terri 3CW, Malwa 560C Kombi, Jarcrac Magnapro Dual and Alstor 850 Kombi (Boson 2025). We hereafter term these types of SMS machines “SmallSMS”. SmallSMS cannot fell large trees, which disqualifies today’s commercially available SmallSMS from being widely used during harvesting in Nordic boreal CCF stands. There is thus a pronounced need for commercially available SMS that can fell and process large trees without damaging the remaining stand (i.e. large single-machine systems, “LargeSMS”). Up until 2021, Ponsse manufactured two large dual machines (Wisent Dual and Buffalo Dual), but a low demand at that point in time lead to its discontinuation. However, the adoption of CCF in Nordic boreal forests has grown substantially since 2021, so we postulate that there might already be, and will continue to be, a strong enough demand for LargeSMS in Nordic forestry to warrant their commercialization and reintroduction (Boson 2025).

6 Conclusions

Because CCF involves lower total removals per tract compared to RFM, an increased share of CCF harvesting in the Nordics will most likely challenge the cost-efficiency of TMS. However, today’s commercially available SMS (SmallSMS) cannot harvest large trees (>1 m3 piece size), which is a necessity in CCF. Large forest machines are also necessary to avoid damaging remaining trees when working with the crane extended. There is thus a need for large-sized SMS (LargeSMS). Future studies on SMS should focus on simulating alternative harvesting systems during CCF and conducting time studies on existing second-hand LargeSMS (e.g. Ponsse Dual) in CCF stands for improved quality of SMS modelling and input data. Nevertheless, with the rise of CCF, we postulate that there might already be a strong enough demand for LargeSMS in Nordic forestry to warrant their commercialization.

Authors’ contributions

BTE: Conceptualization; Data gathering; Writing – original draft; Writing – review & editing.

JM: Conceptualization; Data gathering; Text review & commentary.

KK: Data gathering; Text review & commentary.

Declaration of the use of generative artificial intelligence and AI-assisted technologies in the writing process

During the preparation of this work, the corresponding author used ChatGPT in order to check the grammar of approximately 7 sentences. After using this tool, the author reviewed and edited the content as needed and takes full responsibility for the content of the publication.

Acknowledgements

Thanks to Simon Berg for providing Norwegian background information/data and for comments on earlier manuscript versions.

Funding

Funding for this work was provided by Stiftelsen SLO-fonden, SLU’s Faculty of Forest Sciences and Skogforsk. The work was also funded by the Research Council of Finland through the UNITE flagship (decision numbers 357906 and 359172).

References

Affenzeller G, Stampfer K (2007) Comparison of integrated with conventional harvester-forwarder-concepts in thinning operations. In: Proceedings of the International Mountain Logging and 13th Pacific Northwest Skyline Symposium, April 2007. Corvallis, Oregon, USA, pp 32–38.

Bergkvist I (2010) Drivare i svenskt skogsbruk: erfarenheter och möjligheter till utveckling. [The harwarder in Swedish forestry: experiences and potential for further development]. Skogforsk, Redogörelse nr 1.

Bergkvist I, Hallonborg U, Nordén B (2002) Valmet 801 Combi during thinning with fixed load space for standard log lengths. Skogforsk, Arbetsrapport 518.

Bergqvist M, Danielsson G, Fjeld D, Gunnarsson S, Larsson M, Larsson R, Lindström D, Noreland D, Löfstedt J, Persson J, Pettersson D, Sunesdotter E, Svedin E, Thureson K, Wiborgh T (2023) Nulägesbeskrivning av enskilda vägar med inriktning på skogsbrukets transporter. [Description of the current situation of private roads with a focus on forestry transports]. Skogsstyrelsen, Rapport 2023/18.

Boson S (2025) Drivning i svenskt skogsbruk: skogsföretag och maskintillverkares inställning till stora enmaskinsystem. [Logging in Swedish forestry: Forest companies’ and machine manufacturers’ attitudes to large Single Machine Systems]. Institutionen för skogens biomaterial och teknologi, Swedish University of Agricultural Sciences, Rapport 2025:03. https://stud.epsilon.slu.se/21661/.

Cedergren J, Holmström E, Routa J, Huuskonen S, Kuehne C, Rautio P (2025) Introduction. In: Rautio P, Routa J, Huuskonen S, Holmström E, Cedergren J, Kuehne C (eds) Continuous cover forestry in boreal Nordic countries. Managing Forest Ecosystems 45, Springer Cham. https://doi.org/10.1007/978-3-031-70484-0_1.

Dong X, Mendoza-Trejo O, Morales DO, Lindroos O, La Hera P (2020) Simulation-based comparison between two crane-bunk systems for loading work when considering energy-optimal motion planning. Int J For Eng 31: 70–77. https://doi.org/10.1080/14942119.2019.1653027.

Eliasson L, Bengtsson J, Cedergren J, Lageson H (1999) Comparison of single-grip harvester productivity in clear- and shelterwood cutting. J For Eng 10: 43–48. https://doi.org/10.1080/08435243.1999.10702723.

Eliasson L, Grönlund Ö, Lundström H, Sonesson J (2021) Harvester and forwarder productivity and net revenues in patch cutting. Int J For Eng 32: 3–10. https://doi.org/10.1080/14942119.2020.1796433.

Erefur C (2010) Regeneration in continuous cover forestry systems. [Doctoral thesis]. Swedish University of Agricultural Sciences, Acta Universitatis Agriculturae Sueciae 2010:42. http://pub.epsilon.slu.se/2277/.

Hallonborg U (1998) Drivare – en analys av maskiner för avverkning och transport. [Harwarders – an analysis of machines for cutting and extraction]. Skogforsk, Arbetsrapport 392.

Hallonborg U, Nordén B, Lundström H (2005) Metodstudie av Ponsse Dual i slutavverkning. [Methods study on the Ponsse Dual machine in final felling]. Skogforsk, Resultat nr 12.

Hänninen H, Karppinen H, Leppänen J (2011) Suomalainen metsänomistaja 2010. [Finnish forest owners in 2010]. Working Papers of the Finnish Forest Research Institute 208. https://urn.fi/URN:ISBN:978-951-40-2317-0.

Hildt E, Leszczuk A, Mac Donagh P, Schlichter T (2020) Time consumption analysis of forwarder activities in thinning. Croat J For Eng 41: 13–24. https://doi.org/10.5552/crojfe.2020.615.

Jonsson R (2015) Performance and costs in selective harvesting with harvester and forwarder. Skogforsk, Arbetsrapport 863.

Jonsson R, Jönsson P, Manner J, Björheden R, Lundström H (2016) Performance and costs for the Komatsu X19 harwarder compared to Komatsu 941/895 harvester/forwarder in large-size final felling. Skogforsk, Arbetsrapport 912.

Jonsson R, Mörk A, Manner J, Englund M (2020) Development potential for harwarders – results from a workshop with harwarder operators. Skogforsk, Arbetsrapport 1058.

Jylhä P, Väätäinen K, Rieppo K, Asikainen A (2006) Aines- ja energiapuun hakkuu ja lähikuljetus korjureilla. Kirjallisuuskatsaus. [Cutting and forwarding of roundwood and energy wood with harwarders. Literature review]. Working Papers of the Finnish Forest Research Institute 34. https://urn.fi/URN:ISBN:978-951-40-2012-4.

Kärhä K, Poikela A, Rieppo K, Imponen V, Keskinen S, Vartiamäki T (2007) Korjurit ainespuun korjuussa. [Harvesting industrial roundwood with harwarders]. Metsätehon raportti 200. https://www.metsateho.fi/wp-content/uploads/2015/02/metsatehon_raportti_200.pdf.

Kärhä K, Poikela A, Palander T (2018) Productivity and costs of harwarder systems in industrial roundwood thinnings. Croat J For Eng 39: 23–33. https://hrcak.srce.hr/193547.

Korpunen H, Nuutinen Y, Jylhä P, Eliasson L, Granhus A, Laitila J, Hoffmann S, Muhonen T (2025) Harvesting of continuous cover forests. In: Rautio P, Routa J, Huuskonen S, Holmström E, Cedergren J, Kuehne C (eds) Continuous cover forestry in boreal Nordic countries. Managing Forest Ecosystems 45, Springer Cham, pp 109–124. https://doi.org/10.1007/978-3-031-70484-0_6.

Kulju I, Niinistö T, Peltola A, Räty M, Sauvula-Seppälä T, Torvelainen J, Uotila E, Vaahtera E (2023) Metsätilastollinen vuosikirja 2022. [Finnish statistical yearbook of forestry 2022]. National Forest Resources Institute Finland, Helsinki. https://urn.fi/URN:ISBN:978-952-380-584-2.

Kuuluvainen T, Tahvonen O, Aakala T (2012) Even-aged and uneven-aged forest management in boreal Fennoscandia: a review. Ambio 41: 720–737. https://doi.org/10.1007/s13280-012-0289-y.

Laitila J, Repola J, Holmström E (2025) Time consumption models for predicting harvester productivity when selection cutting, thinning from below, and clearcutting Scots pine-dominated stands in Finnish Lapland. Int J For Eng 36: 178–193. https://doi.org/10.1080/14942119.2024.2448935.

Luke (2025) Natural Resources Institute Finland (Luke) database. https://www.luke.fi/en/statistics/silvicultural-and-forest-improvement-work. Accessed 28 Aug 2025.

Lundqvist R (2023) Final report: harwarder in final fellings. Skogforsk, Arbetsrapport 1171.

Manner J, Mörk A, Arlinger J, Jonsson R (2019) Harwarder productivity based on load-wise assortment distribution – field study on the harwarder prototype Komatsu X19. Skogforsk, Arbetsrapport 1013.

Ringdahl O, Hellström T, Lindroos O (2012) Potentials of possible machine systems for directly loading logs in cut-to-length harvesting. Can J For Res 42: 970–985. https://doi.org/10.1139/x2012-036.

Sirén M, Aaltio H (2003) Productivity and costs of thinning harvesters and harvester-forwarders. Int J For Eng 14: 39–48. https://doi.org/10.1080/14942119.2003.10702468.

Skogsstyrelsen (2024) Fellings. Official statistics of Sweden. https://www.skogsstyrelsen.se/statistik/statistik-efter-amne/avverkning/. Accessed 28 Aug 2025.

Spinelli R, Magagnotti N (2013) The effect of harvest tree distribution on harvesting productivity in selection cuts. Scan J For Res 28: 701–709. https://doi.org/10.1080/02827581.2013.821517.

Statistics Norway (2025) Forest roads. Statistisk sentralbyrå (SSB). https://www.ssb.no/en/statbank/table/06057/. Accessed 28 Aug 2025.

Ström P (2008) Drivarens produktivitet vid lossningsarbete. [Harwarder productivity at unloading]. Institutionen för skoglig resurshushållning, Swedish University of Agricultural Sciences, Arbetsrapport 205. https://stud.epsilon.slu.se/12067/.

Talbot B (2016) FORDEL – en undersøkelse av driftsforholdene omkring terrenggående taubaner. [FORDEL – a study of operating conditions for terrain-going cable yarders]. NIBIO Report 2/72. ISBN 9788217016441.

Talbot B, Suadicani K (2015) Quantifying the influence of geo-spatial forest distribution on machinery management. Baltic For 21: 340–348.

Talbot B, Nordfjell T, Suadicani K (2003) Assessing the utility of two integrated harvester-forwarder machine concepts through stand-level simulation. Int J For Eng 14: 31–43. https://doi.org/10.1080/14942119.2003.10702476.

Väätäinen K, Hyvönen P, Kankaanhuhta V, Laitila J, Hirvelä H (2021) The impact of fleet size, harvesting site reserve, and timing of machine relocations on the performance indicators of mechanized CTL harvesting in Finland. Forests 12, article id 1328. https://doi.org/10.3390/f12101328.

Väätäinen K, Kostensalo J, Anttila P, Savinainen M, Kaakkurivaara T, Pohjankukka J, Lumberg V, Ala-Ilomäki J, Laitila J, Lindeman H, Lopatin E, Sikanen L (2025) Toward a digital twin of forest roads – road weather stations for monitoring road condition and trafficability in Eastern Finland. Int J For Eng: 1–14. https://doi.org/10.1080/14942119.2025.2533086.

Wester F, Eliasson L (2003) Productivity in final felling and thinning for a combined harvester-forwarder (harwarder). Int J For Eng 14: 45–51. https://doi.org/10.1080/14942119.2003.10702477.

Total of 39 references.